Patents

Literature

41results about How to "Broad research prospects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

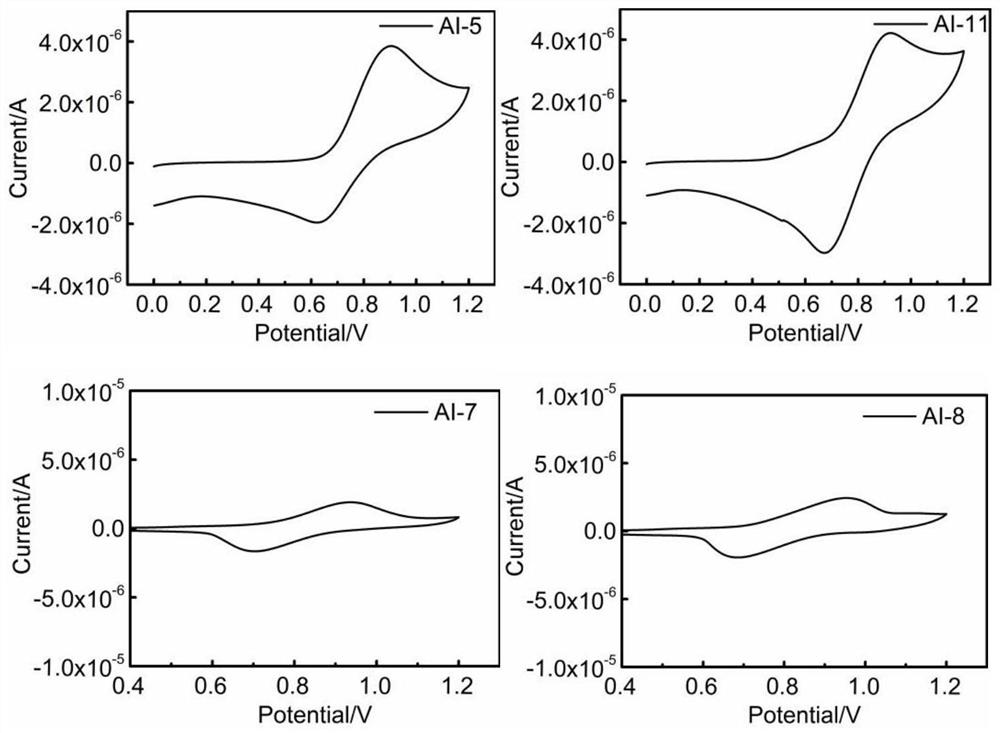

Preparation of ordered mesoporous carbon doped with nitrogen atom and preparation and application in immobilized laccase sensor thereof

ActiveCN102320589AGood direct electrochemical behaviorImprove Sensing PerformanceMaterial electrochemical variablesAnilineNitrogen gas

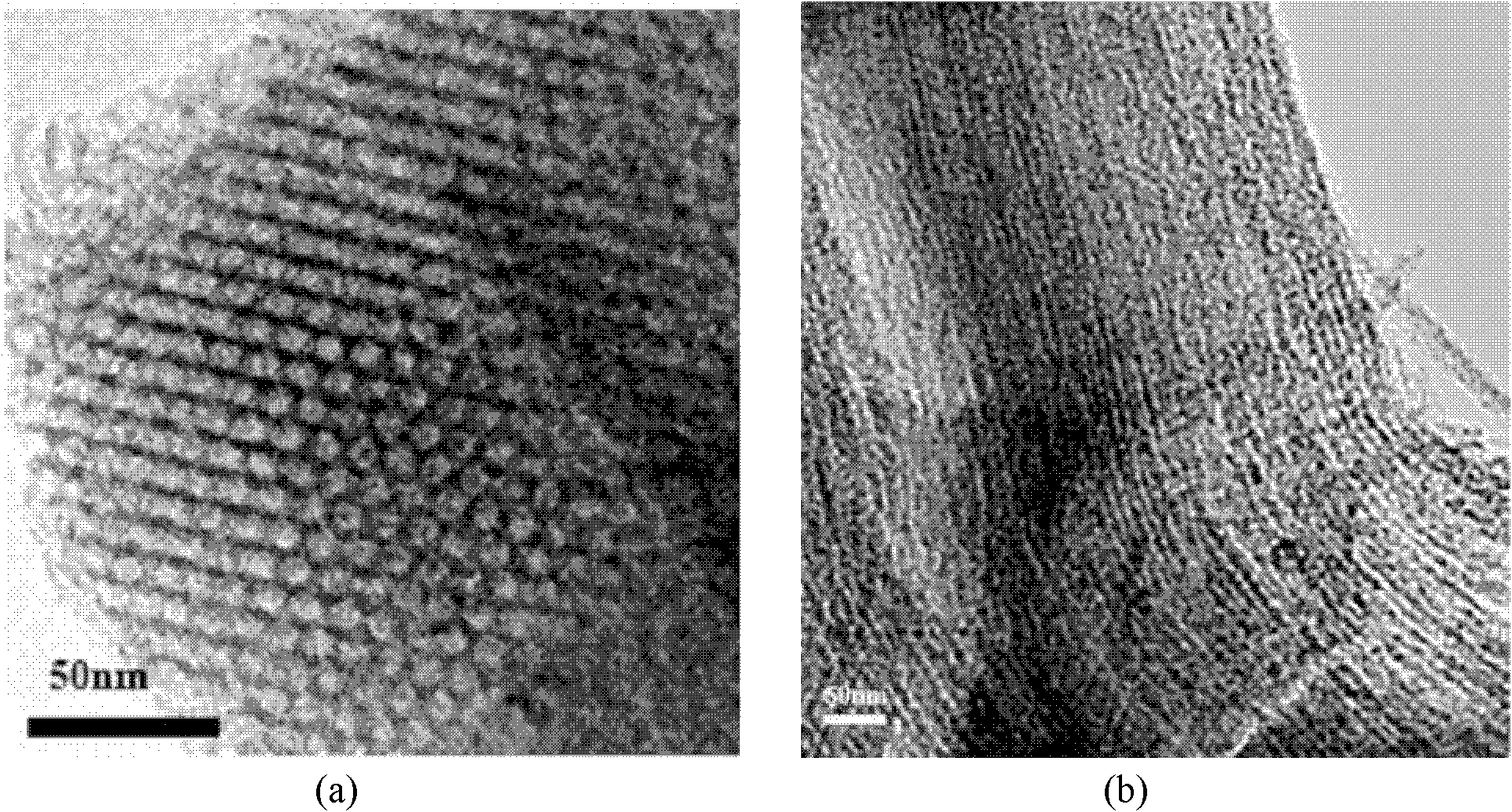

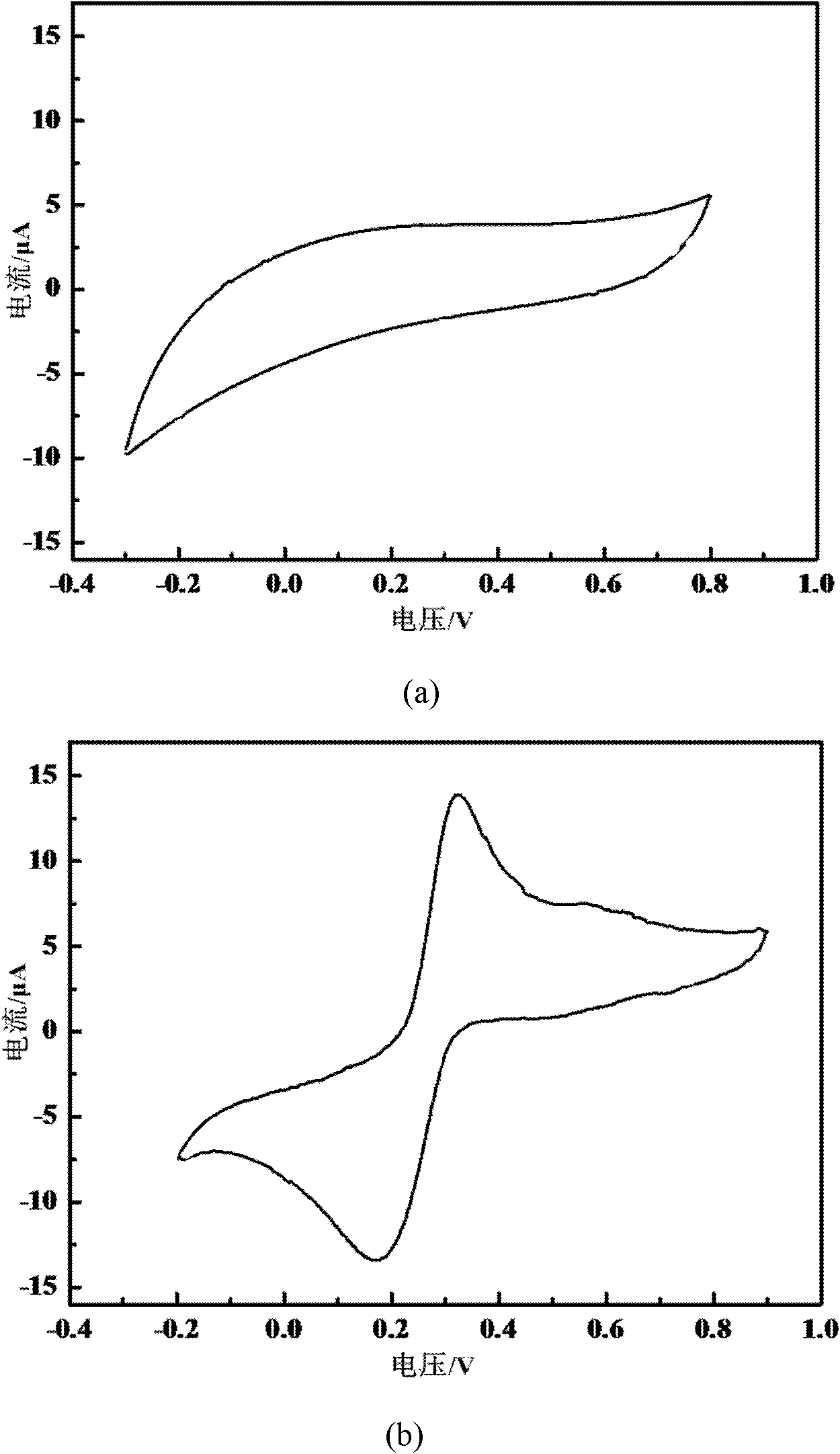

The invention relates to preparation of ordered mesoporous carbon doped with nitrogen atoms and preparation and an application in an immobilized laccase sensor thereof. SBA-15 and pure aniline are dissolved in hydrochloric acid with dissolved ammonium persulfate, and vacuum drying is performed; ammonium persulfate is dissolved in hydrochloric acid, and is added into the dried mixture, and vacuum drying is performed; the prepared mixture is carbonized with the protection of nitrogen atmosphere; the obtained product is soaked with 40 wt% hydrofluoric acid, filtered, washed, and dried to obtain a constant weight. The preparation of an N-OMC modified gold electrode comprises the following steps: buffing and polishing an Au electrode, flushing with distilled water, performing ultrasonic cleaning, performing activation for 10 cycles by cyclic voltammetry scan in a PBS solution with a pH of 5.0, adding the acidified N-OMC into a prepared 1.0-2.0 mg / mL laccase solution, stirring, performing centrifugation separation, and removing the supernatant. The N-OMC modified immobilized laccase gold electrode has good electrocatalytic activity, a wide linear response range, and high sensitivity and selectivity for catechol.

Owner:JIANGSU XINYUEHUA ENERGY SAVING GLASS TECH CO LTD

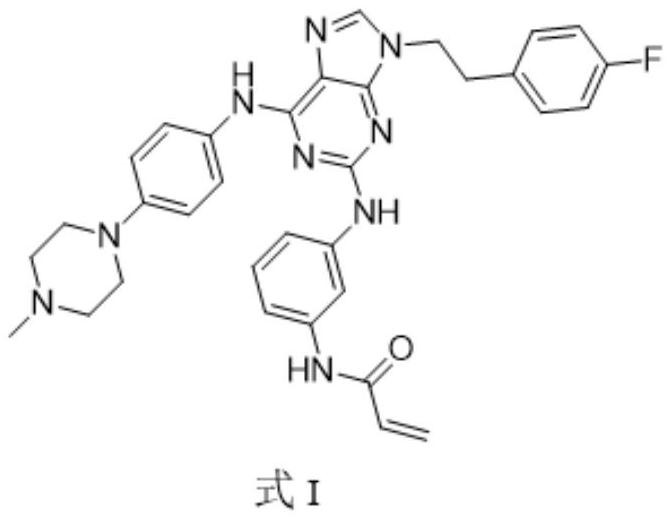

D-type graphite cast iron containing lead, arsenic and tin

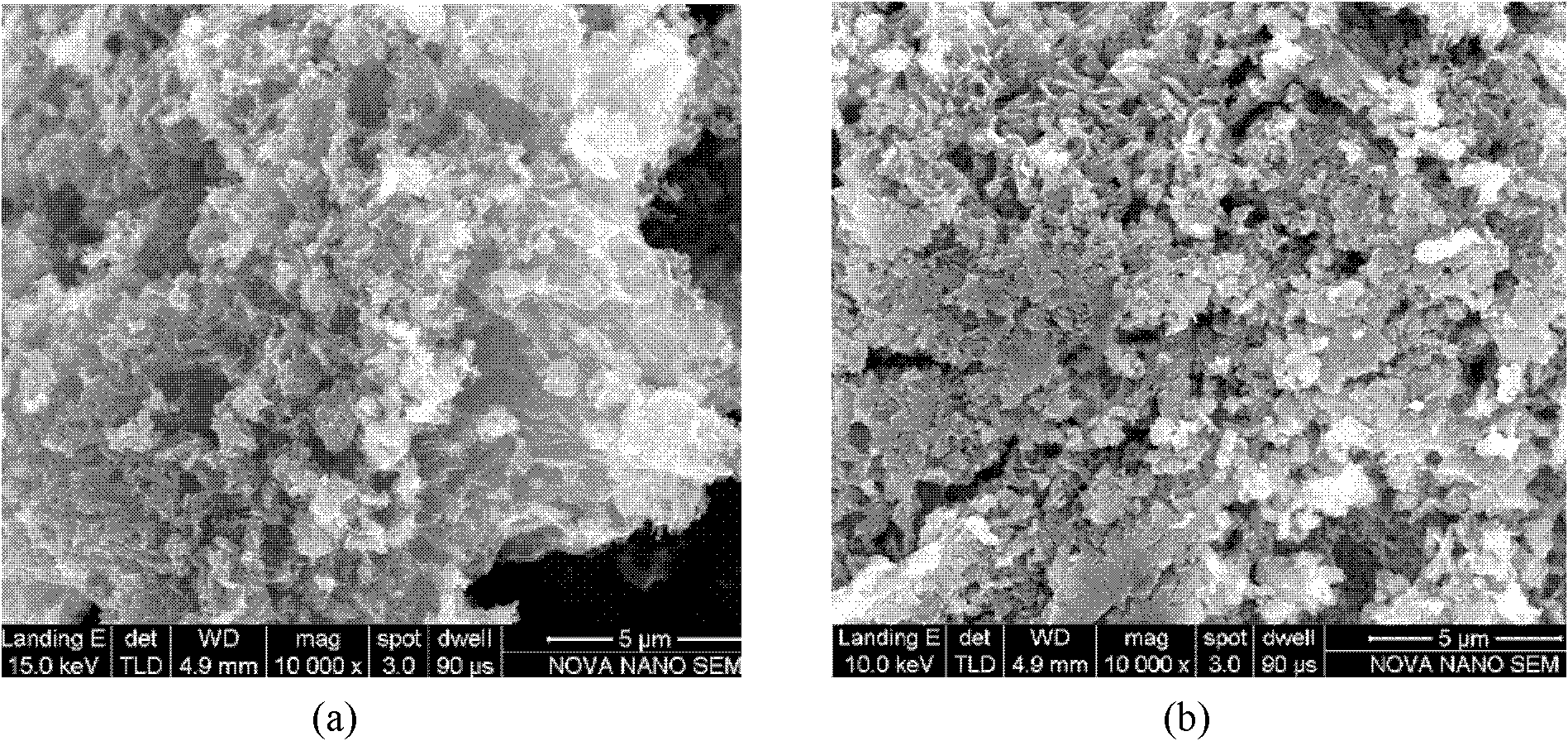

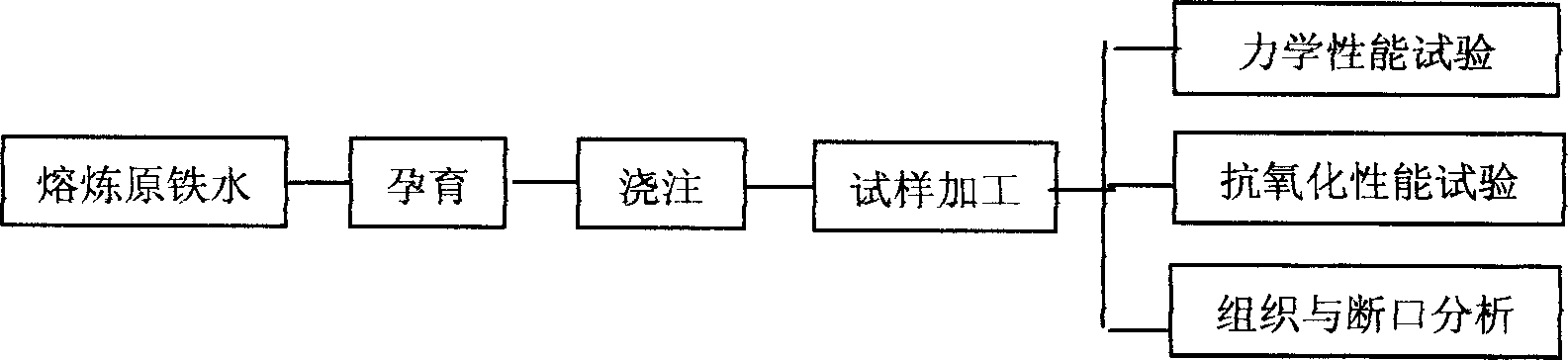

The present invention is one kind of type-D cast iron containing Pb, As and Sn and with raised performance. The present invention is superior to available technology, in which Pb, As and Sn are harmful to the performance of cast iron. The type-D cast iron of the present invention contains: C 3.9-4.5 (in weight portions, the same below), Si 1.2-1.6, Mn 0.6-0.95, P not more than 0.07, S not more than 0.04, Pb 0.005-0.009, As 0.03-0.08, Sn 0.1-0.4, Al 0.01-0.02 and Ti 0.04-0.09, except Fe. The type-D cast iron of the present invention as one new low cost engineering material has very high strength performance and excellent antioxidant performance, and may be used in high strength parts, such as crank shaft and cam shaft in refrigerator and compressor, heat resisting parts, such as glass mold, and heat resisting and wear resisting casting, such as roller.

