Internal-combustion permanent-magnet linear power generation device

A permanent magnet linear and power generation device technology, applied in the direction of electromechanical devices, electrical components, machines/engines, etc., can solve the problems of low power density, high power density, difficulty in ensuring manufacturing accuracy and long-term reliability, and avoid lead wire movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

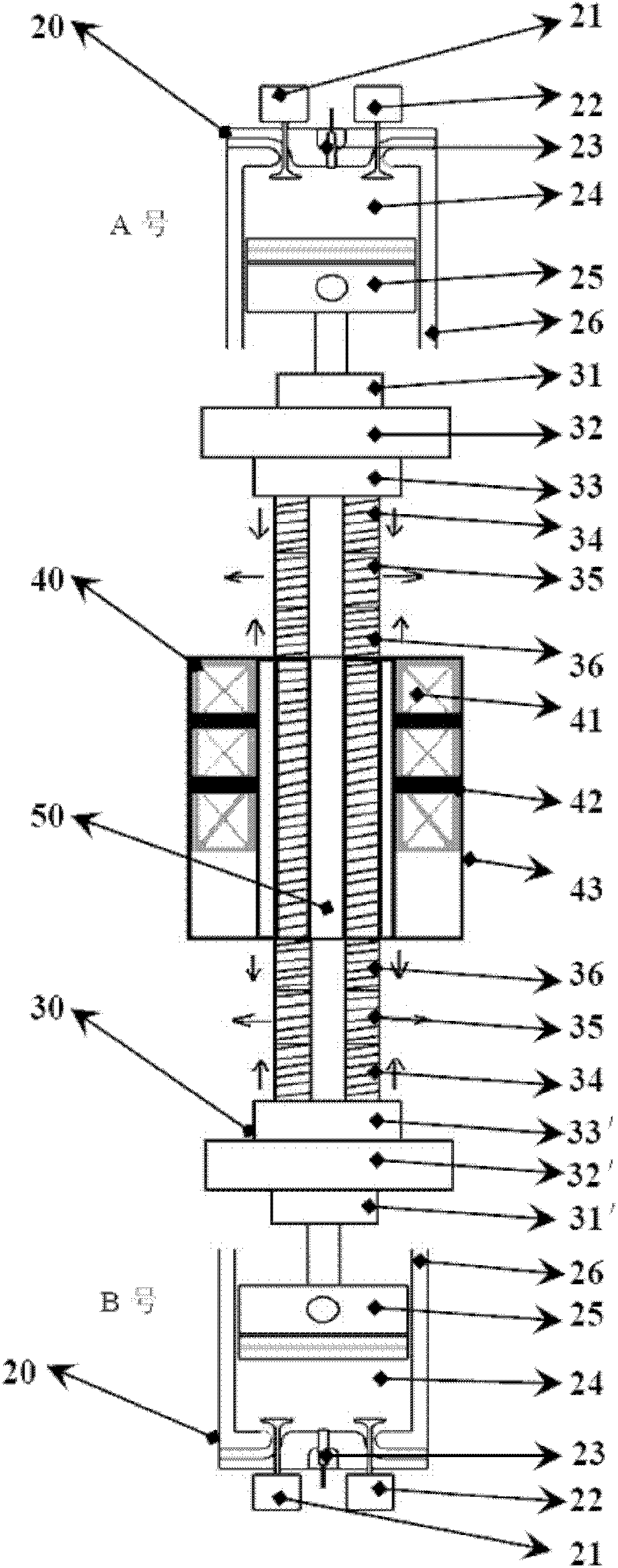

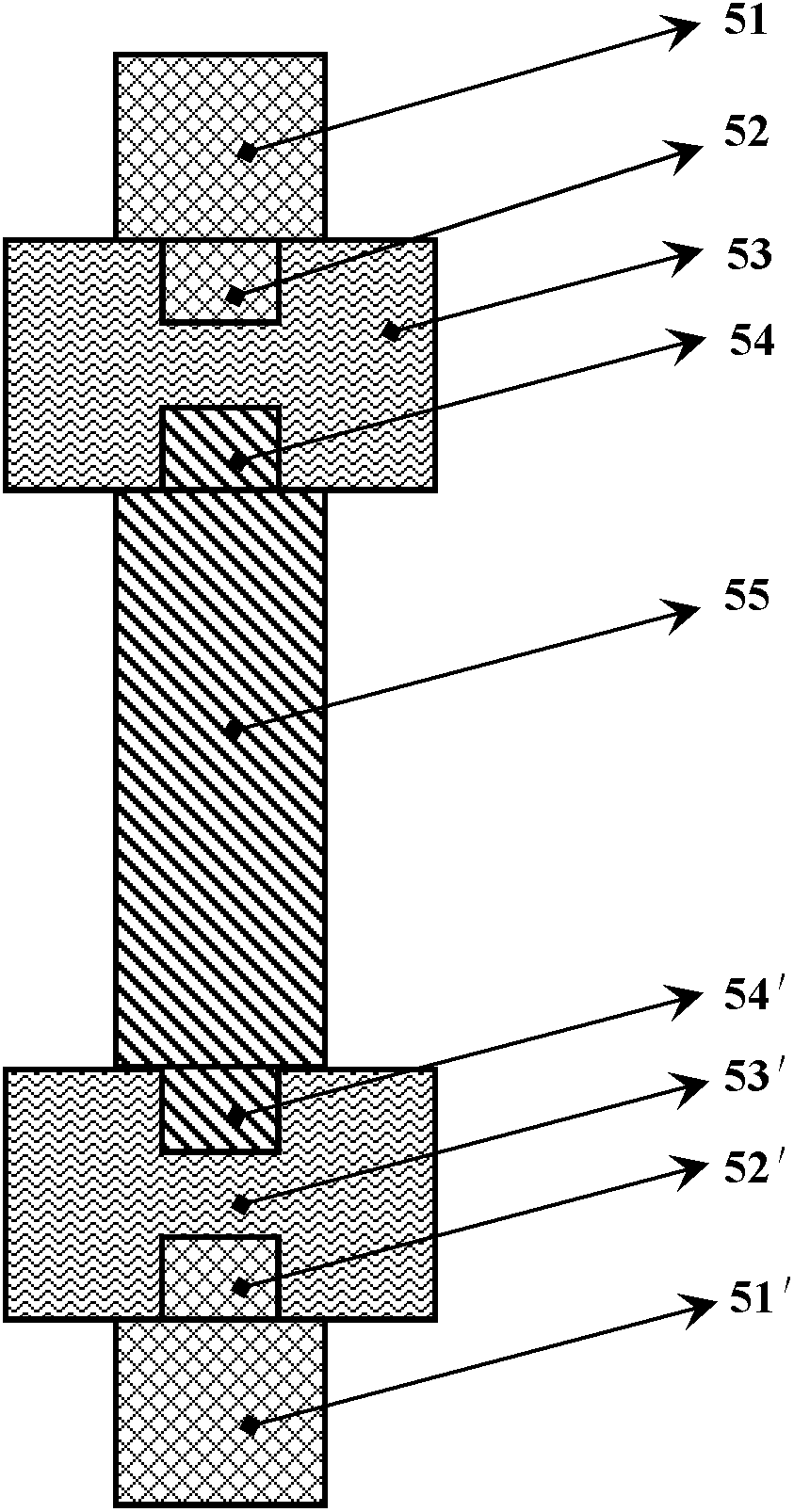

[0021] figure 1 It is a structural schematic diagram of an embodiment of the internal combustion permanent magnet linear power generation device of the present invention, figure 2 yes figure 1 The schematic diagram of the structure of the moving rod used in the embodiment, where the reference signs are:

[0022] Two-stroke internal combustion chamber 20, permanent magnet mover 30, coil stator 40, moving rod 50, electromagnetic valve 21, electromagnetic valve 22, igniter 23, combustion chamber 24, piston 25, box body 26, first compression nut 31, The second compression nut 31', the first group of heat dissipation rings 32, the second group of heat dissipation rings 32', the first group of heat insulation rings 33, the second group of heat insulation rings 33', the axially magnetized permanent magnet rings 34, the diameter Directly magnetized permanen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com