Epoxy resin composition for semiconductor packaging and preparation method thereof

A technology of epoxy resin and composition, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., and can solve the difficulties of processing or recycling halogen-containing wastes, metabolic disorders, restrictions on the use of halogen-containing flame retardants, etc. problems, to achieve the effect of excellent flow performance, enhanced stress relief, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

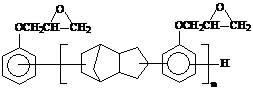

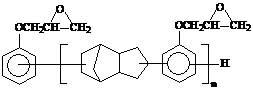

[0045] Example 1. An epoxy resin composition for semiconductor packaging, which includes: epoxy resin, curing agent, curing agent accelerator and inorganic filler; the epoxy resin contains the following formula (1) and formula (2) The epoxy resin described:

[0046]

[0047] Formula 1)

[0048]

[0049] Formula (2)

[0050] Among them: n is a positive integer of 1-12;

[0051] The weight of described epoxy resin accounts for 1-25% of the epoxy resin composition gross weight;

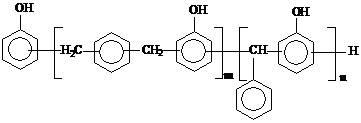

[0052] The curing agent is the phenolic resin described in formula (6),

[0053]

[0054] Formula (6)

[0055] Wherein m and n are both positive integers of 1-12;

[0056] The weight of described curing agent accounts for 1-25% of epoxy resin composition gross weight;

[0057] It also contains liquid nitrile rubber ETBN with epoxy functional group, and the weight of the liquid nitrile rubber ETBN with epoxy functional group accounts for 0.3-2.5% of the epoxy resin composition gross weigh...

Embodiment 2

[0059] Example 2. An epoxy resin composition for semiconductor packaging, which includes: epoxy resin, curing agent, curing agent accelerator and inorganic filler; the epoxy resin contains the following formula (1) and formula (2) The epoxy resin described:

[0060]

[0061] Formula 1)

[0062]

[0063] Formula (2)

[0064] Among them: n is a positive integer of 1-12;

[0065] The weight of described epoxy resin accounts for 1-25% of the epoxy resin composition gross weight;

[0066] The curing agent is a phenolic resin, which contains the phenolic resin described in formula (6), and it also contains one or more of the phenolic resins represented by formula (3), formula (4), and formula (5):

[0067]

[0068] Formula (3)

[0069]

[0070] Formula (4)

[0071]

[0072] Formula (5)

[0073]

[0074] Formula (6)

[0075] Wherein m and n are both positive integers of 1-12;

[0076] The weight of described curing agent accounts for 1-25% of epoxy resin ...

Embodiment 3

[0079] Example 3. In the epoxy resin composition for semiconductor encapsulation described in embodiment 1 or 2: the ratio of the epoxy equivalent in the epoxy resin to the hydroxyl equivalent in the phenolic resin is 0.5-1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com