Owner:FUZHOU UNIV

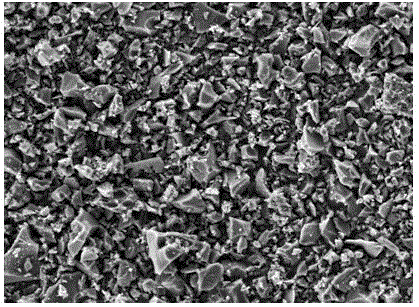

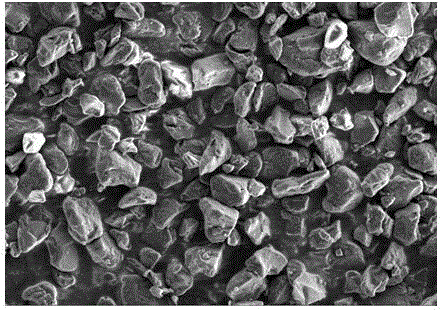

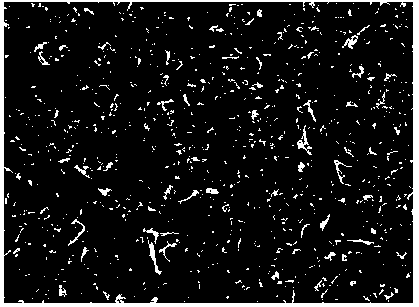

Hard carbon negative electrode material for high-performance lithium ion power battery, and preparation method and application of hard carbon negative electrode material

ActiveCN105355867AEasy to prepareModerate and controllable conditionsCell electrodesSecondary cellsLithiumPower battery

The invention discloses a hard carbon negative electrode material for a high-performance lithium ion power battery, and a preparation method and application of the hard carbon negative electrode material, belonging to the field of electrochemistry. The hard carbon negative electrode material disclosed by the invention is doped with phosphorus, the mass ratio of a phosphorus precursor to a hard carbon precursor is (8-11):6, the hard carbon precursor is phenolic resin, the phosphorus precursor is phosphoric acid, and the particle size of the hard carbon negative electrode material ranges from 10 to 50 micrometers. The rate performance of the hard carbon negative electrode material disclosed by the invention is obviously improved, and the hard carbon negative electrode material has wide research prospect in the field of actual application of the power battery.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

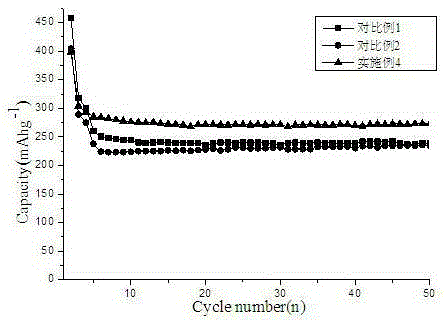

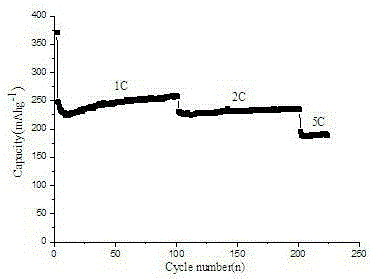

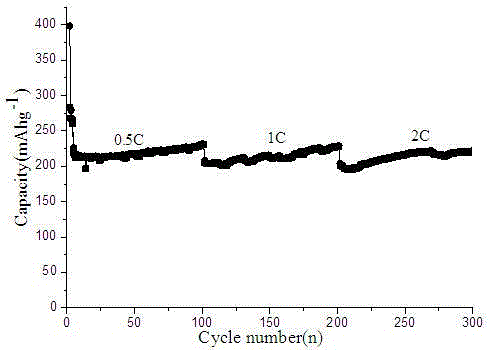

Phenolic resin/coal tar pitch composite-base modified hard carbon negative electrode material and preparation method and application thereof

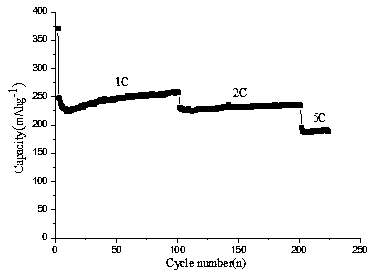

InactiveCN105293467AEasy to prepareModerate and controllable conditionsCell electrodesSecondary cellsMass ratioPhosphoric acid

The invention discloses a phenolic resin / coal tar pitch composite-base modified hard carbon negative electrode material and a preparation method and application thereof, and belongs to the field of electrochemistry. According to the phenolic resin / coal tar pitch composite-base modified hard carbon negative electrode material, phenolic resin and coal tar pitch serve as hard carbon precursors, and the mass ratio of the phenolic resin to the coal tar pitch is 2:1-4. The phenolic resin is modified through phosphoric acid, and the mass ratio of the phosphoric acid to the phenolic resin is 1-5:10. The particle size range of the hard carbon negative electrode material is 10-50 microns. The primary coulombic efficiency of the negative electrode material under the 0.5 C multiplying power is 80.55%, under the 2 C multiplying power, the volume is kept to be about 221 mAh / g after recycling is conducted 300 times, the volume does not greatly differ from the volume under the 0.5 C multiplying power and the 1 C multiplying power, and it shows that good volume maintaining performance and coulombic efficiency are achieved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

Method for leaching lithium form coal ash

ActiveCN107130119AImprove refined utilization valueAvoid pollutionProcess efficiency improvementMuffle furnaceGrinding mill

The invention discloses a method for leaching lithium form coal ash. The method includes the steps of 1), a sintering process, namely weighing the coal ash, sodium carbonate and calcium carbonate in the mass ratio of 1:0:1-1:0:0.8:1, performing even mixing in a corundum crucible, placing the mixture in a muffle furnace for roasting for 60-100 minutes at the temperature ranging from 1000DEG C to 1200DEG C, cooling to indoor temperature and grinding the mixture to 200 mesh with a ball grinding mill; 2), a leaching process, namely evenly mixing a well-ground clinker with a sodium carbonate solution 3-8% in concentration in the solid-to-liquid ratio of 1:15-1:25 prior to transferring to a colloid grinder, subjecting the mixture to mechanical grinding for 30 minutes prior to transferring to a high-pressure kettle, cooling mixed liquid in the high-pressure kettle after high-pressure cooking for 20-60 minutes at the temperature ranging from 100DEG C to 150DEG C is completed prior to performing extraction filtration to obtain lithium leaching liquid. The method for leaching the lithium form the desiliconized coal ash through alkali sintering-dilute alkali dissolution is put forward for the first time, broad research prospects for extracting the lithium form the coal ash are achieved, a foundation is laid for research in developing lithium resources and application strategies, and meanwhile, industrial utilization valve of the coal ash is improved.

Owner:HEBEI UNIV OF ENG

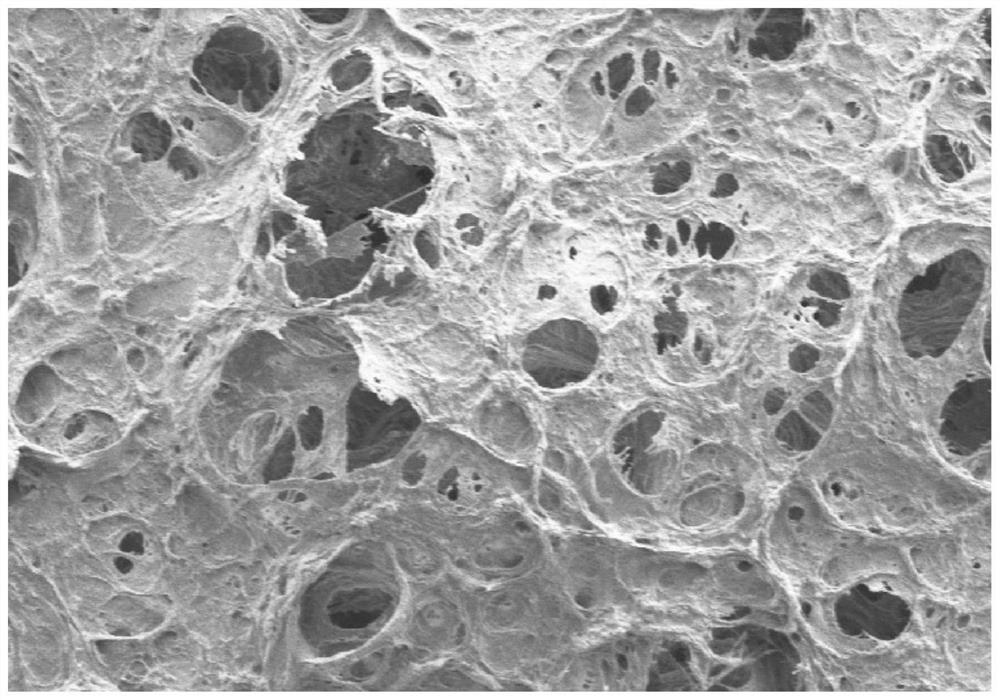

Biochar-based thermosetting resin composite material and preparation method thereof

The invention discloses a biochar-based thermosetting resin composite material and a preparation method thereof. The preparation method of the biochar-based thermosetting resin composite material comprises the following steps: (1) pre-treating a biochar raw material, specifically directly taking crushed biochar powder; (2) uniformly mixing the crushed biochar powder with thermosetting resin (one or more selected from epoxy resin, phenolic resin, amino resin, urea resin, unsaturated polyester resin and the like), a curing agent and the like; (3) carrying out filling; and (4) carrying out curingand forming. The preparation method of the biochar-based thermosetting resin composite material is simple in process and is environmentally friendly, the prepared biochar-based thermosetting resin composite material is high in mechanical performance, and high-value comprehensive utilization of renewable biomass resources is achieved.

Owner:BEIJING INST OF TECH ZHUHAI CAMPUS

Environment-friendly high-strength lignocellulose plate and preparing method thereof

InactiveCN105856379AHigh mechanical strengthHigh activityDomestic articlesFlat articlesCellulose fiberHigh intensity

The invention discloses an environment-friendly high-strength lignocellulose plate and a preparing method thereof. The preparing method of the environment-friendly high-strength lignocellulose plate comprises the following steps that firstly, plant raw material pretreatment is conducted, lignocellulose powder with the size smaller than 40 meshes is directly taken, or, plant raw materials rich in lignocellulose fiber are utilized for conducting flash explosion treatment, and the lignocellulose fiber is obtained, wherein the size of the plant raw materials rich in lignocellulose fiber ranges from 2 meshes to 80 meshes; secondly, the lignocelluloses fiber is mixed with a bonding agent, and the bonding agent is PVA and / or gelatin; thirdly, paving is conducted; fourthly, hot pressing is conducted; and fifthly, cooling forming is conducted. The preparing method of the environment-friendly high-strength lignocellulose plate is simple in process, usage of reagents such as acid and alkali is avoided in the whole process, pollution is avoided, and environment friendliness is achieved. The prepared environment-friendly high-strength lignocellulose plate is high in mechanical strength, and pollution-free and high-valued comprehensive utilization of renewable resources is achieved.

