Preparation method and application of seal cholic acid

A technology of seal and cholic acid, applied in the directions of steroids, organic chemistry, etc., can solve the problem of not separating and utilizing the cholic acid of seal, achieve good economic value and application prospect, alleviate the problem of insufficient supply, and be easy to industrialize production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

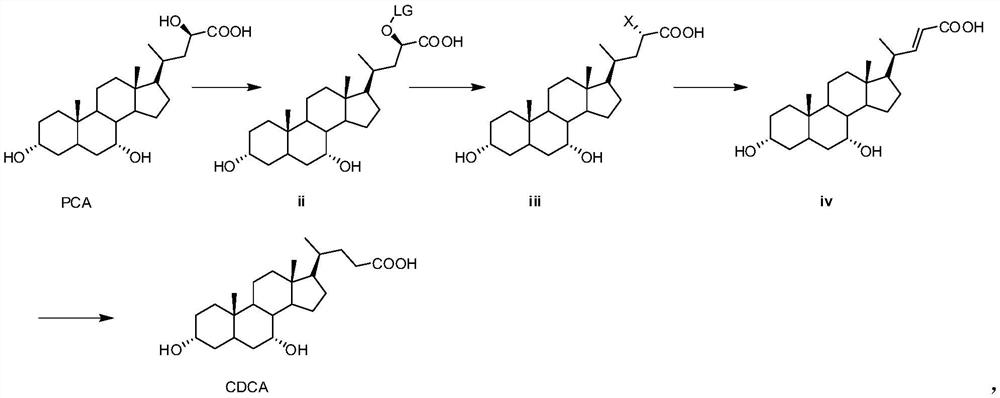

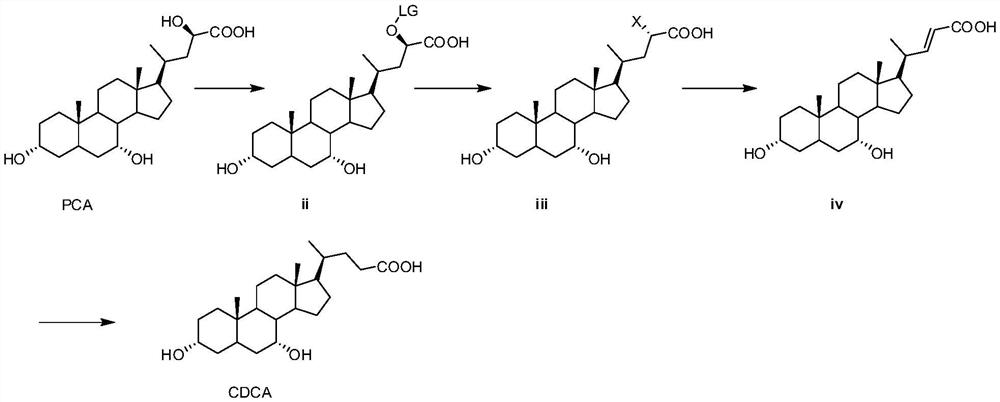

Method used

Image

Examples

preparation example 1

[0022] Grease removal: put 54.8kg of powdered duck gall paste into the reaction kettle, then add 160kg of n-heptane, reflux and stir for 2 hours, then reduce the temperature and suction filter and dry to obtain 45.75kg of solid.

[0023] Alkali-soluble decolorization and acidification: 6kg of sodium hydroxide is dissolved in 100kg of water, add 45.75kg of duck gall paste obtained in the previous step, stir to dissolve, then add 3kg of hydrogen peroxide, reflux and stir for 1 hour, then drop to room temperature, add 300kg ethyl acetate, adjusted to pH=2 with concentrated hydrochloric acid, and separated to obtain an ethyl acetate layer for later use.

Embodiment 1

[0025] PCA magnesium salt preparation: add 5% magnesium acetate solution 250kg to the standby ethyl acetate layer that obtains by preparation example 1 method (55kg powdery duck gall paste, PCA content 32.4%), stir 20min, then centrifuge rapidly, obtain 40kg PCA magnesium salt, content 81.2%.

