Manufacturing method and application method of Pt-Ag alloy nanoparticle enzyme-free glucose sensor electrode

A technology of alloy nanoparticles and glucose sensor, which can be used in instruments, scientific instruments, electrochemical variables of materials, etc., and can solve the problems of high cost, poor selectivity, and easy deactivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

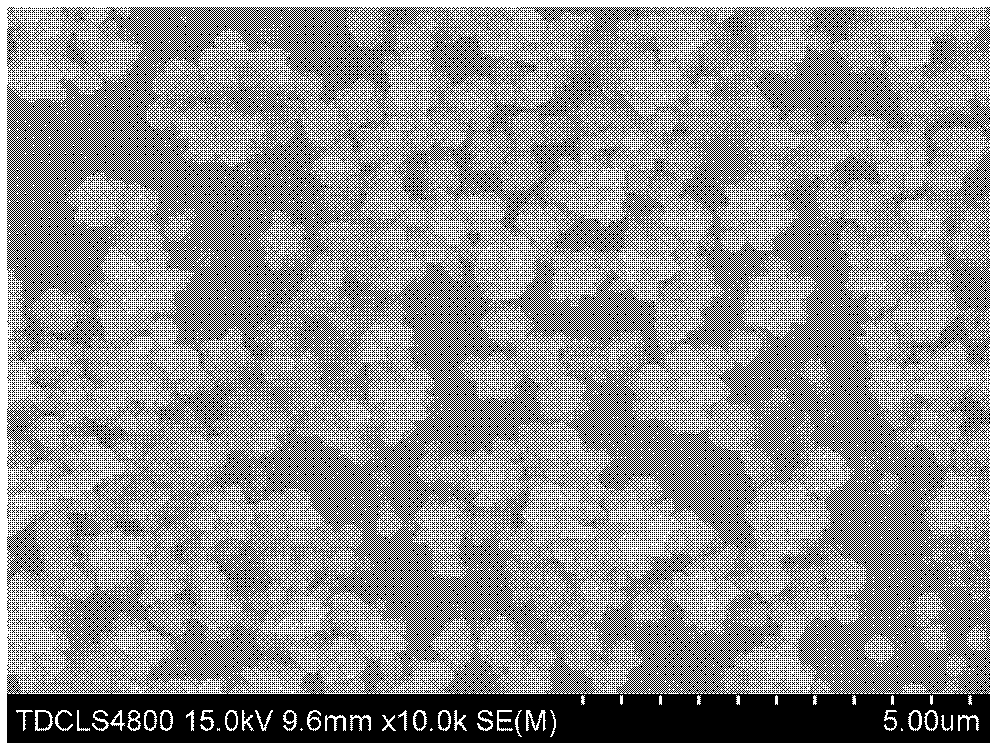

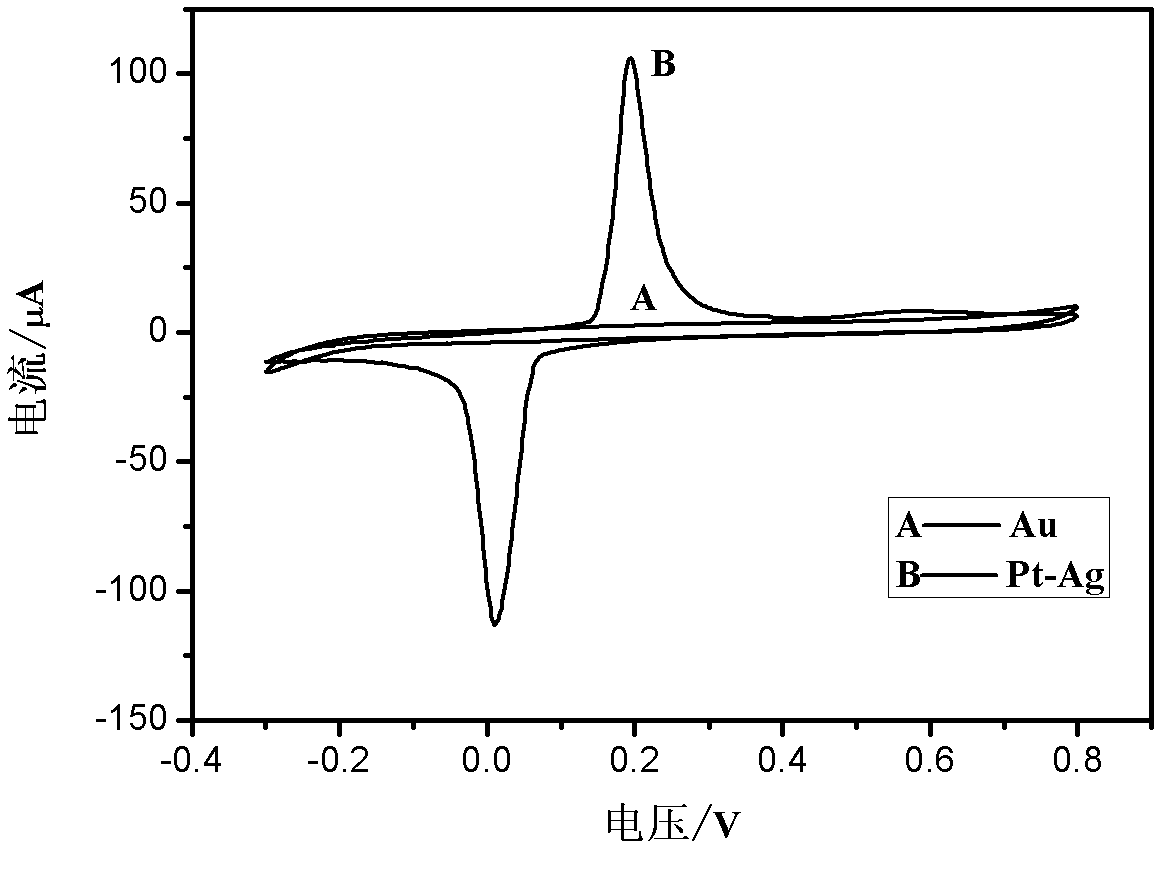

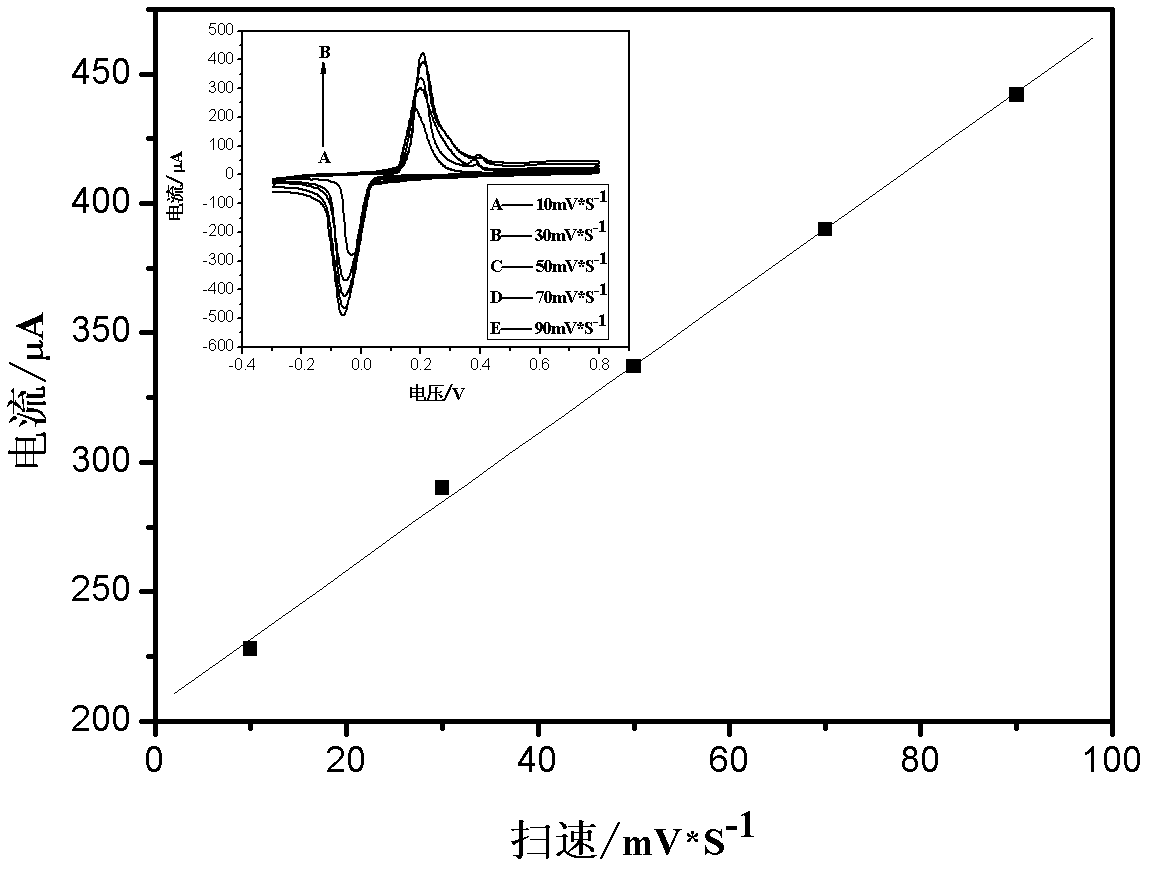

[0026] 0.04×10 in 0.8ml -3 mol / LAgNO3 and 8ml of 0.1mol / L polyvinylpyrrolidone (PVP) were dissolved in 20ml of distilled water, stirred for 30 minutes, then added to 0.8ml of 1mol / L ascorbic acid (AA), and stirred to fully react. Centrifuge at 10000r / min for 15 minutes, wash with distilled water repeatedly to remove remaining PVP. Dissolve the above-prepared Ag nanoparticles in 0.5 ml of distilled water, take 50 μl and dissolve them in 4.8 ml of 0.1×10 -3 mol / L chloroplatinic acid, reacted at room temperature for 72 hours. The Au electrode was ground and polished on buckskin, rinsed repeatedly with twice distilled water, ultrasonicated for 5 minutes in an ultrasonic