Owner:SOUTH CHINA UNIV OF TECH

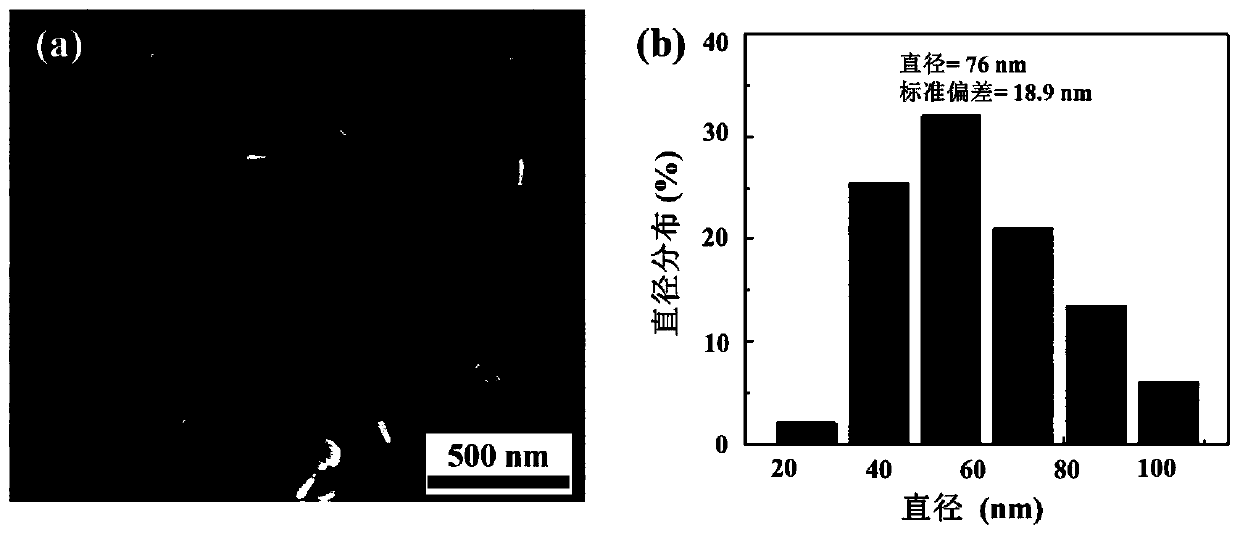

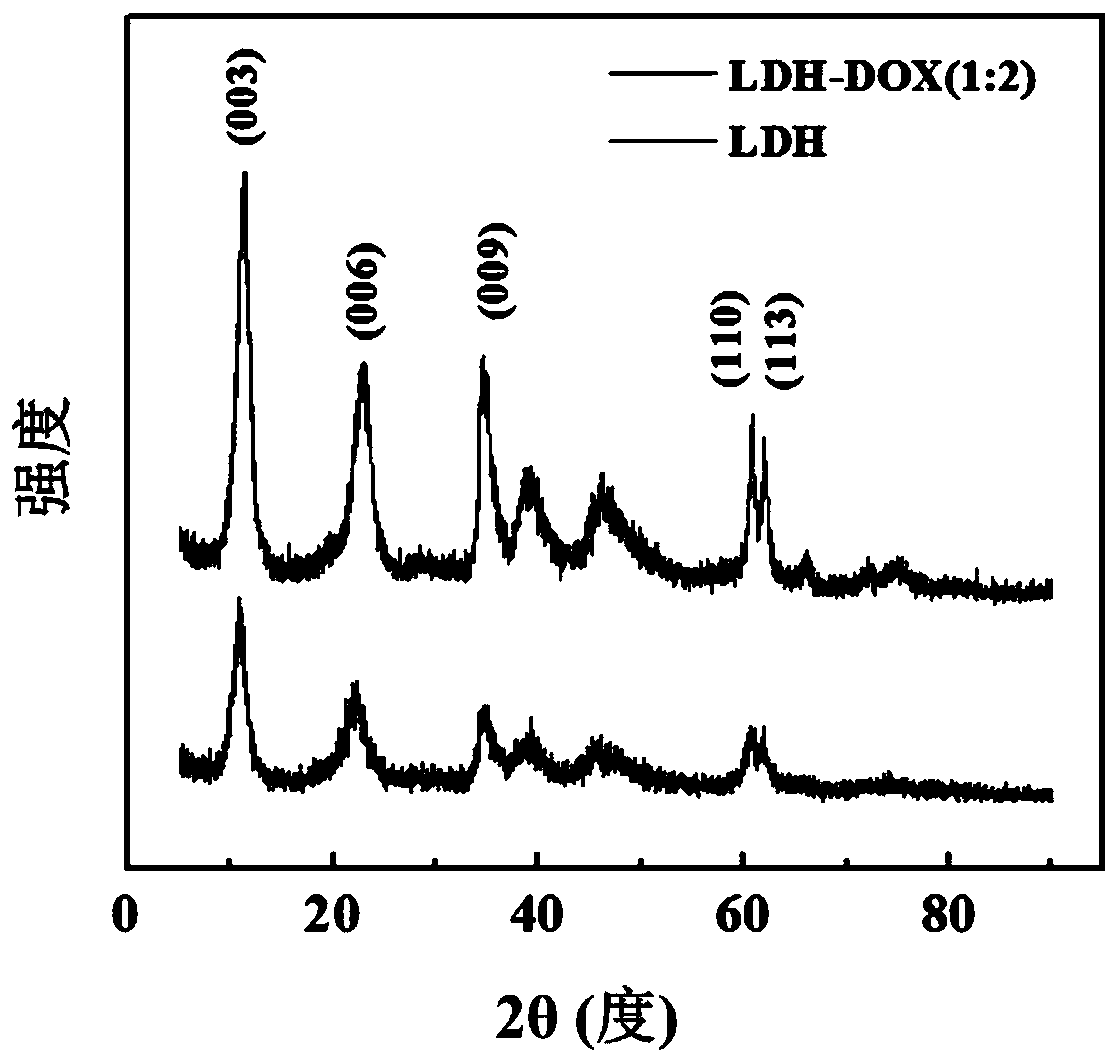

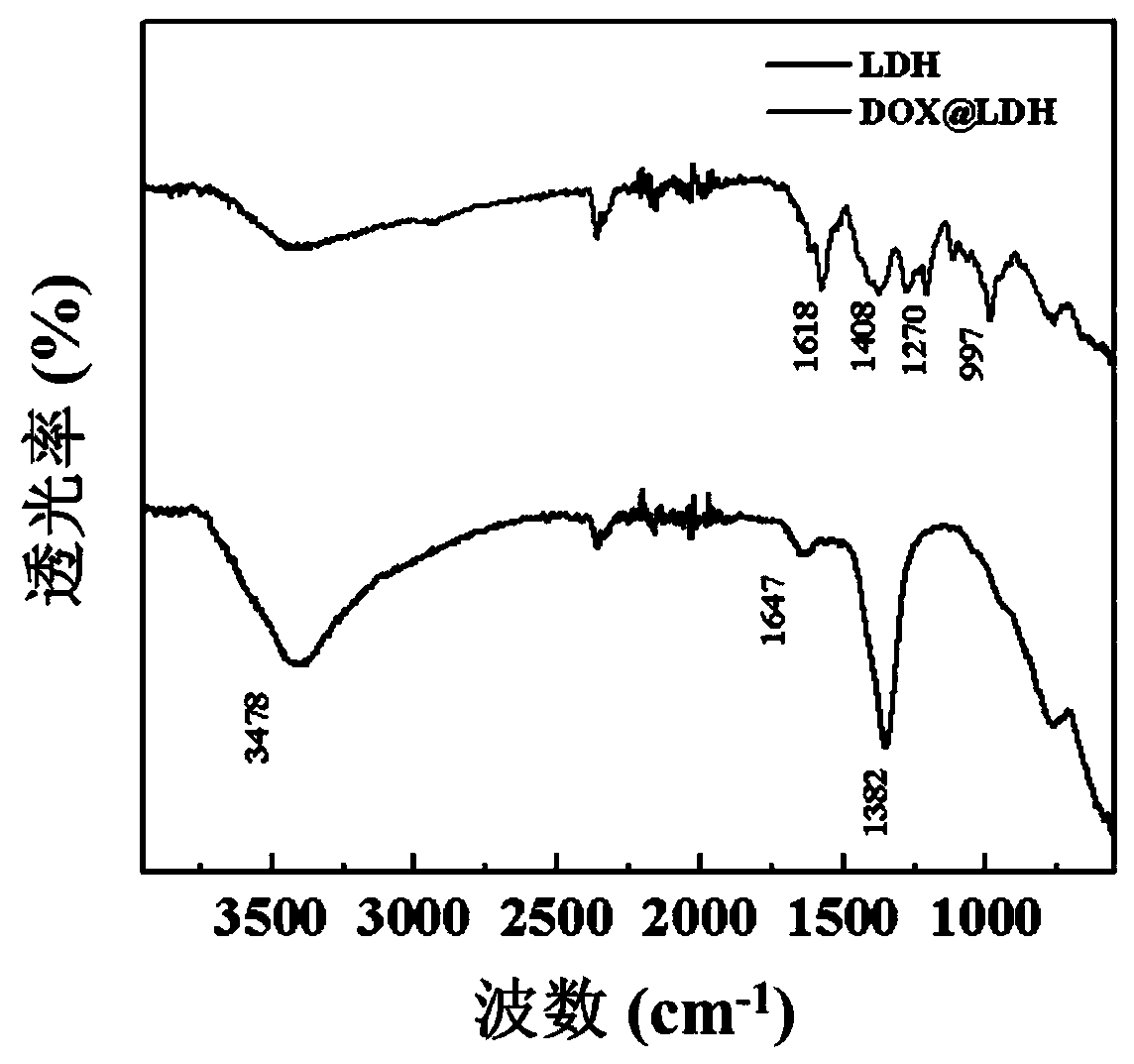

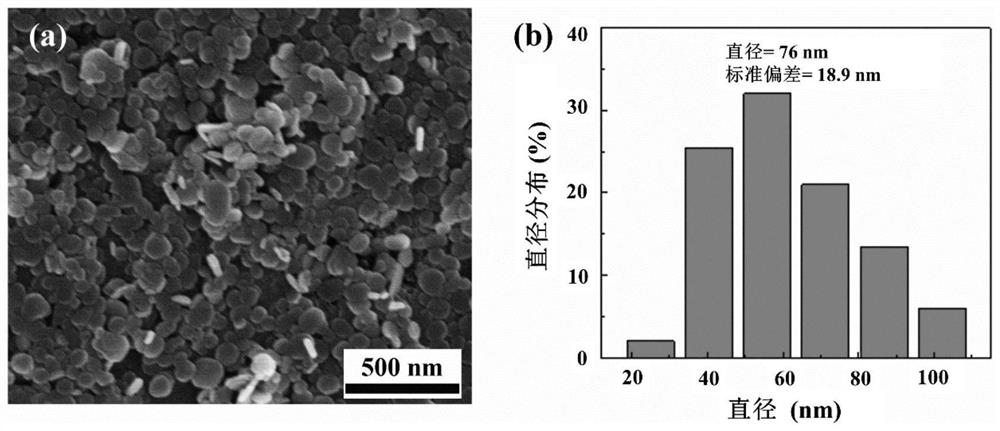

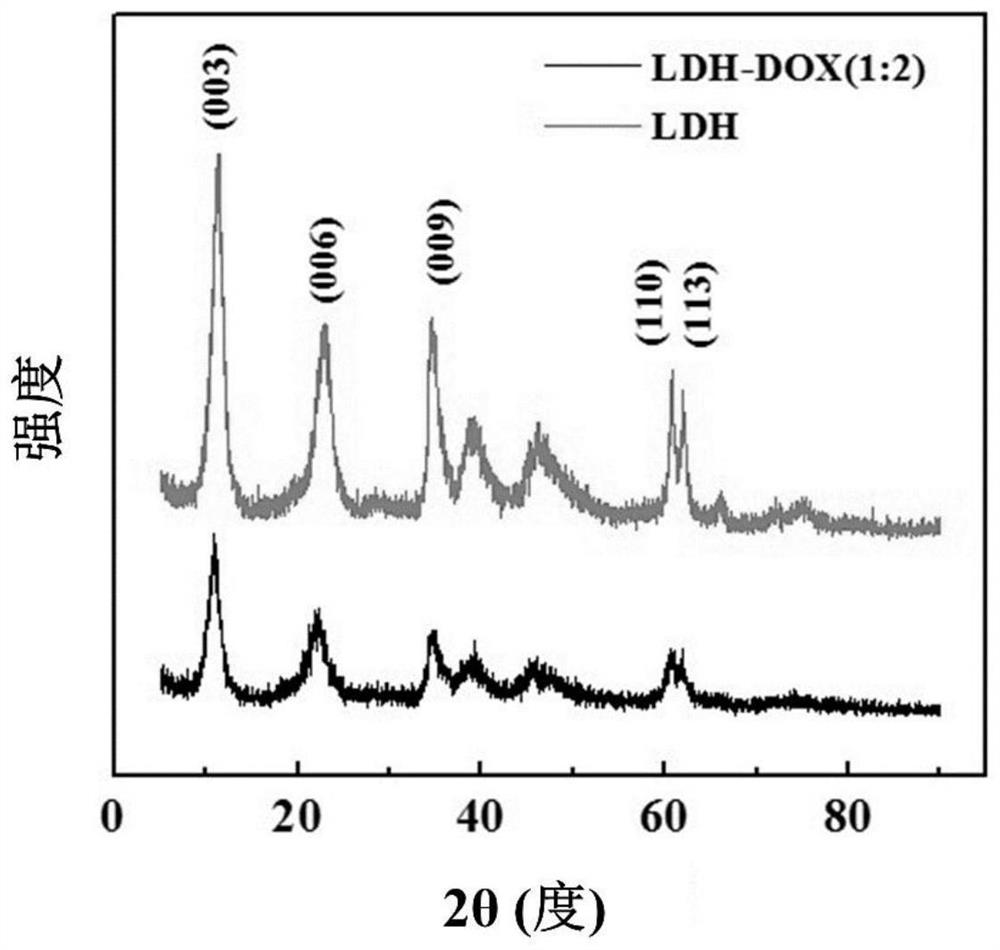

Preparation method of multilevel slow-release drug-loaded short nano-fibers

ActiveCN110201176AGrowth inhibitionOvercoming the problem of multidrug resistanceOrganic active ingredientsInorganic non-active ingredientsFiberCancer cell

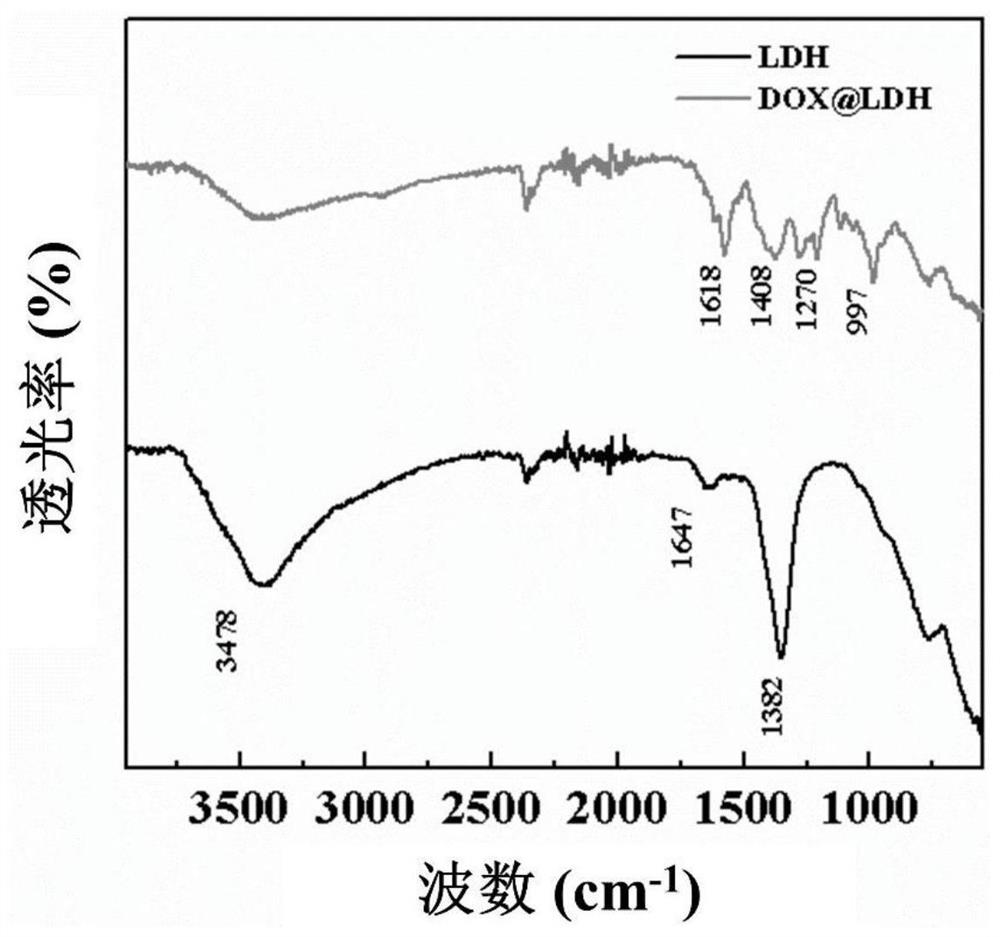

The invention relates to a preparation method of multilevel slow-release drug-loaded short nano-fibers. According to the method, layered double hydroxides (LDH) loaded doxorubicin (DOX) serving as ananti-cancer drug and alpha-tocopherol succinate (alpha-TOS) serving as a P-gp inhibitor are mixed into polylactic acid-glycolic acid copolymer (PLGA) spinning solution, and electrostatic spinning andhomogeneous treatment are implemented to obtain the fibers. The multilevel slow-release double medicine carrying short nano-fibers are built by the aid of organic and inorganic double carriers, multilevel release of the anti-cancer drug and the P-gp inhibitor in materials can be achieved in tumor micro-acidic environments, multi-drug resistance of cancer cells is overcome, the double-carrier nano-fibers lengthen release paths of the drugs, slow release of the anti-cancer drug is achieved, and a novel method is provided for long-term and effective treatment of drug-resistant tumors.

