Automatic transmission production line for assembly of passenger car bogie

An automatic transmission and bogie technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems affecting product quality and production efficiency, hidden safety hazards, low production efficiency, etc., to prevent misoperation from damaging equipment or Personal injury accidents, high production efficiency, and overall beautiful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

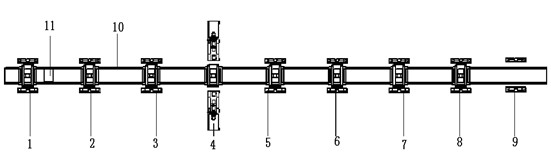

[0027] Such as figure 1 as shown,

[0028] The production line is continuously and sequentially provided with various stations for bogie assembly and processing along the same straight line. The initial station 1 is for hoisting and positioning, the station for installing the traction center mechanism, and the second station 2 is for installing anti-torsion tie rods. station, the third station 3 is the installation station of the rotating arm and the press-fit spring assembly, the fourth station 4 is the station for turning the reverse bogie to the normal position, and the fifth station 5 is the brake air circuit row The installation station, the sixth station 6 is the traction motor cable installation station, the seventh station 7 is the brake brake, parking brake and brake shoe device installation station, the eighth station 8 is the traction motor installation station , The ninth station 9 is the station for the finished bogie to be operated. The basic ground along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com