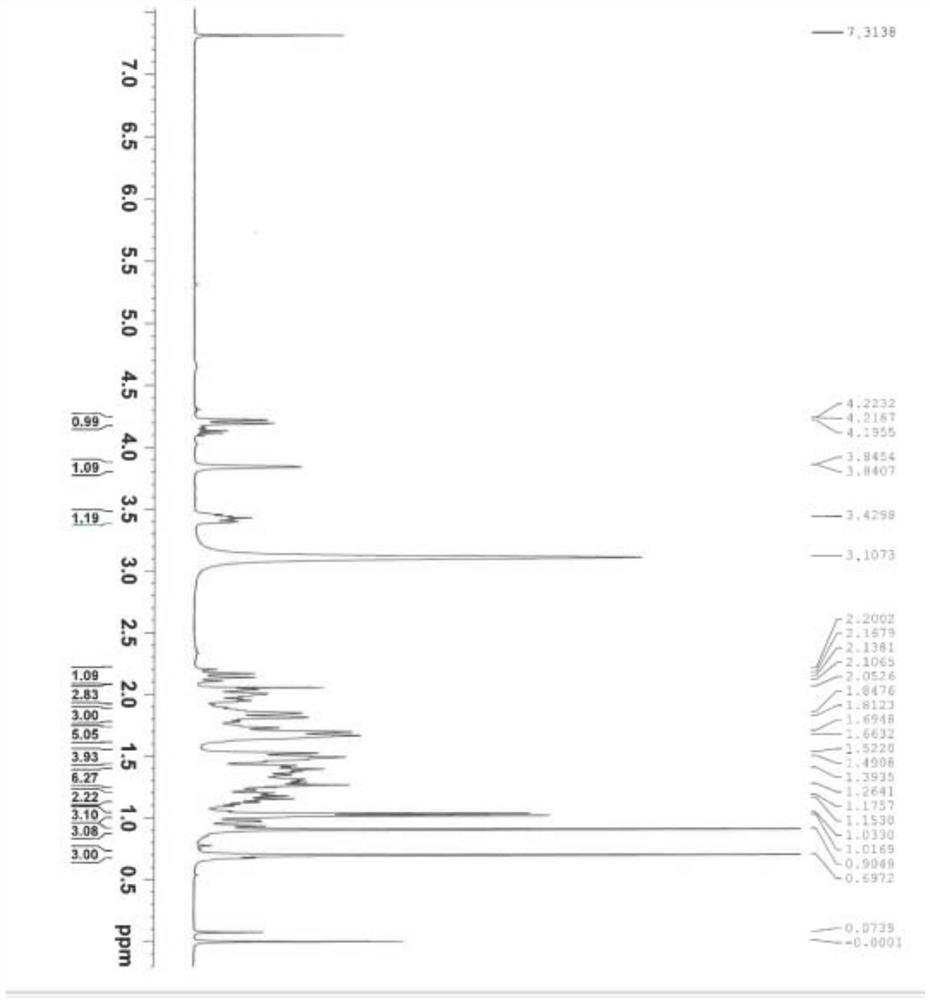

[0026] PCA preparation: Add 40kg of the PCA magnesium salt obtained in the previous step into 200L water, add hydrochloric acid to dissolve and adjust the pH to 2, then add 100kg of ethyl acetate for extraction, separate the liquid, and evaporate the ethyl acetate phase to dryness; then add 50kg of acetic acid Ethyl ester and 50kg of dichloromethane were heated and dissolved, and then slowly dropped to 10°C for crystallization to obtain 11.2kg of PCA finished product with a purity of 97.4%. The nuclear magnetic resonance spectrum is as attached figure 1 .

Embodiment 2

[0028] PCA magnesium salt preparation: add 5% magnesium acetate solution 200kg to the standby ethyl acetate layer that obtains by preparation example 1 method (55kg powdery duck gall paste, PCA content 34.3%), stir 20min, then centrifuge rapidly, obtain 36kg PCA magnesium salt, content 77.1%.

[0029] PCA preparation: Add 36kg of the PCA magnesium salt obtained in the previous step into 180L water, add sulfuric acid to stir and dissolve, and adjust the pH to 1.5, then extract with 90kg of ethyl acetate, separate the liquid, and evaporate the ethyl acetate phase to dryness; then add 45kg of ethyl acetate and 45kg of dichloromethane were heated to dissolve, and then slowly lowered to room temperature at 25°C for crystallization to obtain 7.6kg of finished PCA with a purity of 94.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com