Owner:DONGHUA UNIV

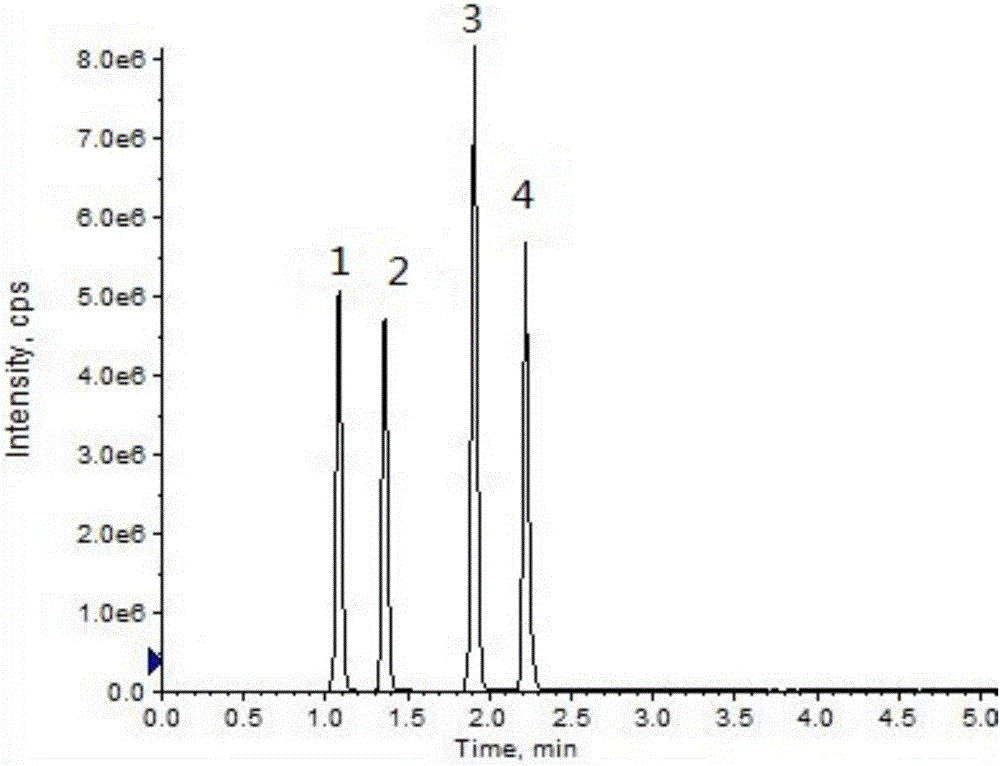

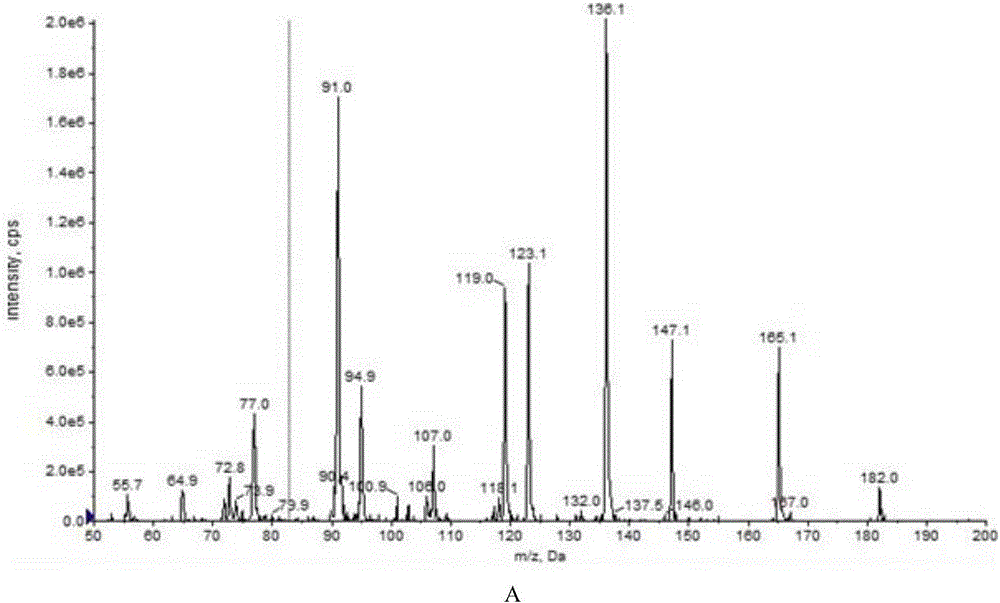

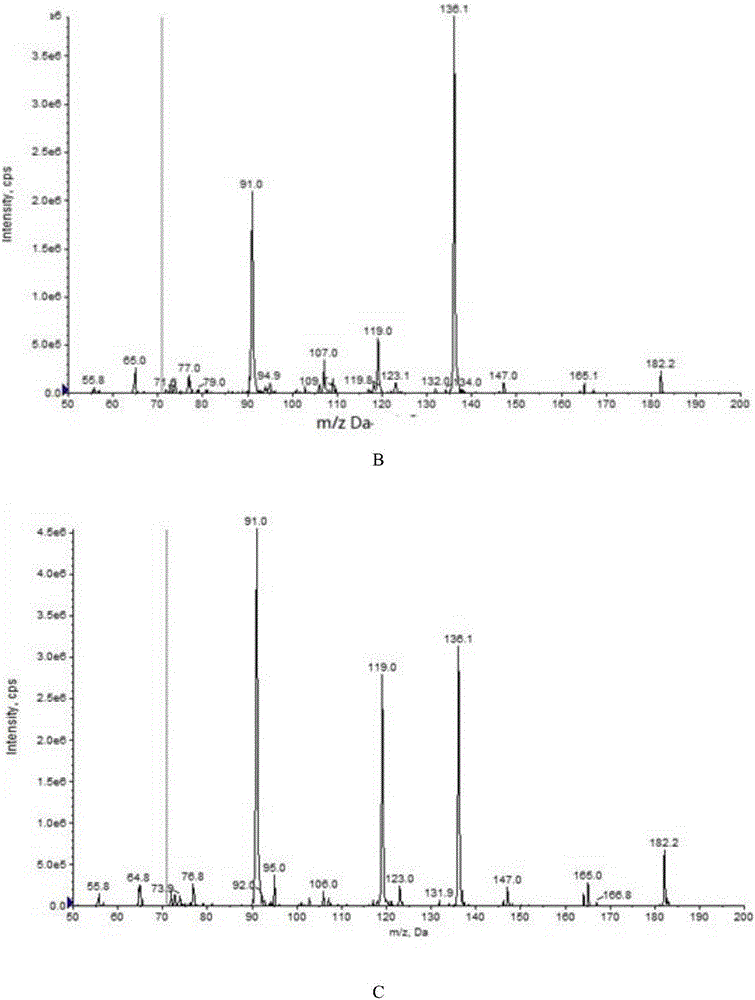

Detection method of irradiated dried seafood

ActiveCN106568870AImprove extraction efficiencyEasy to separateComponent separationQualitative analysisIrradiation

The invention discloses a detection method of irradiated dried seafood, comprising a sample pretreatment step, a QTRAP-UPLC-MS / MS detection analysis step, and an irradiation dose quantitative detection step. A variety of amino acids and isomers thereof can be separated at the same time, and a qualitative analysis, a quantitative analysis, and a secondary qualitative analysis can be made. The method can be used to judge whether dried seafood is irradiated or not and determine the irradiation dose. The result is reliable. The limit of detection is low. The method is suitable for rapid detection of irradiated dried seafood.

Owner:舟山出入境检验检疫局综合技术服务中心

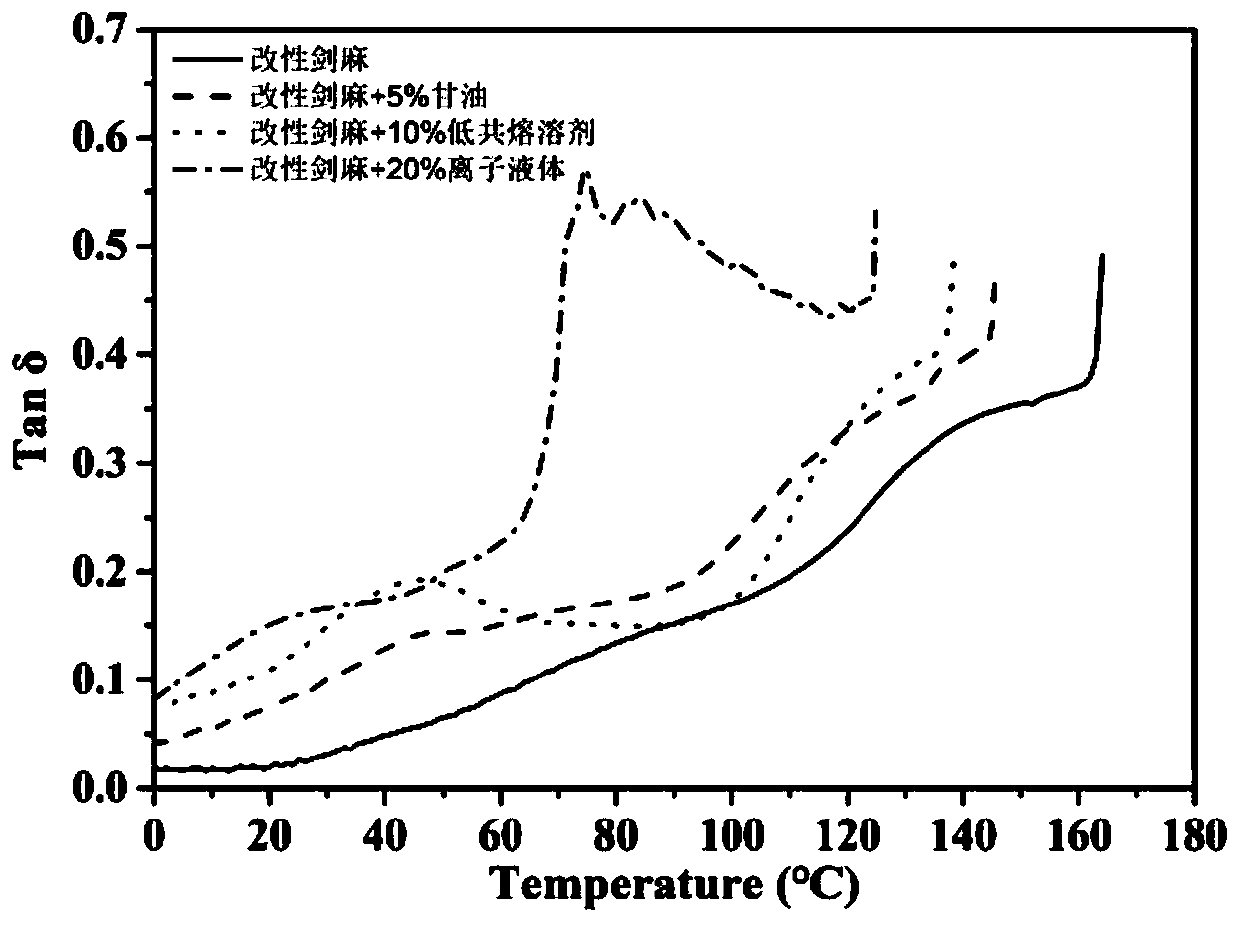

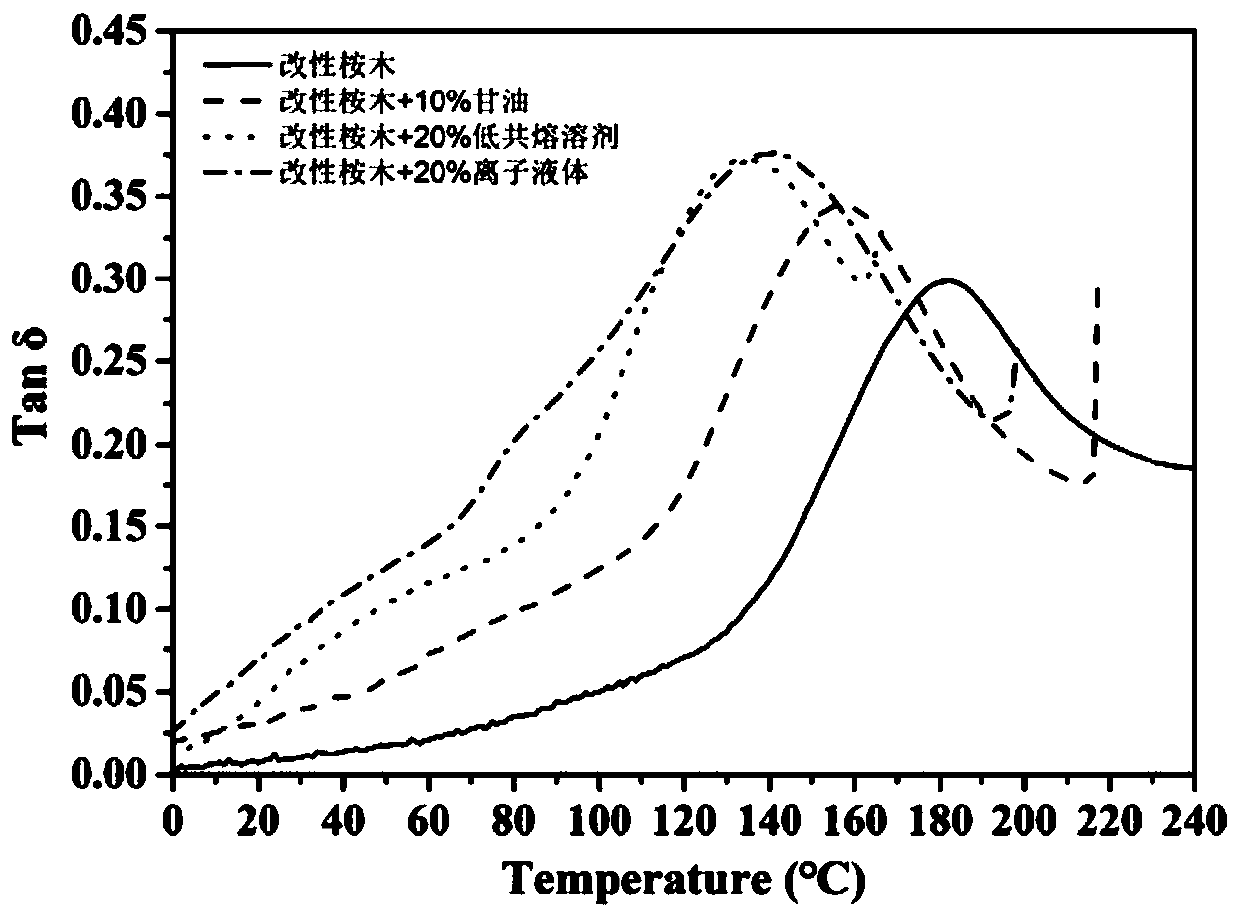

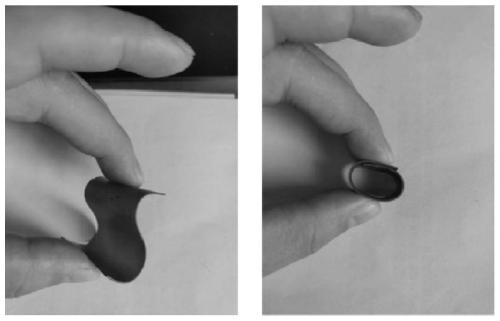

Method for regulating thermoplasticity and toughness of redox-modified plant fiber and application of redox-modified plant fiber

InactiveCN109721770AImprove thermoplasticityImprove toughnessFibrous raw materialsVegetal fibresFiberFiltration

The invention relates to a method for regulating the thermoplasticity and toughness of redox-modified plant fiber. The method comprises the following steps: (1) performing pretreatment on plant fiber;(2) adding an oxidizing agent solution for a reaction, performing filtration and washing so as to obtain oxidization-modified plant fiber, adding a reducing agent solution for a reaction, and performing filtration and washing so as to obtain redox-modified plant fiber; and (3) adding a plasticizer, and mixing the plasticizer with the redox-modified plant fiber uniformly, wherein the plasticizer is a hydroxy plasticizer, an ionic liquid plasticizer, an eutectic solvent plasticizer, an ester plasticizer, an amine plasticizer, a glycidyl ether plasticizer or an inorganic salt plasticizer. Through the method, the flexibility of the redox-modified plant fiber material can be improved, the processing temperature of the plant fiber material can be reduced, and the processing window of the plantfiber material can be widened.

