Rectilinear propulsion ship

A straight-line, straight-line technology, applied in the direction of rotary propellers, ship propulsion, propulsion components, etc., can solve the problems of safety, energy saving, efficiency improvement, non-coincidence with the ship's longitudinal center of gravity, and low efficiency. Effects of propulsion performance and energy conversion efficiency, energy consumption reduction, drag reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

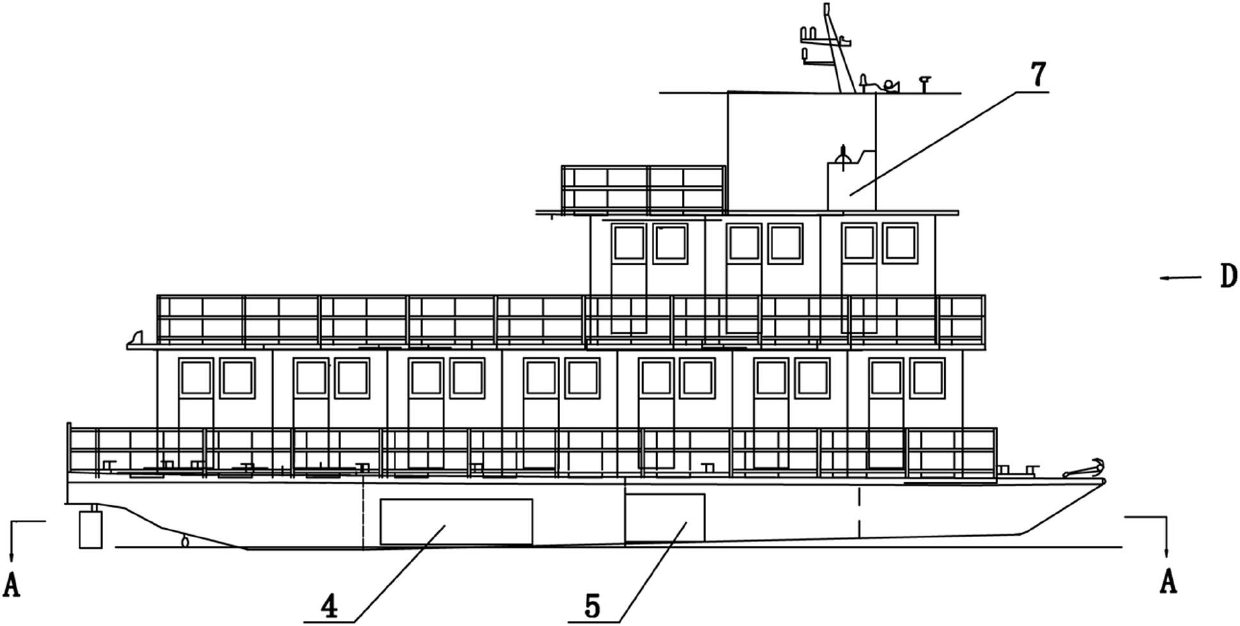

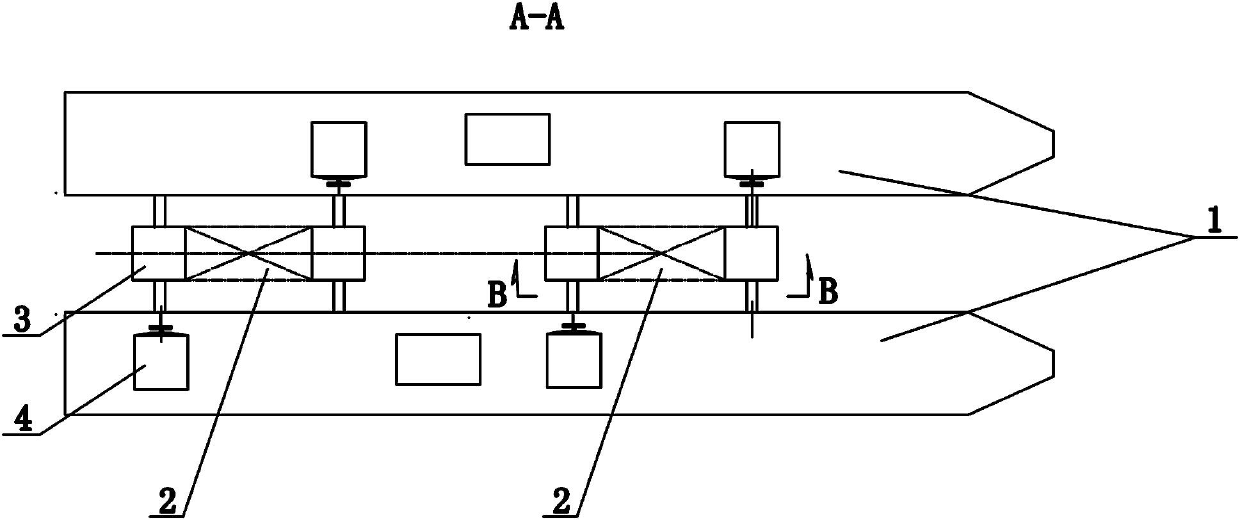

[0031] Such as figure 1 Among them, a linear propulsion ship includes a hull 1, and the hull 1 is provided with at least one set of linear blade drive devices;

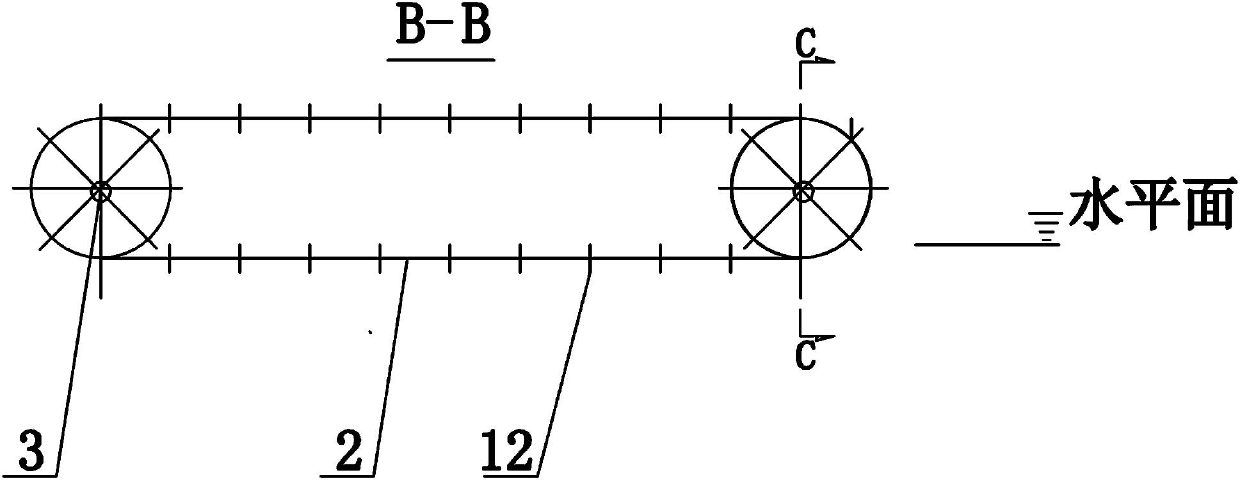

[0032] Such as image 3 , Figure 4 Among them, in the linear paddle driving device, at least two transmission wheels 3 are connected by a linear paddle belt 2, and a plurality of paddles 12 are arranged on the linear paddle belt 2.

[0033] Such as Figure 6 Among them, the transmission wheels 3 are respectively directly connected with the motor 4 , the motor 4 is connected with the frequency conversion controller 5 , the frequency conversion controller 5 is connected with the console 7 , and the console 7 is connected with the power supply 6 .

[0034] The motor 4 is a brushless doubly-fed motor or a wound AC asynchronous motor.

[0035] Such as Figure 7 In the above-mentioned multiple sets of linear paddle drive devices, each motor 4 is connected to each other in parallel.

[0036] Utilize the operating hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com