Preparation of ordered mesoporous carbon doped with nitrogen atom and preparation and application in immobilized laccase sensor thereof

An immobilized laccase and nitrogen-doped technology is applied in the field of preparation of immobilized laccase sensors, which can solve the problems of difficult electron transfer between enzymes and electrodes, easy deformation and inactivation, etc., and achieves broad research prospects and good repeatability. and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

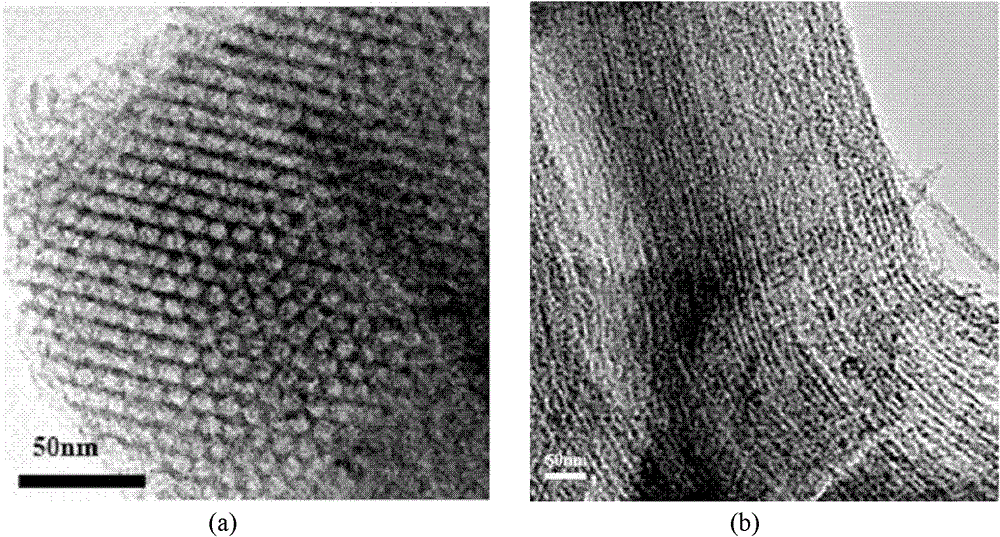

[0029] Add 0.5g of SBA-15 and 2.5g of pure aniline to 500mL of 1M hydrochloric acid with an ammonium persulfate content of 0.6wt.%, stir and dissolve fully, so that the pure aniline is fully dispersed in the mesoporous silicon, and make it in SBA-15 Polymerization occurs in the channels of the aniline, and then vacuum-dried at 100°C for 12 hours; add 3.0 g of ammonium persulfate into 50 mL of 1M hydrochloric acid and stir until it dissolves evenly, then add it to the previously dried mixture to complete the aniline polymerization, and then at 40 °C for 24 hours under vacuum; under the protection of a nitrogen atmosphere with a flow rate of 100mL / min, the mixture prepared above was carbonized at a rate of 5°C / min to 950°C for 6h; finally, the obtained product was treated with 40wt% hydrofluoric Soak in acid overnight to remove the silicon template, then filter, wash with ethanol and deionized water, and dry at 100°C to constant weight to obtain N-OMC. The N-OMC that makes is do...