Owner:SOUTH CHINA UNIV OF TECH

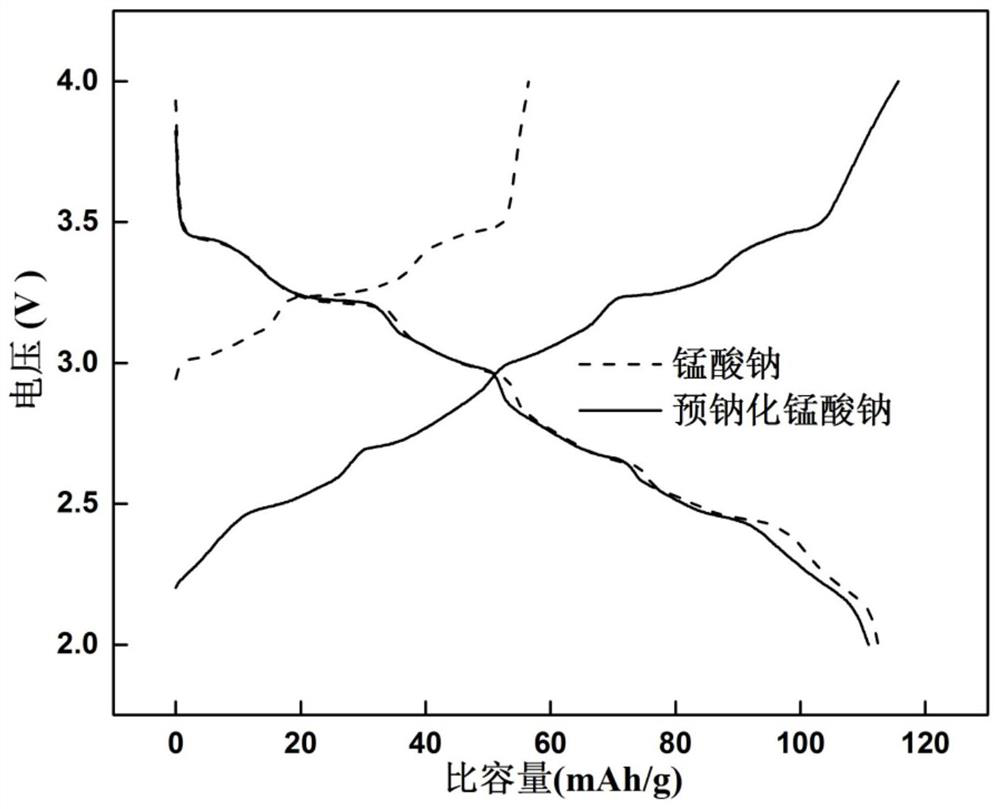

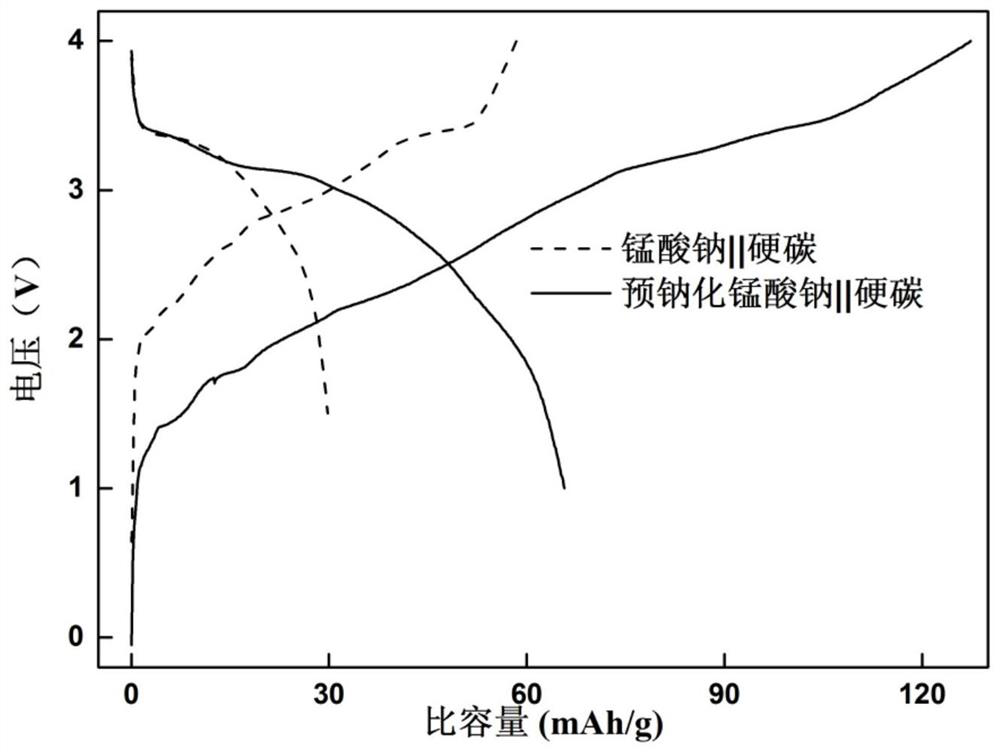

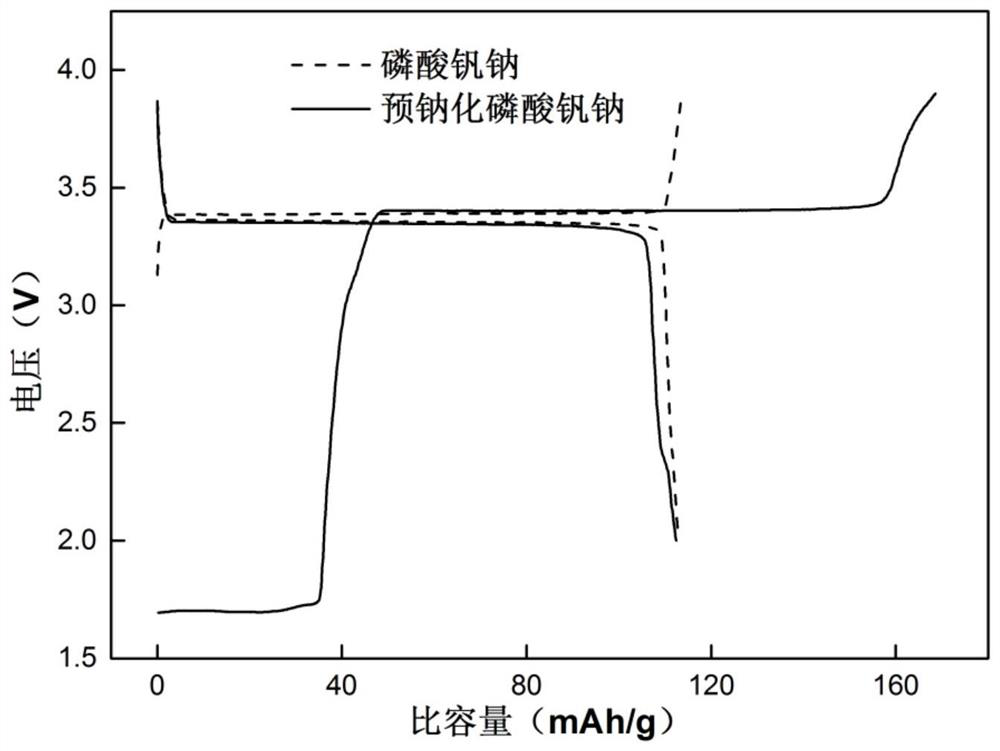

Pre-sodium-modified sodium ion battery positive electrode, and pre-sodium-modified method and application thereof

ActiveCN112952037AIncrease energy densityImprove cycle lifeSecondary cellsPositive electrodesAnthracenePhenanthrene

The invention discloses a pre-sodium-modified sodium ion battery positive electrode material, and a pre-sodium-modified method and application thereof. The method comprises the following step: in an inert atmosphere, reacting a sodium-ion battery positive electrode with an aryl sodium-modification reagent solution to obtain a pre-sodium-modified sodium-ion battery positive electrode wherein the aryl sodium modification reagent is one or more of biphenyl sodium, naphthalene sodium, pyrene sodium, anthracene sodium or phenanthrene sodium. A sodium-rich or over-sodium-rich positive electrode is obtained by reacting the positive electrode of the sodium-ion battery with the solution of the aryl sodium modification reagent, the half-battery first-cycle charge specific capacity is obviously improved and is matched with the efficiency of a negative electrode, the first-cycle discharge specific capacity after the whole battery is prepared reaches the theoretical specific capacity of the positive electrode, and the energy density reaches 300Wh / kg; and the method substantially improves the energy density and the cycle life of the battery, has the advantages of wide research prospect and application value, mild reaction conditions, good safety, good stability of the obtained battery, and industrial popularization and application prospect.

Owner:SHENZHEN JANAENERGY TECH CO LTD

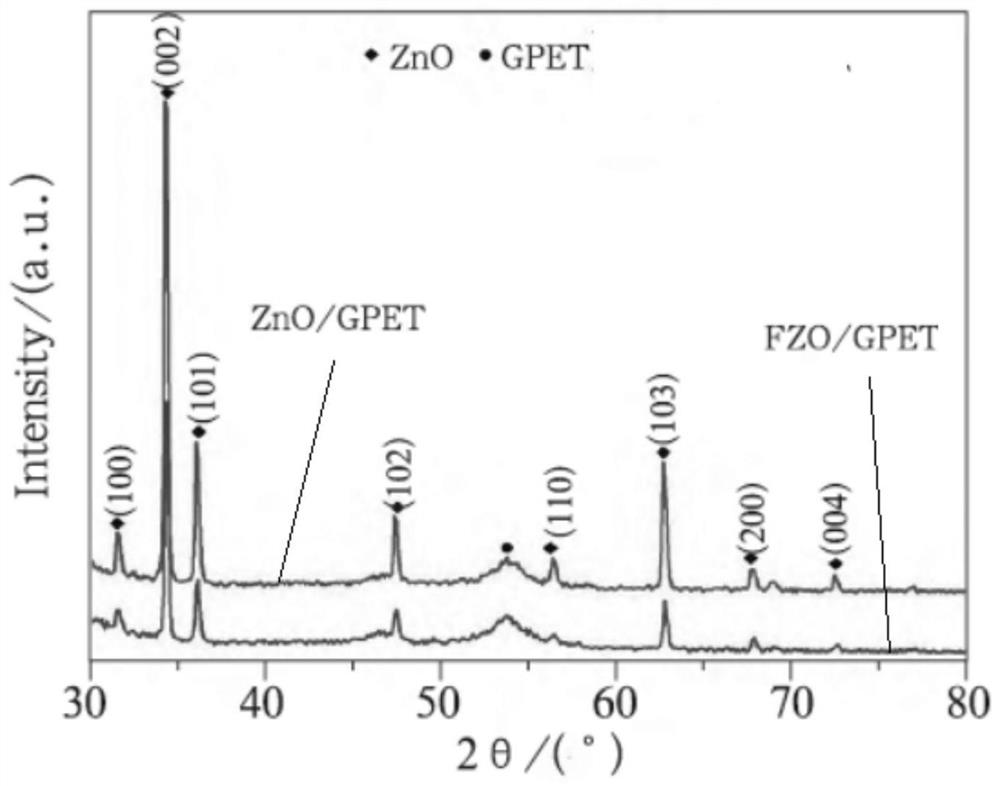

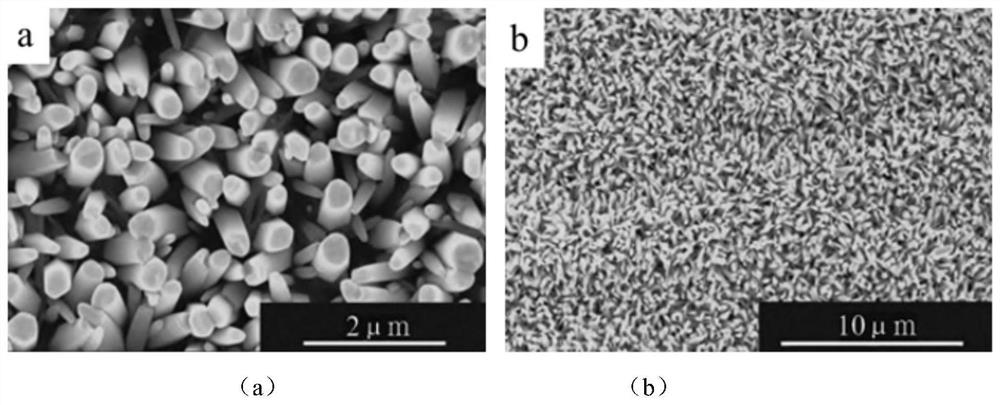

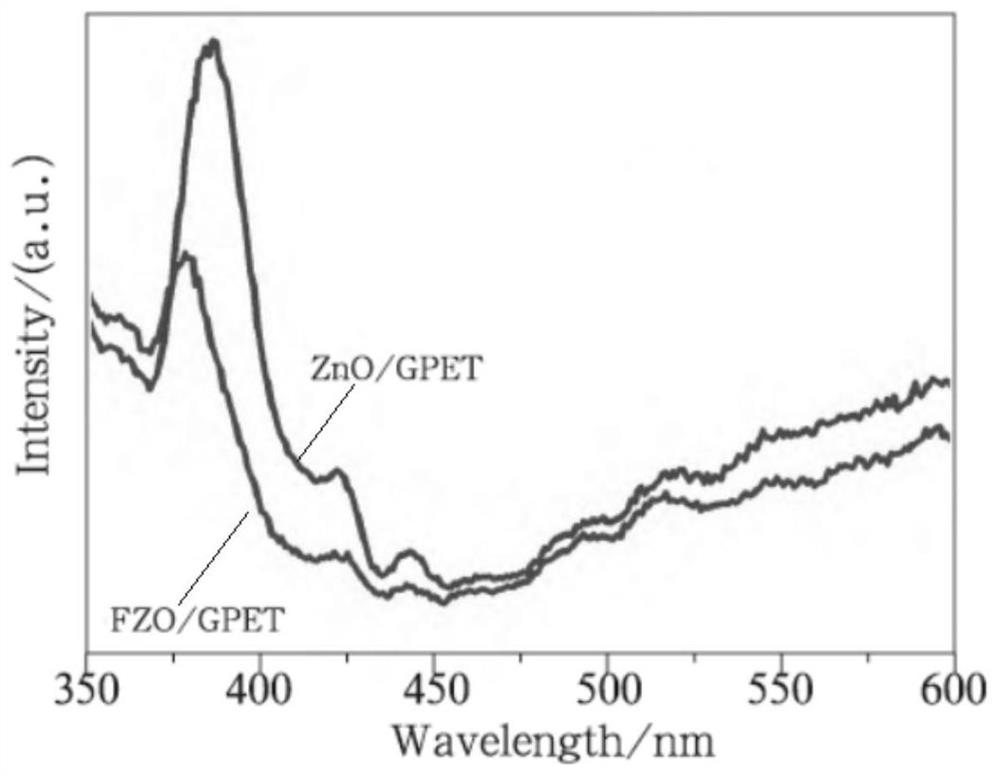

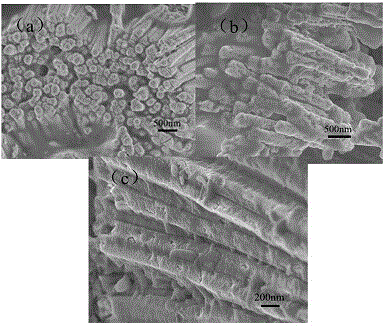

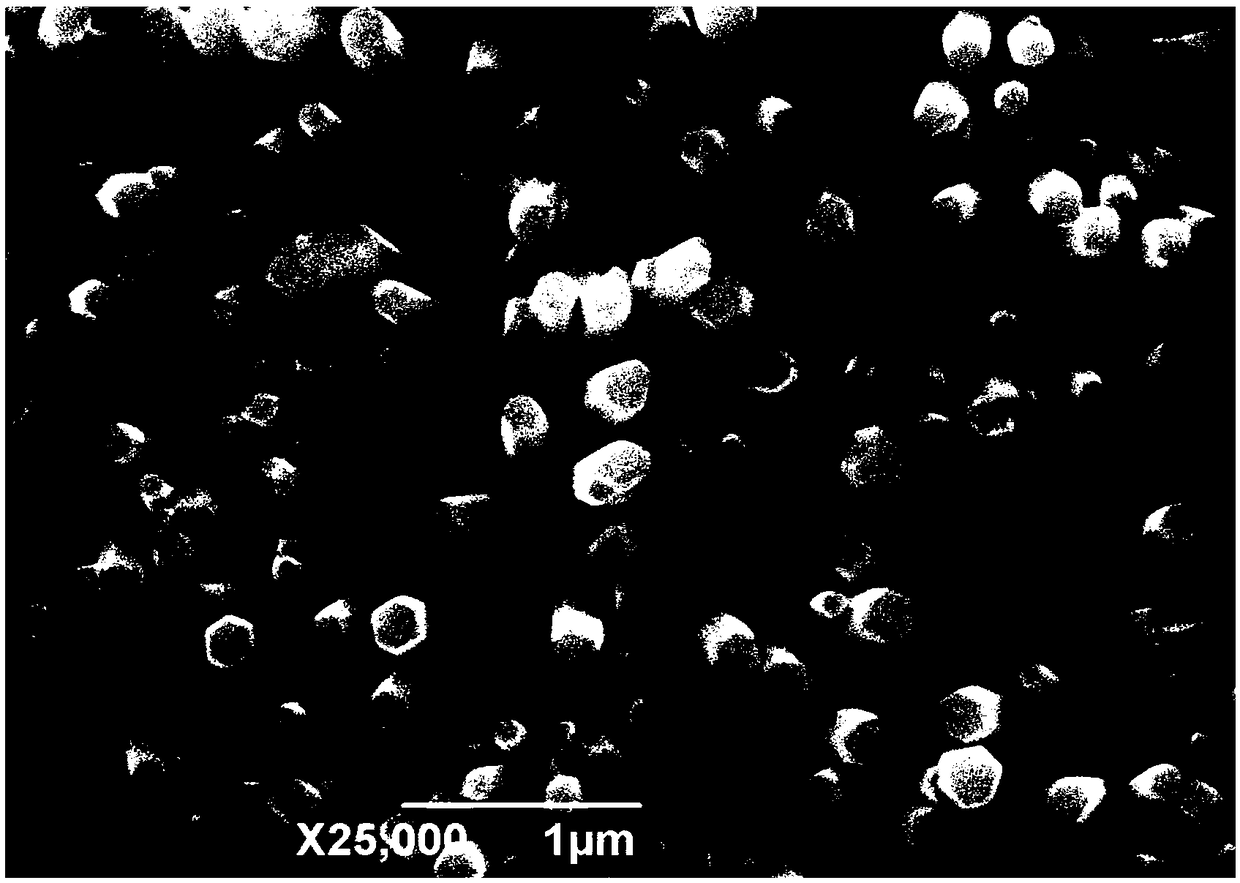

Fe-doped ZnO nano-film as well as preparation method and application thereof

PendingCN112371179AFacilitate hydrothermal growthReduce manufacturing costWater/sewage treatment by irradiationWater treatment compoundsHexamethylenetetramineZinc nitrate

The invention discloses a Fe-doped ZnO nano-film as well as a preparation method and application thereof. A Fe-doped ZnO nano-material is successfully prepared on a GPET transparent conductive flexible substrate through a hydrothermal method, the photocatalytic performance of the Fe-doped ZnO nano-material is researched. Zinc nitrate hexahydrate, hexamethylenetetramine and ferric nitrate nonahydrate are taken as main reactants, firstly ion sputtering is conducted on the surface of a flexible substrate GPET to obtain a very thin ZnO seed crystal layer; then Fe-doped ZnO precursor solutions withdifferent concentrations are prepared; and the flexible substrate is vertically put in a reaction solution, and a Fe-doped ZnO nano structure is grown by a hydrothermal method to obtain the Fe-ZnO / GPET nano composite material which can be used as a photocatalyst. The product obtained through the hydrothermal reaction has a special regular hexagonal nanorod-like structure, has a strong degradationeffect on a methylene blue solution, has a wide research prospect in the fields of environmental governance and the like, and is suitable for large-area production and application.

