Internal and external truss type three-frame micro-mechanical gyro structure

A micro-mechanical gyro and three-frame technology, applied in the direction of gyro effect for speed measurement, gyro/steering sensing equipment, measuring devices, etc., to achieve the effect of minimizing mass, reducing coupling error, and improving gyro sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

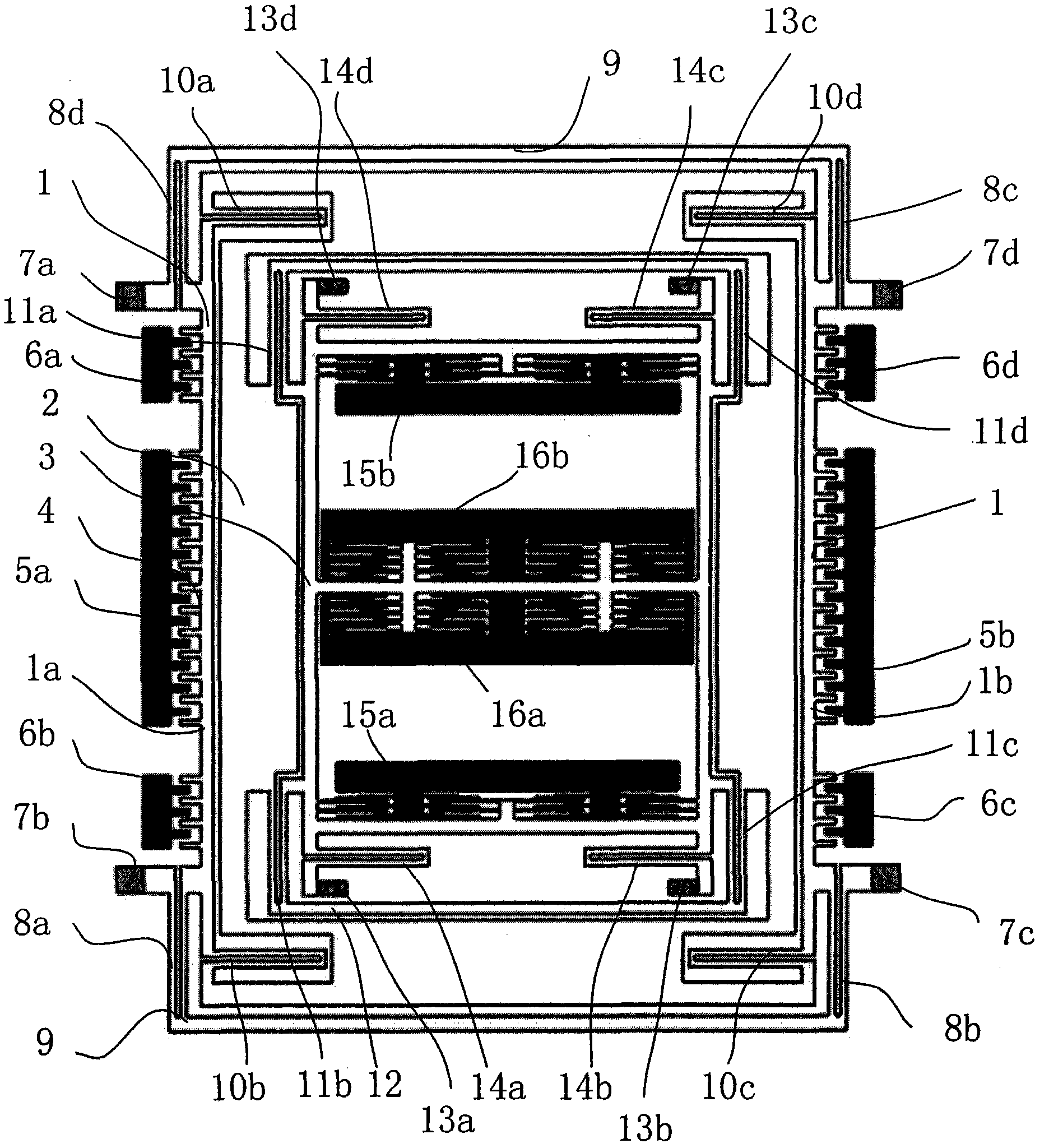

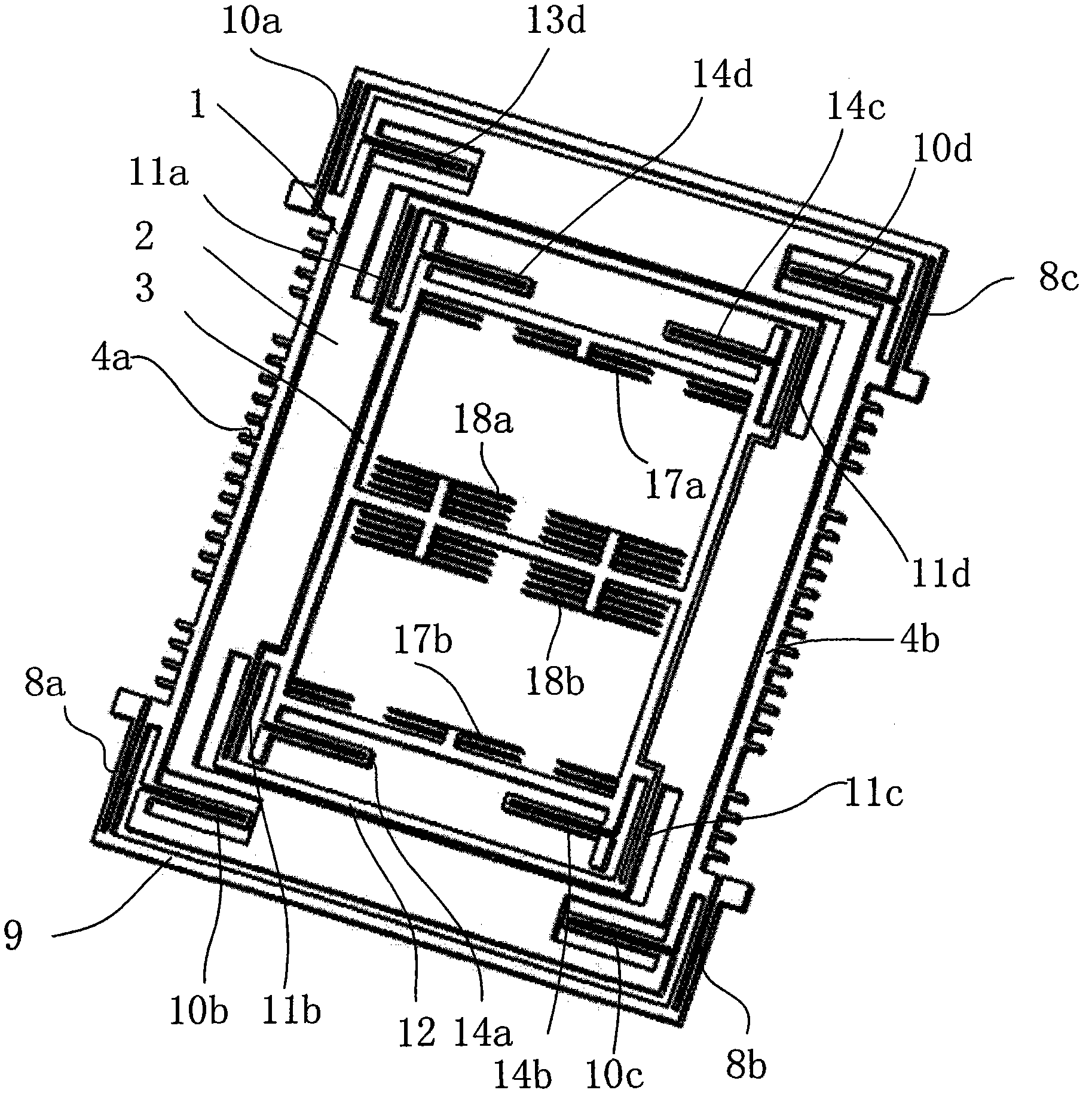

[0017] Such as figure 1 As shown in 2, the present invention includes: the outer frame is the driving part of the gyroscope structure, and the outer frame is connected as a complete whole by the drive units 1 separated on both sides of the structure through the outer frame truss beam 9. The driving force on the outer frame is applied by electrodes 5a and 5b and the variable-area comb-teeth electrodes formed by corresponding comb teeth on the driving unit 1 . The electrodes 5a, 5b and the corresponding comb teeth are driving electrodes. Electrodes 6a, 6b, 6c, 6d are drive feedback electrodes, wherein 6a, 6b are connected in parallel, 6c, 6d are connected in parallel to increase the feedback capacitance value, and the left and right electrodes form differential capacitance. The outer frame is connected to fixed anchor points through elastic beams 8a, 8b, 8c, 8d, and the fixed anchor points are 7a, 7b, 7c, and 7d.

[0018] The middle frame 2 is a Coriolis mass frame, and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com