Flexible electromagnetic pole compounding tool

A composite tool and electromagnetic pole technology, which is applied in the field of flexible electromagnetic pole composite tools, can solve problems such as inability to process, tool failure, processing superhard metal materials and metal matrix composite materials that cannot meet the needs of industrialization, etc., and achieve simple technical means easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in further detail below, but the embodiments of the present invention are not limited thereto.

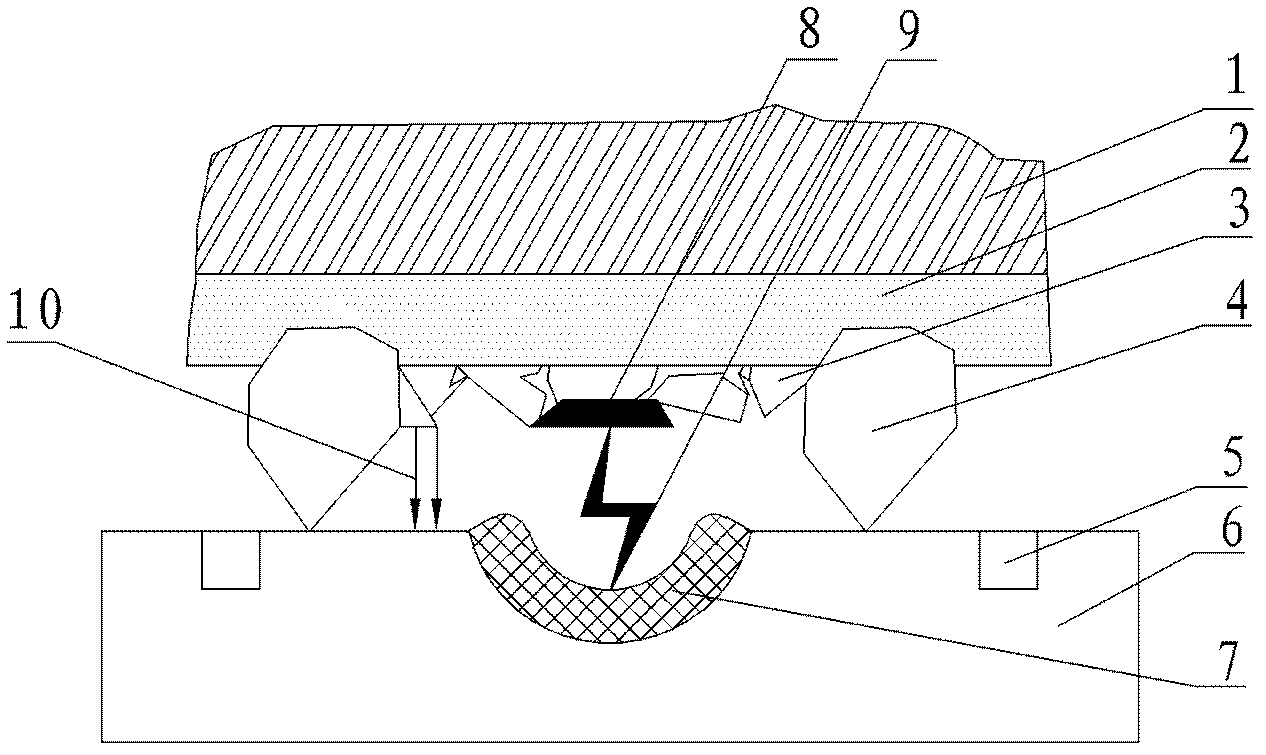

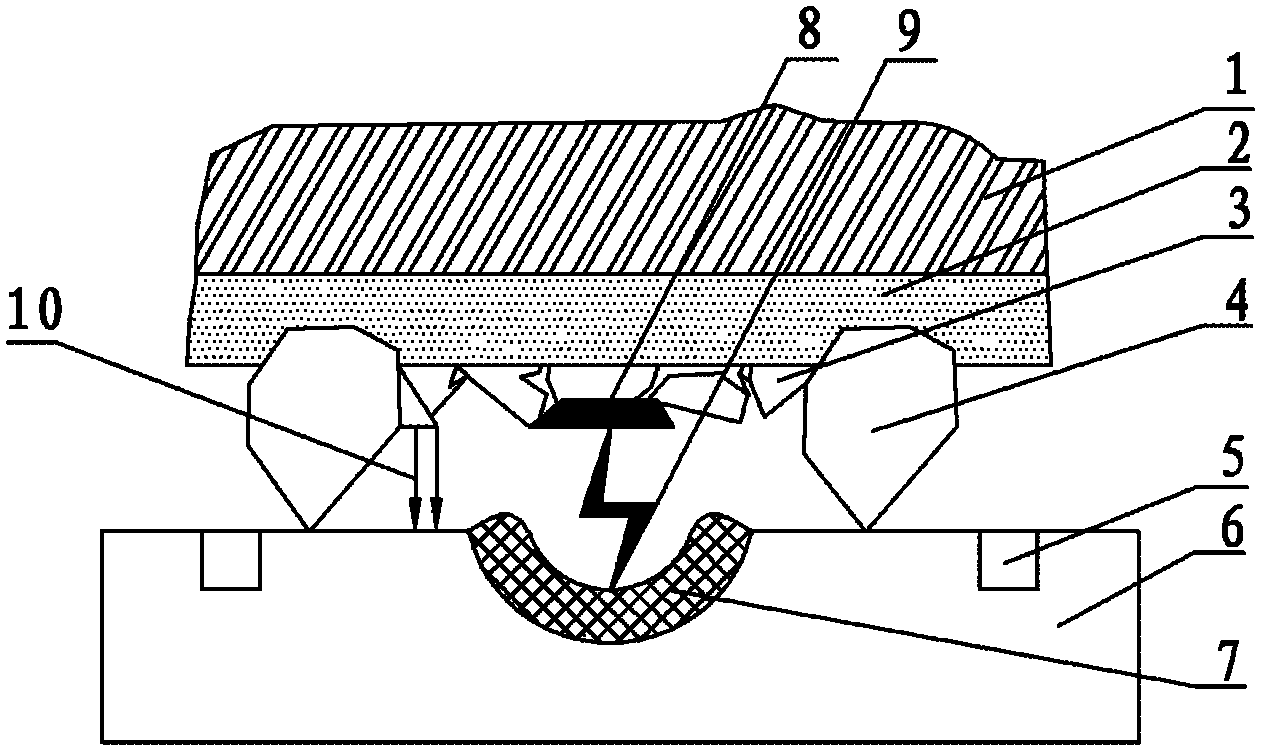

[0022] Such as figure 1 As shown, the flexible electromagnetic pole compound tool of the present invention includes a matrix 1 and an abrasive grain layer of the tool, and the abrasive grain layer includes abrasive grains 4 and an abrasive bond layer 2, and the abrasive grain 4 is connected to the matrix through the abrasive bond layer 2. 1, and the surface of the abrasive bond layer 2 is also adsorbed with magnetic powder particles that induce discharge to form a protective layer 3 of magnetic powder.

[0023] The abrasive grain layer has at least one layer, such as 5 layers, 10 layers, 20 layers and so on. The abrasive grains 4 are several and irregularly distributed throughout the entire abrasive bond layer 2 . The shape of the abrasive grains 4 is rhombus, triangle or irregular polygon.

[0024] Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com