Owner:SHAANXI SCI TECH UNIV

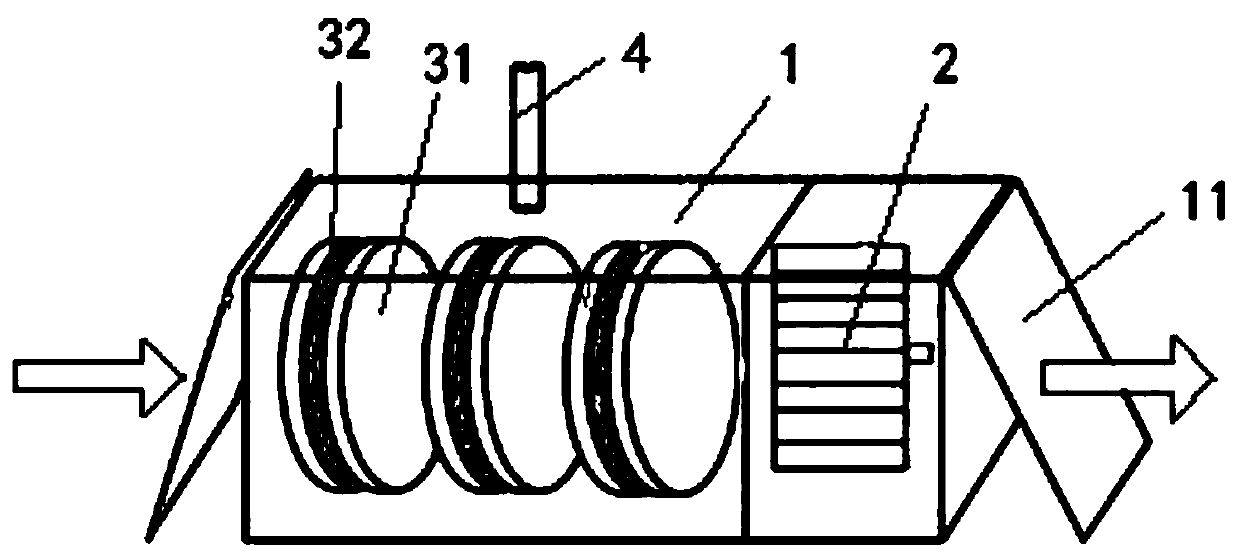

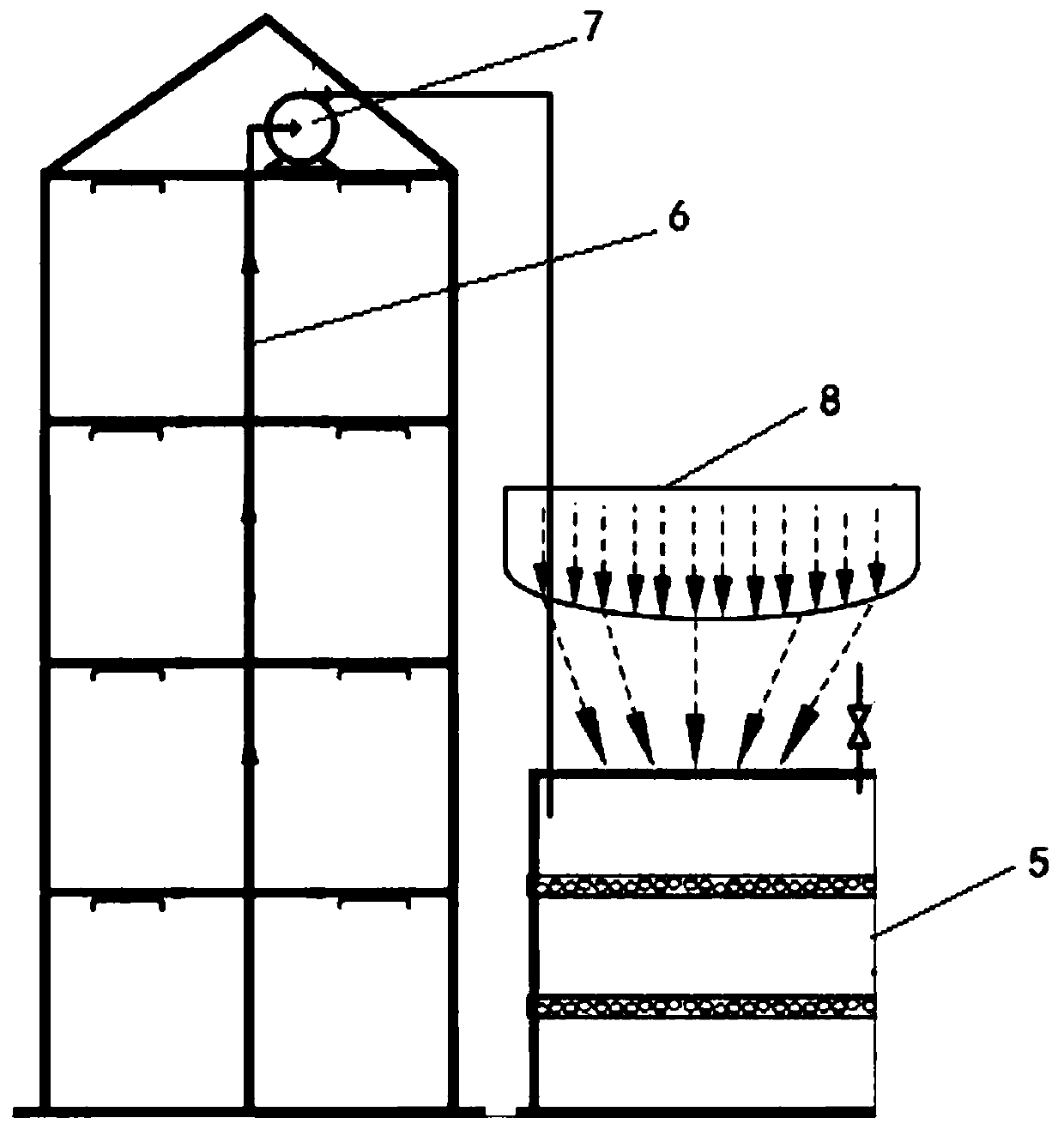

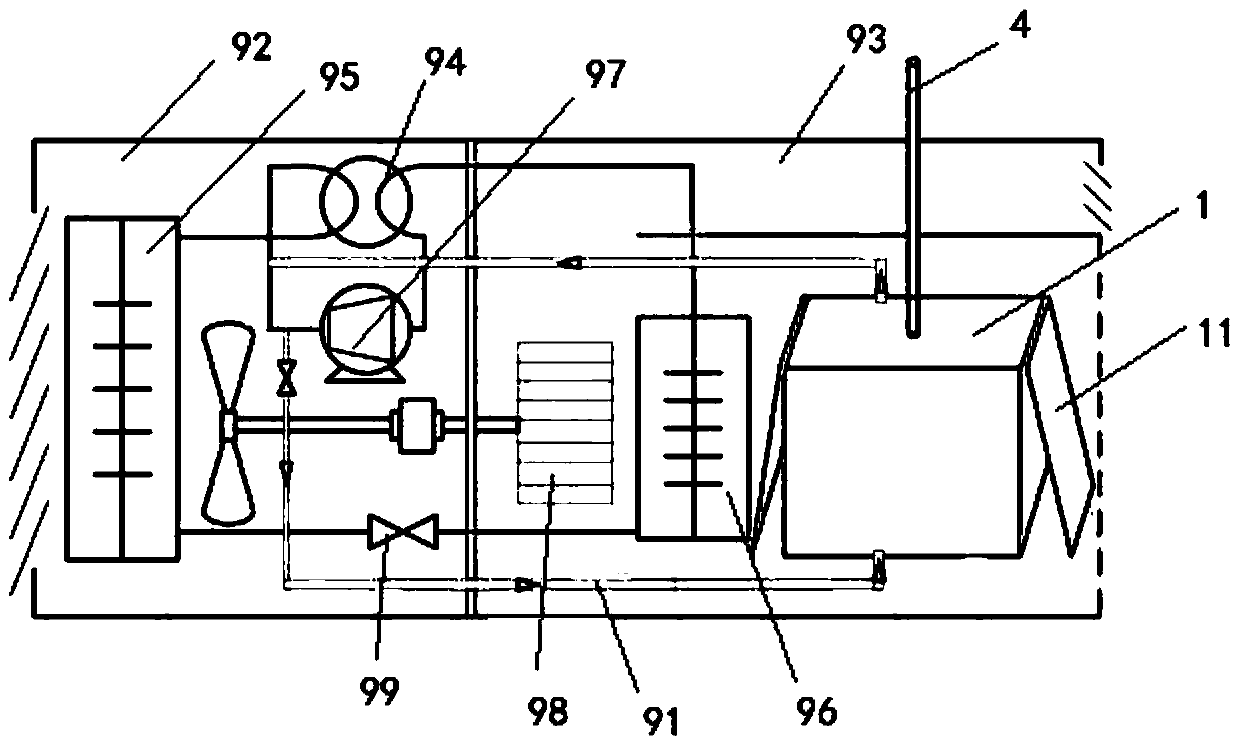

CO2 trapping device, CO2 conversion device and carbon trapping split type air conditioning system

PendingCN111375286AGood for healthQuality improvementGas treatmentLighting and heating apparatusIndoor air qualityAir conditioning

The invention discloses a CO2 trapping device, a CO2 conversion device and a carbon trapping split type air conditioning system. The CO2 trapping device comprises a box body, a fan and at least one CO2 catcher, wherein the fan and the at least one CO2 catcher are respectively arranged in the box body; the fan is used for sucking indoor air into the box body, so that the indoor air flows through the CO2 catcher; the CO2 catcher comprises at least one CO2 adsorption plate used for adsorbing CO2 in air flowing through the CO2 catcher and a heating piece used for heating the CO2 adsorption plate so that the CO2 adsorption plate can release the adsorbed CO2. According to the CO2 trapping device, passive control over CO2 in indoor air can be achieved, the indoor air quality is improved, meanwhile, the ventilation rate is reduced, and human health is facilitated.

Owner:江苏中关村科技产业园节能环保研究有限公司

Aquatic animal breeding method with performance testing and seed reserving separated

ActiveCN103749354AReduced seed retention rateChoice response boostClimate change adaptationPisciculture and aquariaAquatic animalZoology

The invention discloses an aquatic animal breeding method aiming to solve the problem that seed reserving rate is low in conventional breeding methods. Families for seed reserving and performance testing are separated, related heritability coefficients rA are calculated according to results of performance testing, and selection of different seed selection methods is performed according to calculation results. By the method, seed reserving rate is lowered on the premise of not increasing cost, and selection response is improved greatly, so that the purpose of accelerating breeding progress is achieved. Therefore, the method has broad market and scientific research prospects.

Owner:DALIAN HAIBAO FISHERY

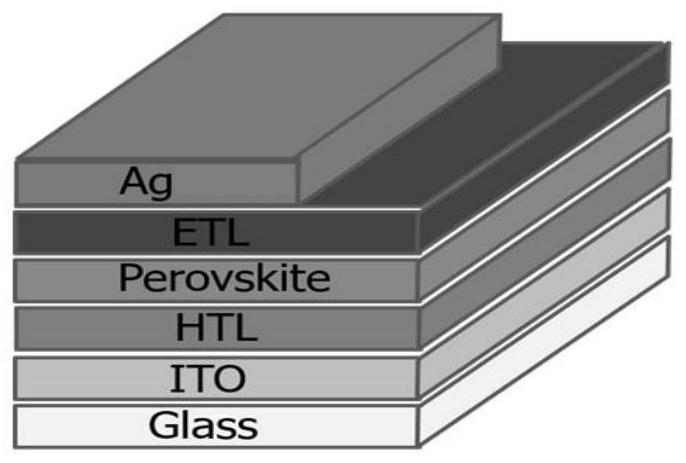

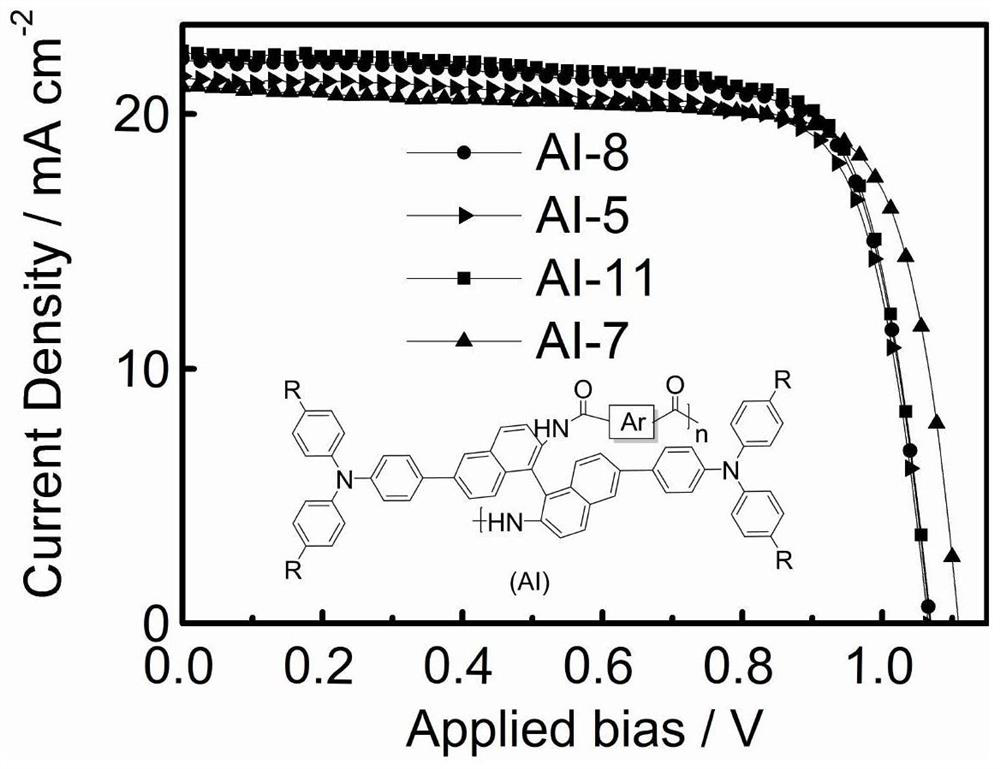

Amide bridged organic polymer hole transport material and synthesis method and application thereof

ActiveCN112778518AImprove solubilityImprove film formationSolid-state devicesSemiconductor/solid-state device manufacturingPolymer sciencePtru catalyst

The invention relates to an amide bridged organic polymer hole transport material and a synthesis method and application thereof. According to the design concept, a triarylamine group rich in electrons is used as an electron donating group, so that the conductivity is improved; and the binaphthalene ring structure is favorable for improving pi-pi accumulation among molecules, and meanwhile, the C2 symmetry axis of the binaphthalene ring enables the molecules to have a certain rotation angle, so that molecular aggregation is favorably inhibited. Experimental results prove that the amide bridged organic polymer hole transport material has very high hole mobility and thermal stability. In addition, the dissolvability of the molecule is improved by the non-conjugated structure of the amide group of the molecular skeleton. The designed amide bridged organic polymer molecule has a structure as shown in a formula (AI) defined in the description. The polymer has simple synthesis steps, no catalyst is added in the polymerization process, and the yield is high. The material has relatively high hydrophobicity, thermal stability, film-forming property and ductility, shows good photoelectric property and device stability when being applied to a perovskite solar cell as a hole transport material, and has a wide research prospect.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

A kind of preparation method of multistage sustained-release drug-loaded nano-short fibers

ActiveCN110201176BGrowth inhibitionOvercoming the problem of multidrug resistanceOrganic active ingredientsInorganic non-active ingredientsFiberSpinning

The present invention relates to a preparation method of multi-level sustained-release drug-loaded nano-short fibers, comprising layered double hydroxide (LDH) loaded with anticancer drug doxorubicin (DOX) and P-gp inhibitor α-growth Phenolsuccinate (α-TOS) was mixed together in poly(lactic-co-glycolic acid) (PLGA) spinning solution for electrospinning and homogenized. The present invention constructs double-loaded multi-level slow-release drug-loaded nano-short fibers with organic and inorganic dual carriers. The anticancer drugs and P-gp inhibitors in the material can be released in multiple levels in the slightly acidic environment of the tumor, and are used to overcome cancer. The multi-drug resistance of cells, the double-carrier nanofiber prolongs the drug release path, realizes the long-term sustained release of anticancer drugs, and provides a new method for the long-term effective treatment of drug-resistant tumors.