Embodiment 2

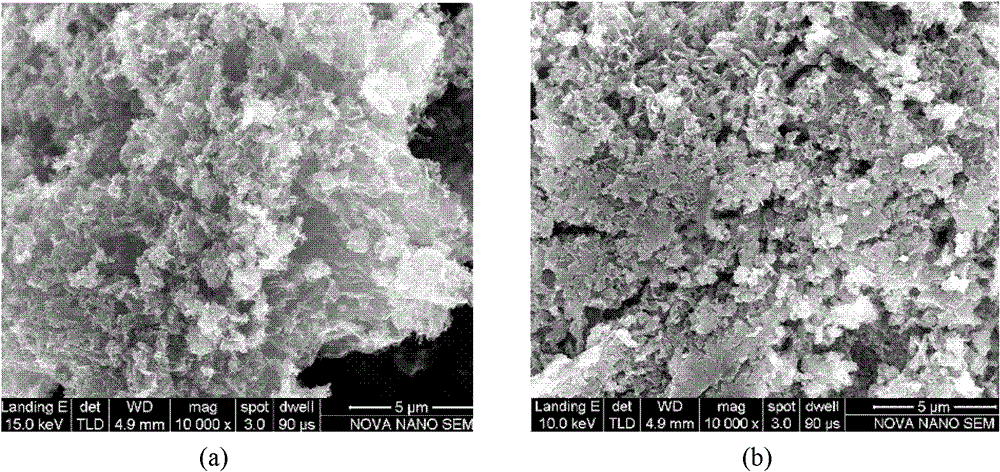

[0031] Add 800mg of N-OMC to 90mL of 98wt% concentrated sulfuric acid and 30mL of 68wt% nitric acid mixed solution, after ultrasonic treatment for 20min, heat and stir in a water bath at 60°C for 1h, and filter with a 0.22μm microporous membrane to remove the acid liquid, washed with deionized water to weak acidity, and finally dried in vacuum at 60 °C to obtain acidified N-OMC. Add 4 mg of acidified N-OMC to 4 mL of the prepared 1.0 mg / mL Lac solution, and stir at 4°C for 24 hours to ensure that the enzyme is fully immobilized on the carrier material, centrifuge, and remove the supernatant. The N-OMC immobilized laccase was obtained. The acidified N-OMC and N-OMC immobilized laccase were analyzed by scanning electron microscope (SEM), as figure 2 As shown, it can be seen that the surface of the acidified N-OMC is very loose before adding the enzyme, but after adding laccase, the surface of the material becomes tighter, which proves that the laccase is loaded in the pores of...

Embodiment 3

[0033] Al with uniform particle size 2 o 3 The Au electrode was ground and polished on suede, rinsed with twice distilled water, ultrasonicated, placed in a PBS solution with a pH of 5.0, and activated by cyclic voltammetry scanning for 10 cycles. Mix the N-OMC-immobilized laccase complex prepared in Example 2 with 4 mL of pre-prepared 0.1% polyvinyl alcohol (PVA) solution to prepare 1.0 mg / ml of Lac+N-OMC / PVA solution, and then use a micropipette to take 10 μL of the mixture to evenly cover the pre-treated Au electrode, and let it stand at room temperature for 2 hours to obtain a Lac+NOMC / PVA / Au electrode.

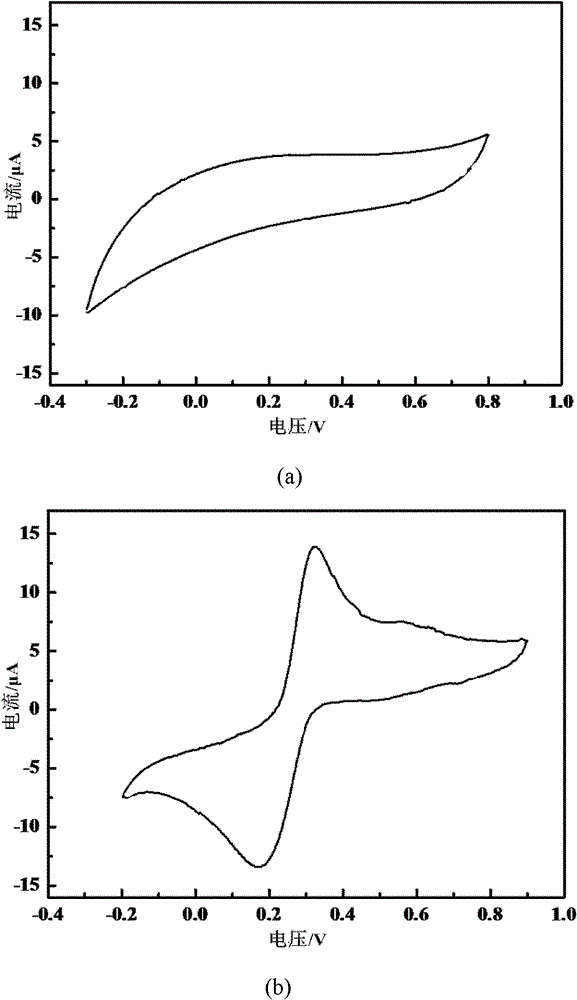

[0034]The CV curve analysis of the prepared N-OMC+Lac / PVA / Au electrode was done in pH=5.0 PBS buffer solution without catechol and with 0.05mM catechol respectively. The electrochemical test adopts a three-electrode test system: platinum (Pt) wire (1mm in diameter) is used as a counter electrode, a saturated calomel electrode is used as a reference electrode, and an N-O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com