Vertical/horizontal automatic squeezer

A pressing machine and automatic technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of low efficiency, high energy consumption, high moisture content, etc., and achieve the effect of high efficiency, low energy consumption, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

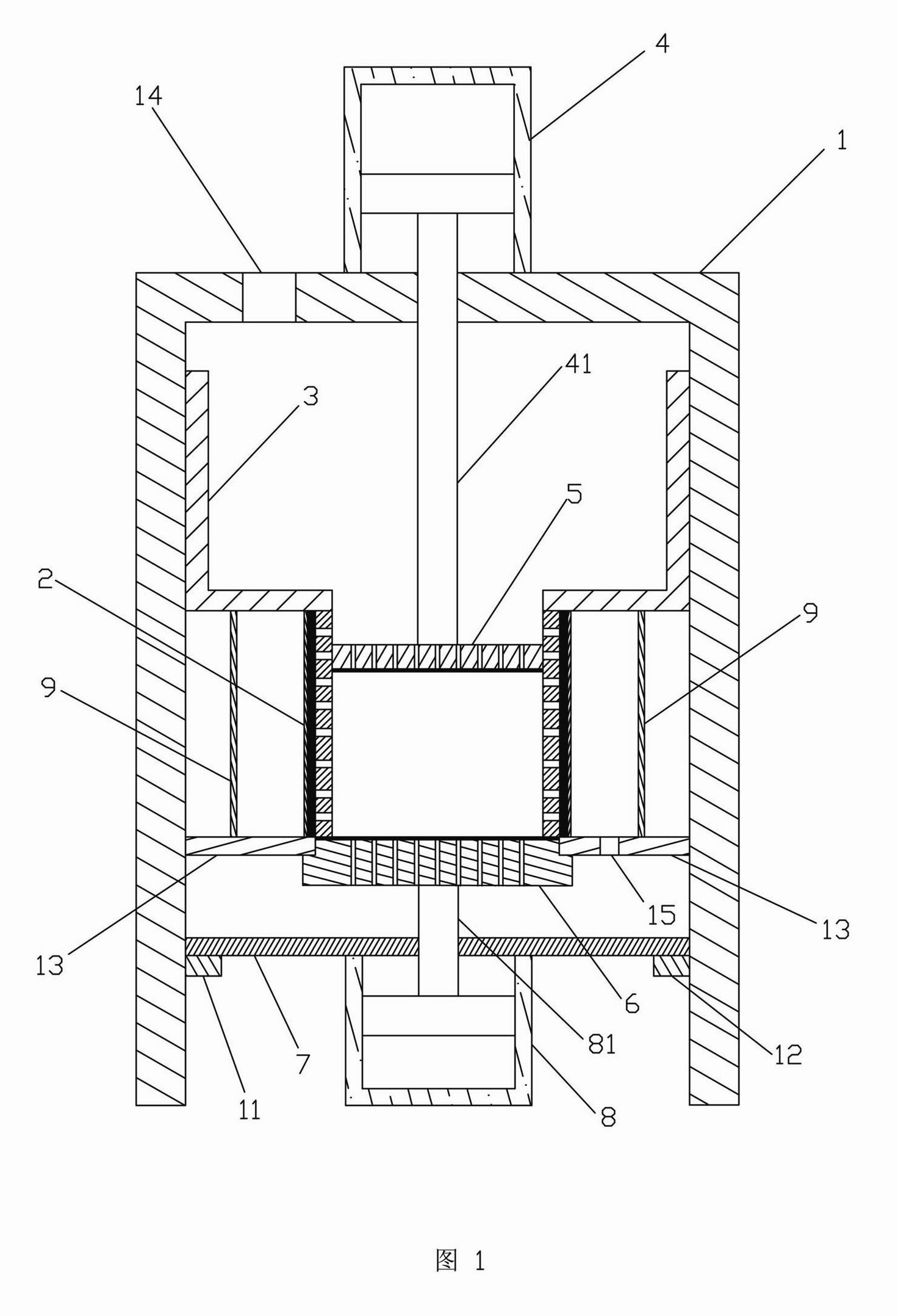

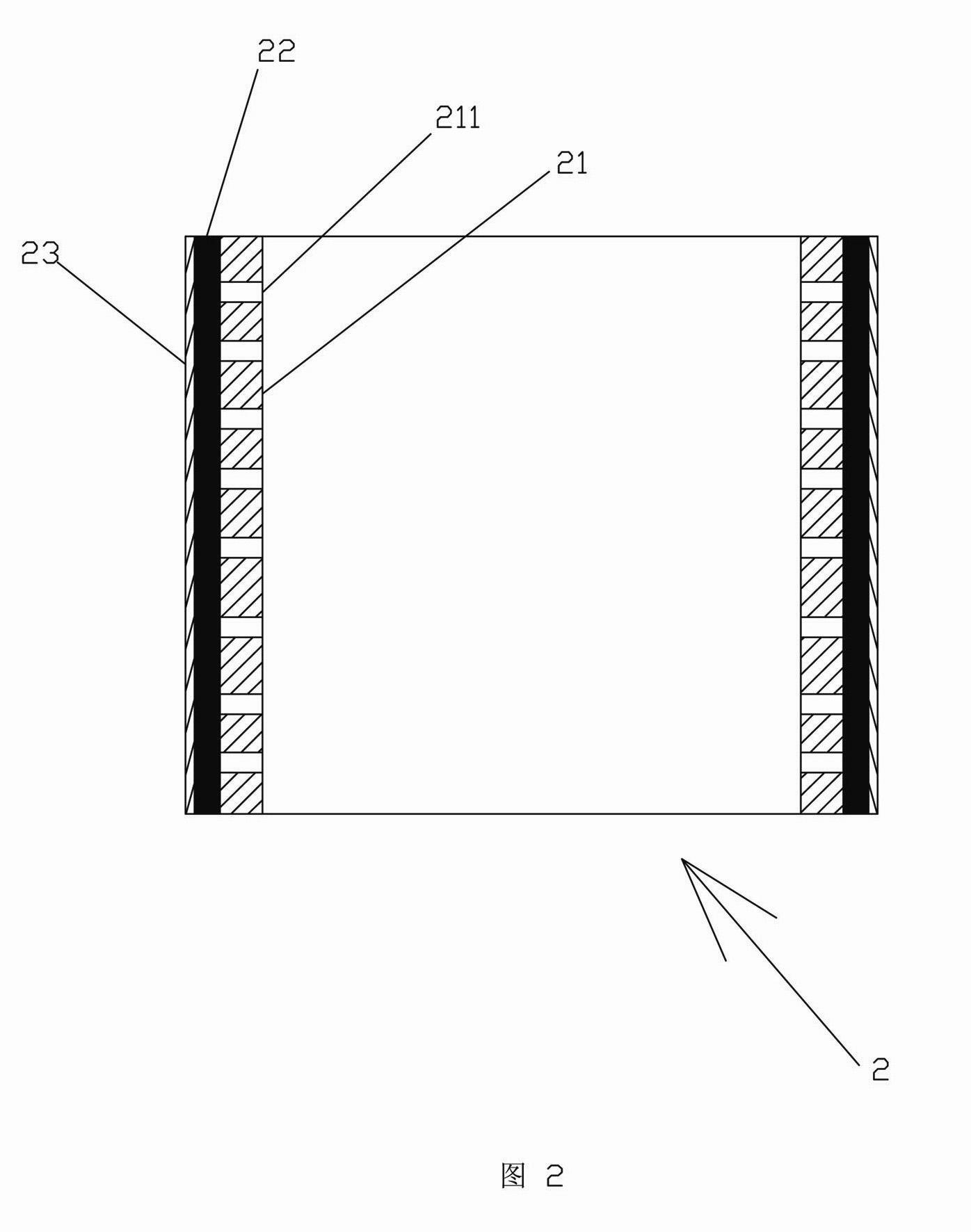

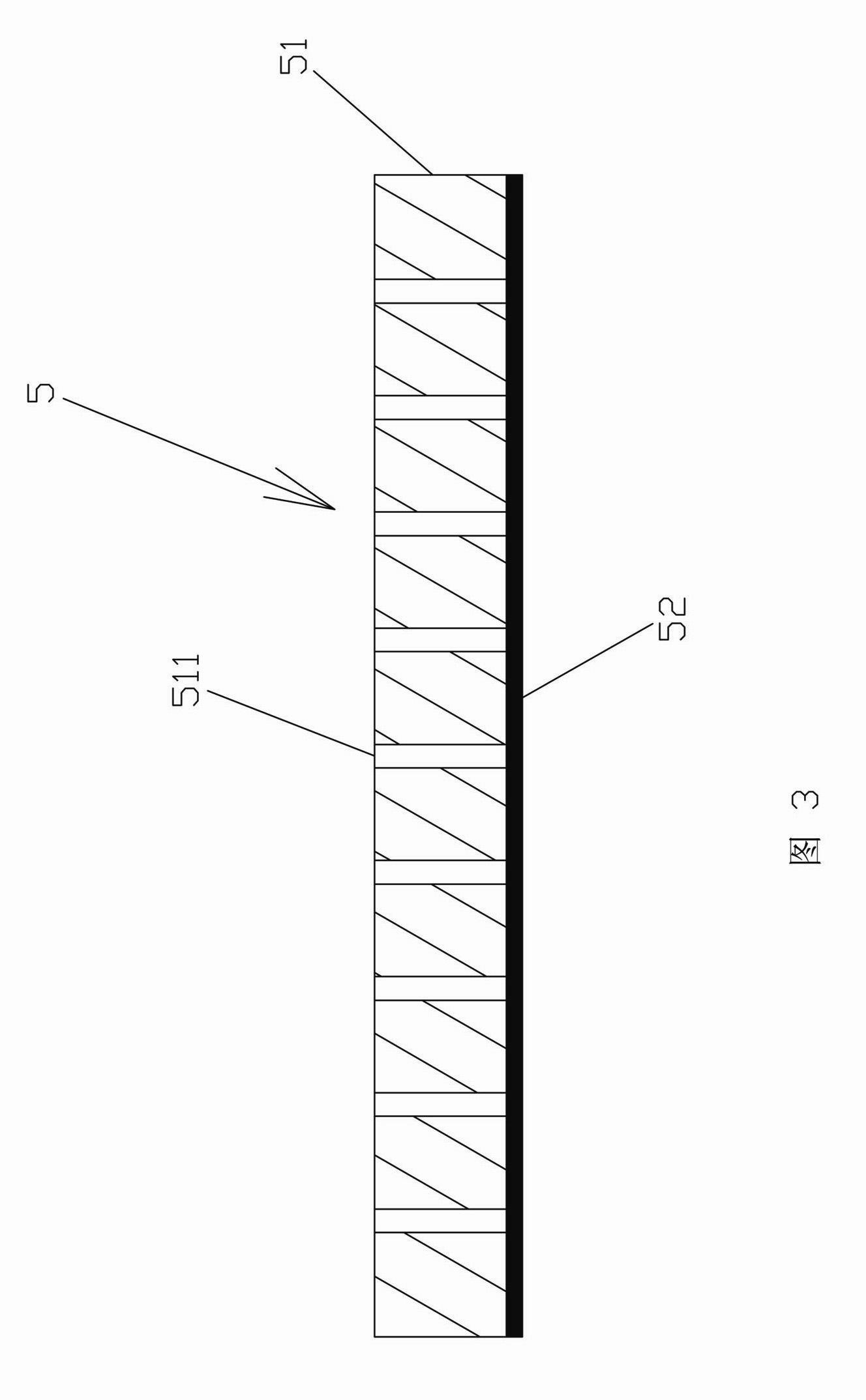

[0030] refer to figure 1 , a vertical automatic press, which includes a vertical frame 1, a press barrel 2 that is straight up and down (that is, both upper and lower ends are open), a slurry barrel 3, an upper hydraulic cylinder 4, a pressure plate 5, and a movable plug Disc 6, horizontal mounting frame 7 and lower hydraulic cylinder 8. The bottom of the vertical frame 1 is