Owner:DONGHUA UNIV

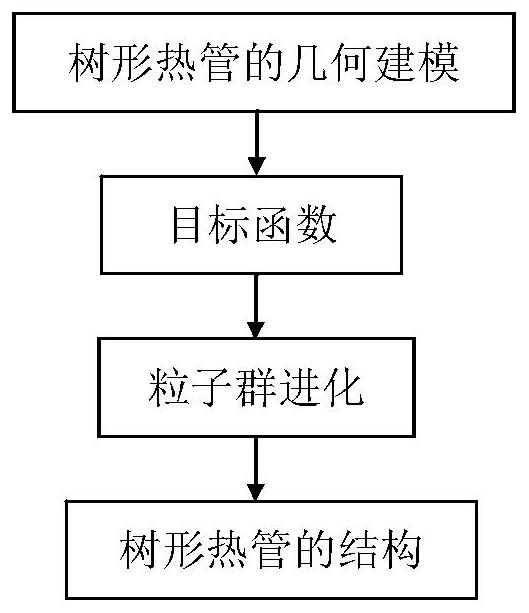

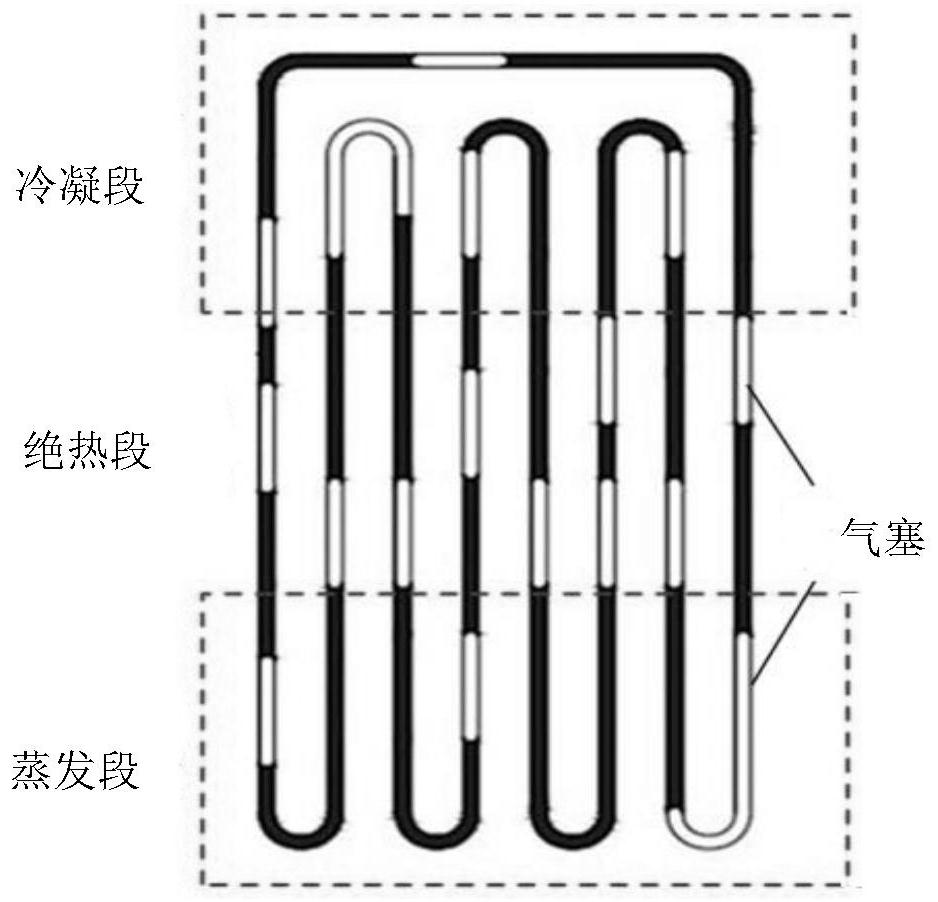

Method for designing structure of tree-shaped heat pipe by using particle swarm evolution and application

PendingCN114510844AImprove heat transfer performanceImprove cooling effectArtificial lifeIndirect heat exchangersHeat flowGeometric modeling

The invention discloses a method for designing the structure of a tree-shaped heat pipe through particle swarm evolution and application. According to the method, the evaporation section of the tree-shaped heat pipe is designed through the steps of geometric modeling of the tree-shaped heat pipe, establishment of the target function for designing the tree-shaped heat pipe according to the requirements of thermal design, calculation of the target function through the particle swarm evolutionary algorithm and the like, and the tree-shaped heat pipe structure with the good heat transfer characteristic can be obtained. According to the structure, the heat dissipation capacity of the whole heat pipe in some areas with large heat flow density can be improved by increasing the distribution density of the micro-channels in the areas, and wide research prospects are achieved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

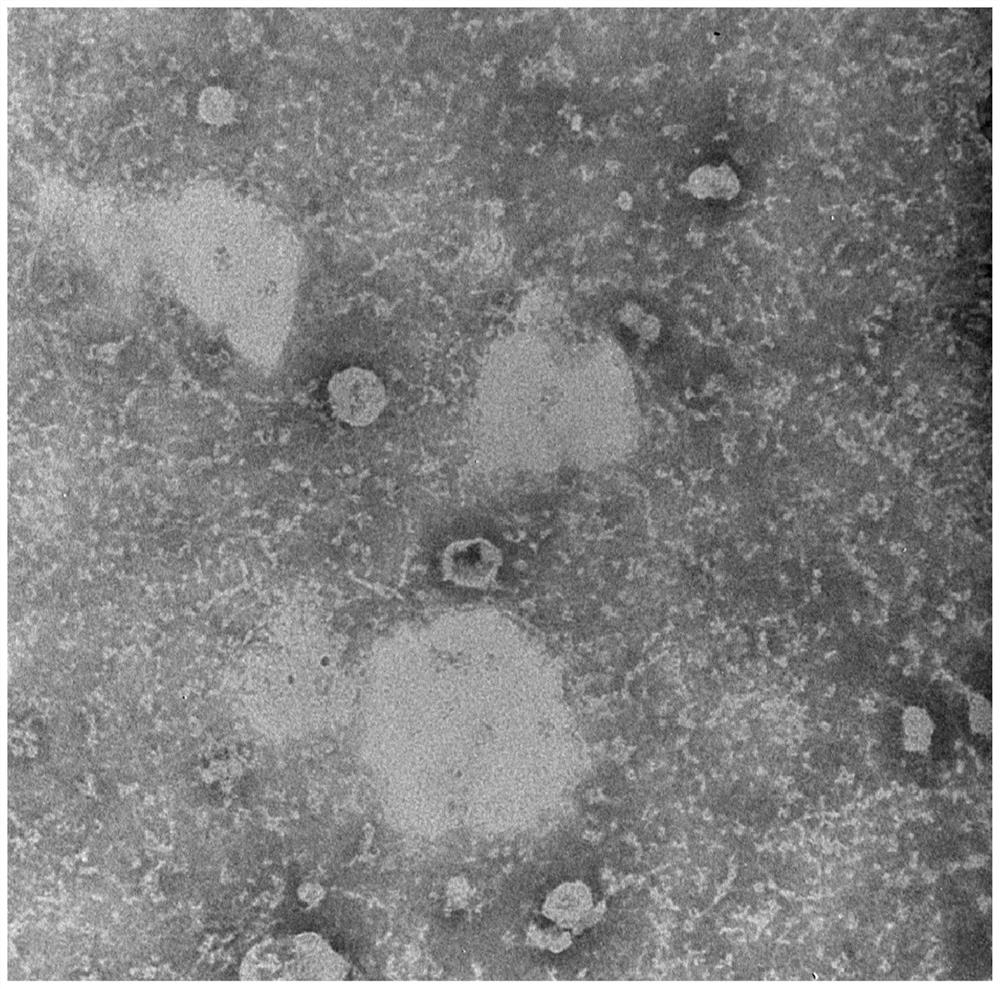

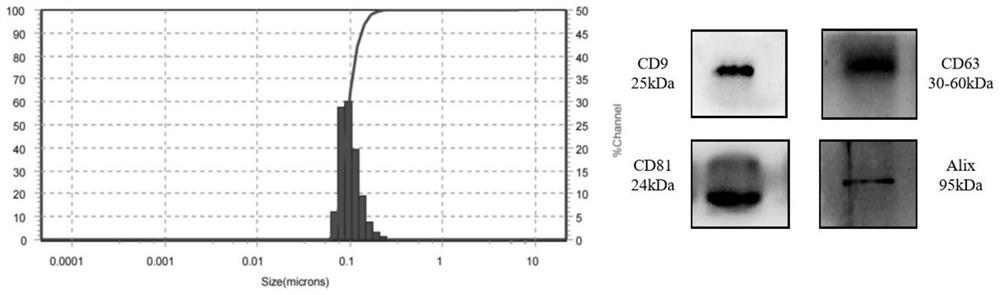

Mineralized collagen gel loaded with gingival mesenchymal stem cell exosome and preparation method thereof

PendingCN114642630APrevent regenerationInhibition of secretionAntipyreticAerosol deliverySodium phosphatesTherapeutic effect

The invention discloses mineralized collagen gel loaded with gingival mesenchymal stem cell exosomes and a preparation method of the mineralized collagen gel. The gel is prepared from the gingival mesenchymal stem cell exosome, mineralized collagen and chitosan / beta-sodium glycerophosphate. According to the invention, the exosome has anti-inflammatory and osteogenesis promoting effects, the mineralized collagen has osteoinductivity, the chitosan is antibacterial and has temperature-sensitive characteristic after the beta-sodium glycerophosphate is introduced, and the gel synthesized from the components can be injected into a bone defect area in a periodontitis state so as to promote local bone repair or bone amplification. The gel can improve the treatment effect of the exosome, significantly improve the drug absorption rate of the body and the local residence rate of the drug, has good biocompatibility and biological activity, provides a novel administration approach for macromolecular drugs, is an injectable use mode, and has good application prospects.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

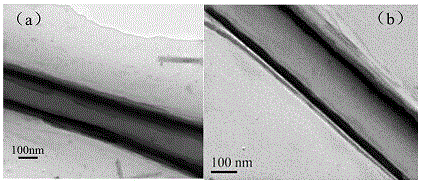

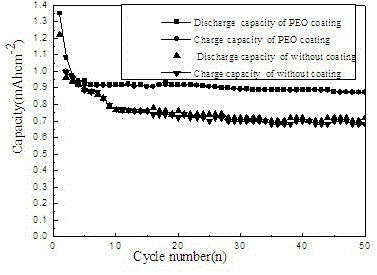

peo-coated hollow sn-ni alloy nanowire array, its preparation method and its application

ActiveCN104466103BEasy to prepareModerate and controllable conditionsMaterial nanotechnologyCell electrodesWettingVolume expansion

The invention discloses a PEO-coated hollow Sn-Ni alloy nanowire array, its preparation method and its application in lithium battery negative electrode materials, which solves the problem of poor stability of existing existing three-dimensional structure nanowires as lithium battery negative electrode materials The present invention includes steps: 1) preparing Ni nanowires by constant current electrodeposition; 2) using Ni nanowires as a template to prepare hollow Sn-Ni alloy nanowire arrays through current displacement reaction; 3) preparing by PEO solution infiltration method PEO-coated hollow Sn‑Ni alloy nanowire arrays. The prepared PEO-coated hollow Sn‑Ni alloy nanowire array was used as the negative electrode, and the lithium-ion battery was assembled and tested for performance. The reversible specific capacity of the PEO-coated hollow Sn‑Ni alloy nanowire array remained at 0.88 mAhcm‑after 200 cycles. 2. This is mainly due to the flexibility of the polymer and the buffering effect of its internal hollow structure on volume expansion.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

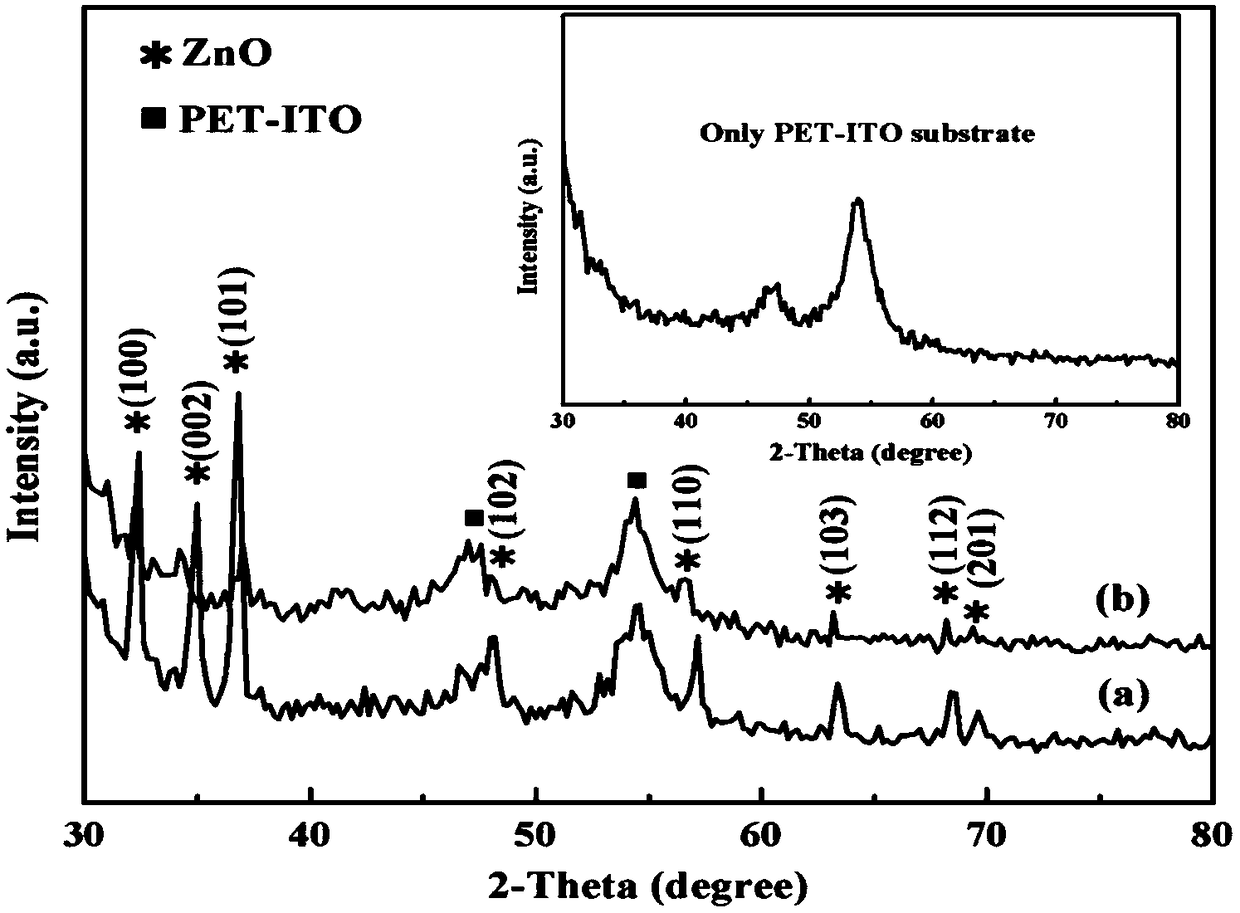

A boron-doped zinc oxide lamellar ball/p-type pet-ito heterojunction and its preparation method and application

InactiveCN106373992BImprove electrical performanceReduce compoundingMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsNano structuringPtru catalyst

The invention provides a boron-doped zinc oxide lamella sphere / p-type PET-ITO heterojunction and its preparation method and application. During preparation, zinc nitrate hexahydrate, methenamine and boric acid are used as main reactants. First, a very thin ZnO seed crystal layer is ion-sputtered on the surface of the flexible substrate PET-ITO; then boron-doped zinc oxide precursor solutions with different concentrations are prepared; then on the vertically placed flexible substrate, the hydrothermal method Grow B-doped ZnO nanostructures to obtain B‑ZnO / PET‑ITO heterojunctions that can be used as catalysts. The product obtained through the hydrothermal reaction of the present invention has a special lamellar spherical morphology, typical rectification characteristics, has a strong degradation effect on the colored azo dye Reactive Yellow 15, and has broad application in the fields of heterojunction diodes, environmental management and other fields. The research prospects are suitable for large-scale production and application.