cleaner with a power of 100 watts, placed in PBS with a pH of 7.0, and activated by cyclic voltammetry scanning for 10 laps for use. Dissolve 50 mg of chitosan in 100 ml of 0.05 mol / L acetic acid solution to form a 0.4% chitosan solution (CS). After dissolving the Pt-Ag alloy nanoparticles prepared in (2) in 0.5...

Embodiment 2

[0028] 0.7ml of 0.04×10 -3 mol / L AgNO3 and 6ml of 0.1mol / L polyvinylpyrrolidone (PVP) were dissolved in 20ml of distilled water, stirred for 20 minutes, then added into 0.6ml of 1mol / L ascorbic acid (AA), stirred to make it fully react. Centrifuge at a rotational speed of 12000r / min for 10 minutes, and wash with distilled water repeatedly to remove the remaining PVP. Dissolve the above-prepared Ag nanoparticles in 0.5 ml of distilled water, take 50 μl and dissolve them in 3.2 ml of 0.1×10 -3 mol / L chloroplatinic acid, reacted at room temperature for 60 hours. The Au electrode was polished on the chicken skin, rinsed repeatedly with twice distilled water, ultrasonicated in an ultrasonic cleaner with a power of 120 watts for 8 minutes, placed in PBS with a pH of 7.0, and activated by cyclic voltammetry scanning for 12 laps for use. 40 mg of chitosan was dissolved in 80 ml of 0.05 mol / L acetic acid solution to form a 0.5% chitosan solution (CS). After dissolving the Pt-Ag allo...

Embodiment 3

[0030] 0.9ml of 0.04×10 -3 mol / L AgNO3 and 10ml of 0.1mol / L polyvinylpyrrolidone (PVP) were dissolved in 20ml of distilled water, stirred for 40 minutes, then added into 1.0ml of 1mol / L ascorbic acid (AA), and stirred to fully react. Centrifuge at a rotational speed of 15000r / min for 8 minutes, and wash with distilled water repeatedly to remove the remaining PVP. Dissolve the above-prepared Ag nanoparticles in 0.5 ml of distilled water, take 50 μl and dissolve them in 5.4 ml of 0.1×10 -3 mol / L chloroplatinic acid, reacted at room temperature for 80 hours. The Au electrode was ground and polished on buckskin, rinsed repeatedly with double distilled water, ultrasonicated for 10 minutes in an ultrasonic cleaner with a power of 150 watts, placed in PBS with a pH of 7.0, and activated by cyclic voltammetry scanning for 15 cycles for use. 60 mg of chitosan was dissolved in 120 ml of 0.05 mol / L acetic acid solution to form a 0.6% chitosan solution (CS). After dissolving the Pt-Ag ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com