Manufacture process of bowl-shaped noble metal products and mold for manufacture process

A production process and precious metal technology, which is applied to the production process of precious metal products, can solve the problems of low production cost, inability to produce bowl-shaped precious metal products, etc., and achieve high production efficiency, full pattern, high ornamental value and collection value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

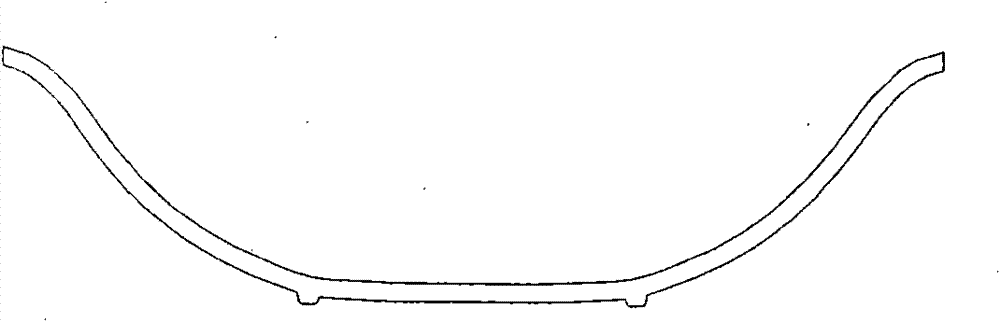

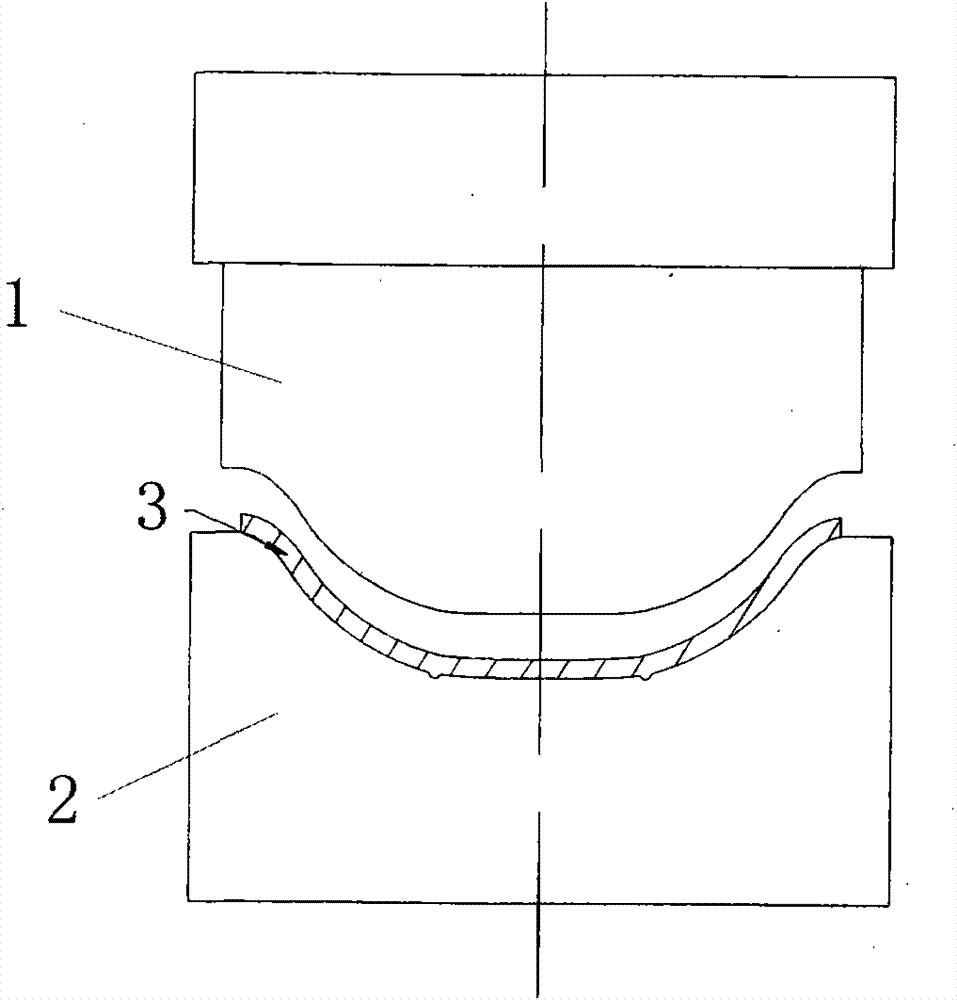

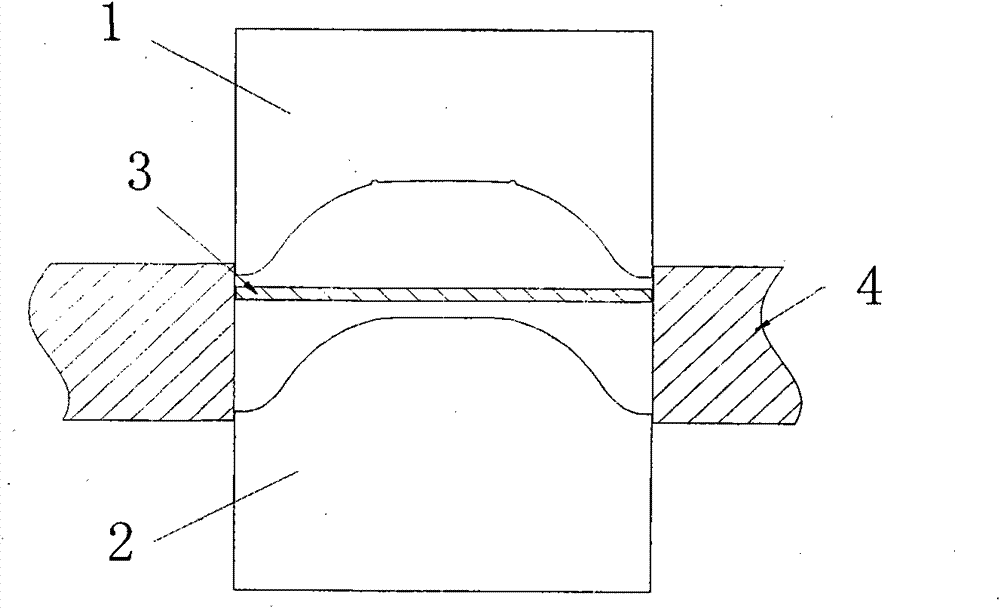

[0036] The present invention takes the preparation of a 50g silver bowl as an example, the diameter of the bowl mouth is 60mm, the diameter of the small surface of the bowl bottom is 22.64mm, and the bowl depth is 15.23mm. First, select the shape parameters of the designed bowl and use the three-dimensional relief design software to design and generate the surface shape parameters of the convex and concave surface of the bowl. In order to make the shape of the bowl closer to the real bowl, the surface of the bowl is composed of three arcs. Swept tangentially. In order to make the bowl mold fit better during the stamping process, the product pattern is fully pressed. The thickness of the blank cake is calculated to be 1.5mm. Therefore, when designing the bowl lateral surface radius, the curved surfaces of the punch and the concave mold The radius is designed to be different values. For example, the radius of the curved surface tangent to the bowl bottom of the punch is 22.55mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com