provided with two horizontal slide rails 11, 12, and the middle part of the vertical frame 1 is fixed with a horizontal plate 13. The horizontal mounting frame 7 is installed on the slide rails 11, 12, and it can move horizontally on the slide rails 11, 12; The end of the piston rod 81, and the movable blocking plate 6 can move and block the lower end of the squeeze barrel 2, while referring to image 3 The above-mentioned movable blocking plate 6 is composed of a blocking plate body 61 with a stepped surface and a blocking plate filter layer 62 fixed on the upper surface of the blocking plate body 61. T...

Embodiment 2

[0034] refer to Figure 5 , Figure 7 and Figure 8, a horizontal automatic press, which includes a horizontal frame 1', a press barrel 2' that is straight from left to right (that is, both ends of the left and right are open), a total hydraulic cylinder 3', a pressure plate 5', left and right Two movable blocking plates 61', 62', and left hydraulic cylinders 71', 72' and right hydraulic cylinders 73'. The platen 5' is composed of a platen body 51' and platen filter layers 52', 53' fixed on the left and right surfaces of the platen body 51' at the same time. The platen body 51' is evenly distributed with through holes 511', these The diameter of the through hole 511' is between 1-3 cm. In addition, in order to enhance the sealing performance, it is usually necessary to wrap a sealing ring (not shown in the figure) on the side wall of the pressure plate body 51'. The above-mentioned left and right movable blocking plates 61', 62' are composed of a blocking plate body 63' wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com