Owner:SHAANXI UNIV OF TECH

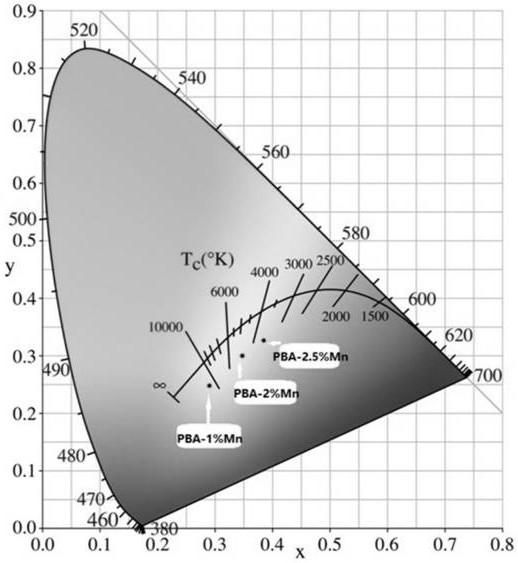

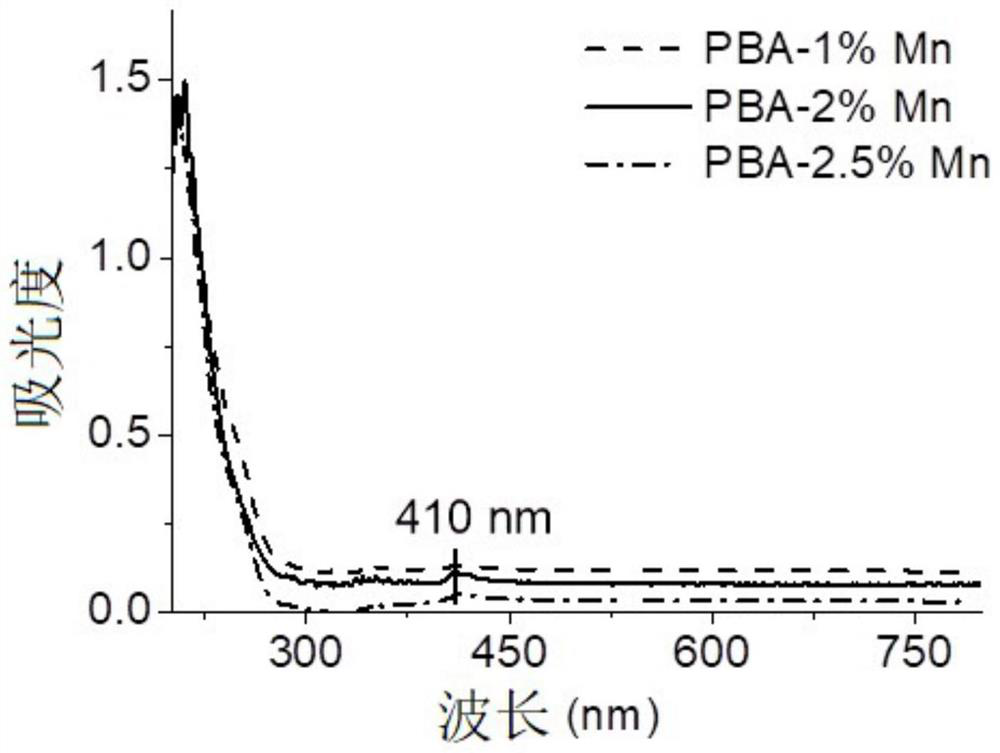

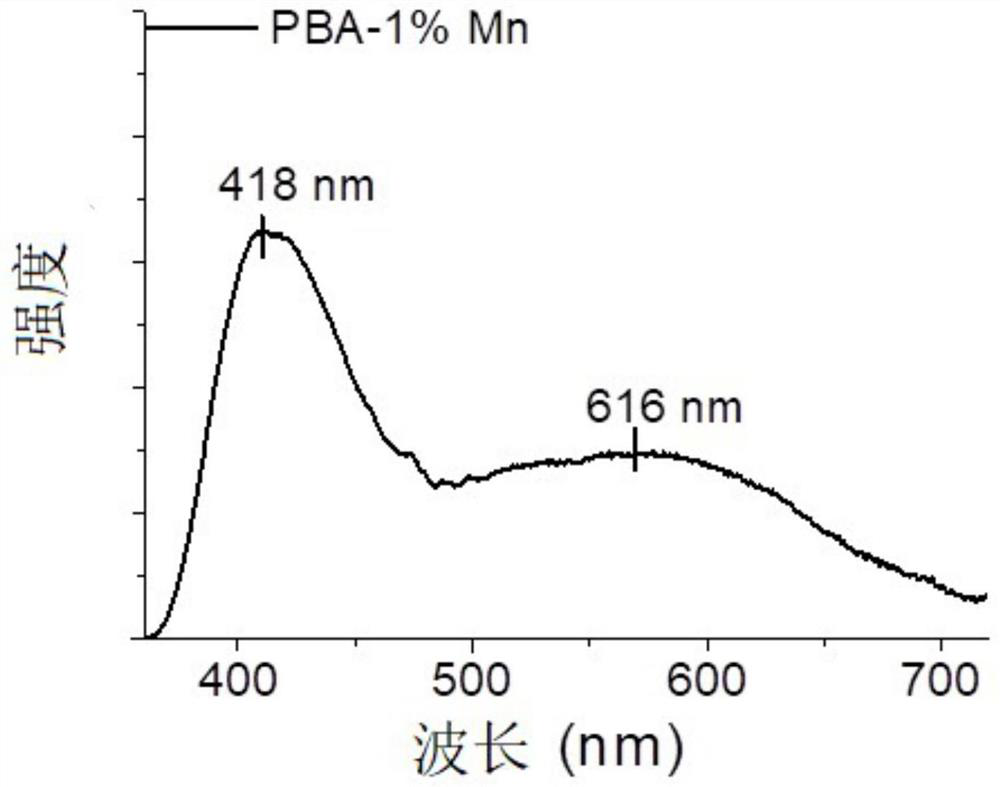

A kind of fluorescent glass material and preparation method thereof, lampshade and lamp

ActiveCN109437561BEasy to prepareReduce manufacturing costGlobesSemiconductor devices for light sourcesChemical compositionHigh volume manufacturing

The invention belongs to the field of optical technology, and in particular relates to a fluorescent glass material, a preparation method thereof, a lampshade and a lamp. The invention provides a kind of fluorescent glass material, the chemical composition of fluorescent glass material is (P 2 o 5 ) 0.56 (B 2 o 3 ) 0.15 (Al 2 o 3 ) 0.20 (ZnF 2 ) 0.10 (MnO) x ; where, 0.01≤x≤0.025. The fluorescent glass material of the present invention can emit white light under the excitation of the excitation light source, and the emitted white light is obtained by mixing blue-violet light with a peak value of about 410nm and yellow light with a peak value of 520nm and 580nm. Compared with traditional fluorescent powder, the fluorescent glass material of the present invention , has better thermal stability, avoids the problem of uneven dispersion of phosphor powder in organic resin, reduces the loss caused by light scattering, and the production cost of the fluorescent glass material of the present invention is low, simple to prepare, and convenient Processed into various shapes, suitable for mass production.

Owner:GUANGDONG UNIV OF TECH

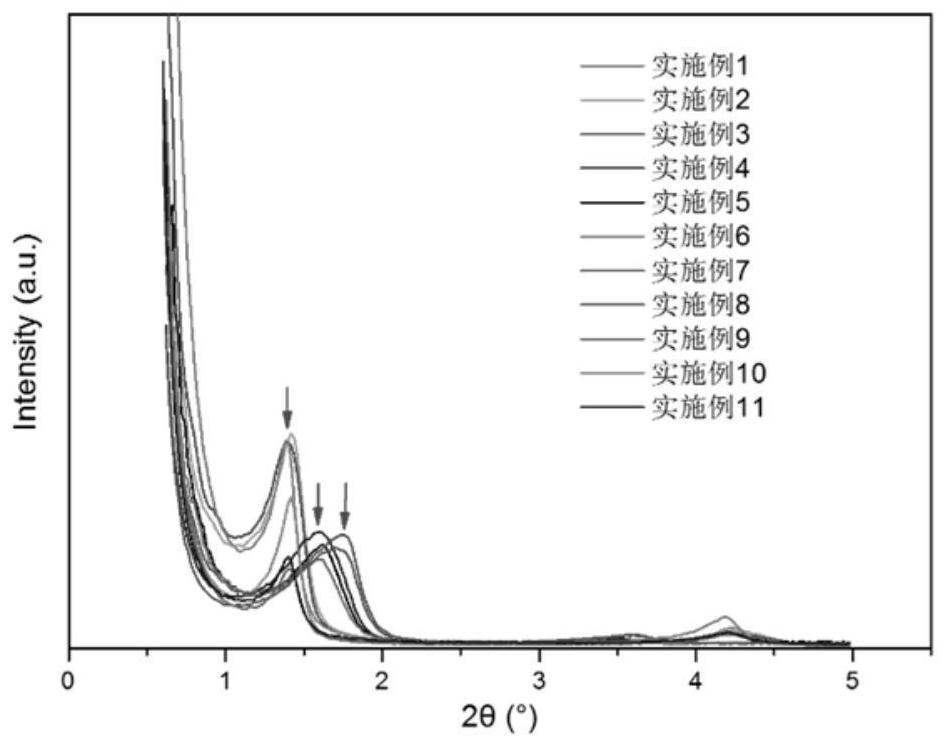

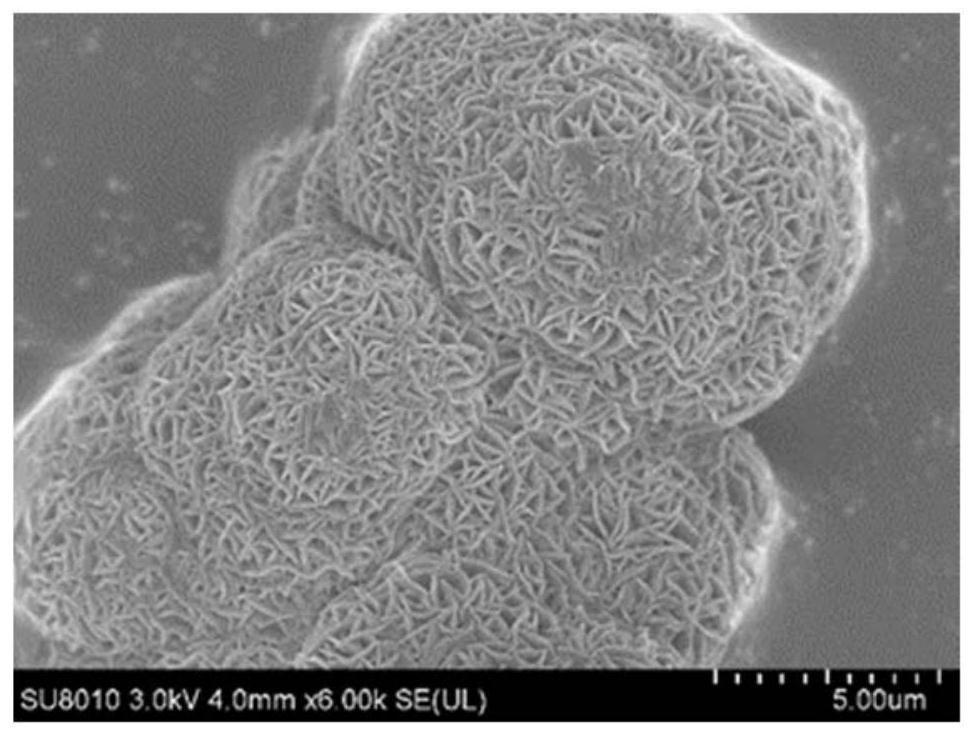

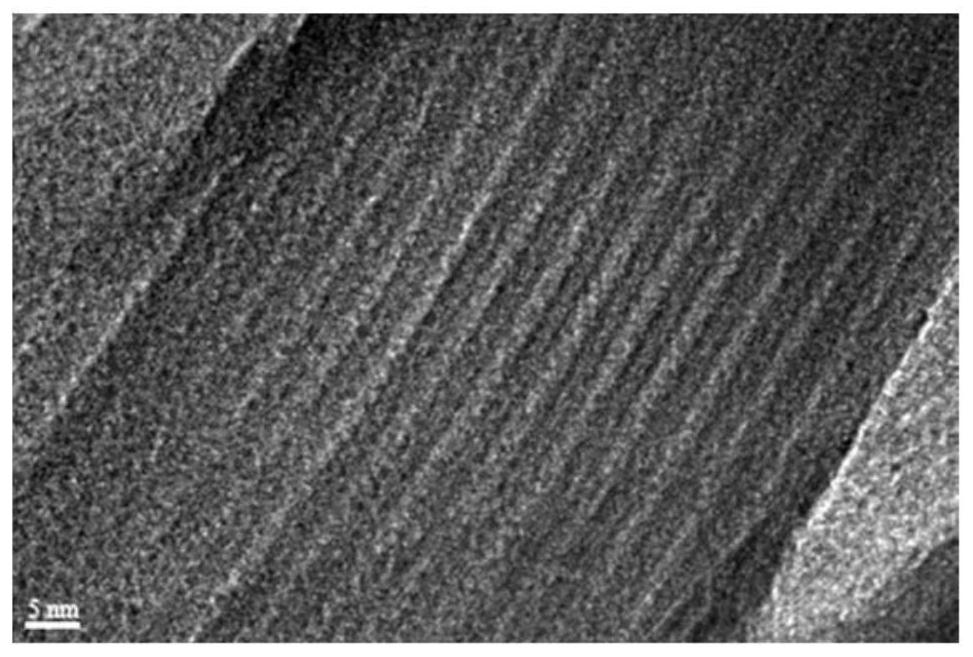

Variable pillared ZSM-5 nanosheet molecular sieve and preparation method thereof

ActiveCN113929110APlay a role of support and protectionFor precise controlMolecular sieve catalystsBulk chemical productionMolecular sievePtru catalyst

The invention discloses a variable pillared ZSM-5 nanosheet molecular sieve and a preparation method thereof, and belongs to the technical field of catalysts. The pillared molecular sieve is composed of orderly arranged nanosheet layers and interlayer MFI structure columns, the pillared height is adjustable in the range of 4-7nm, and the method specifically comprises the following steps: 1) dissolving an inorganic base, an inorganic acid, a small molecule template agent, a silicon source and an aluminum source in water, and uniformly stirring to form gel; 2) aging under a stirring condition; (3) continuously adding a long-carbon-chain amphiphilic surfactant solution and uniformly stirring; 4) aging under a stirring condition; and (5) crystallizing to obtain the pillared ZSM-5 nanosheet molecular sieve. According to the preparation method disclosed by the invention, the limitation of single pillared interlayer spacing in pillared preparation of the nanosheet molecular sieve at the present stage is solved, the nanosheet molecular sieve with the variable pillared interlayer spacing is prepared by a double-template method, and the prepared variable pillared ZSM-5 nanosheet molecular sieve can be used as a catalyst in the catalytic fields of preparation of low-carbon olefins and the like, and has high catalytic activity.

Owner:ZHEJIANG UNIV

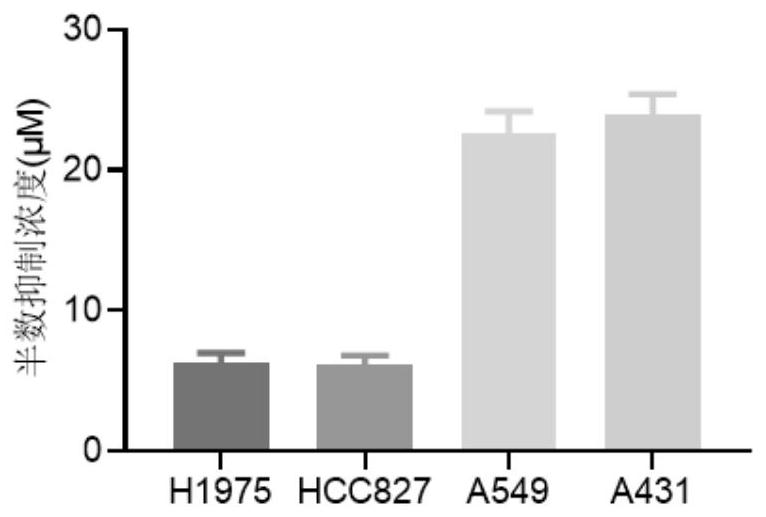

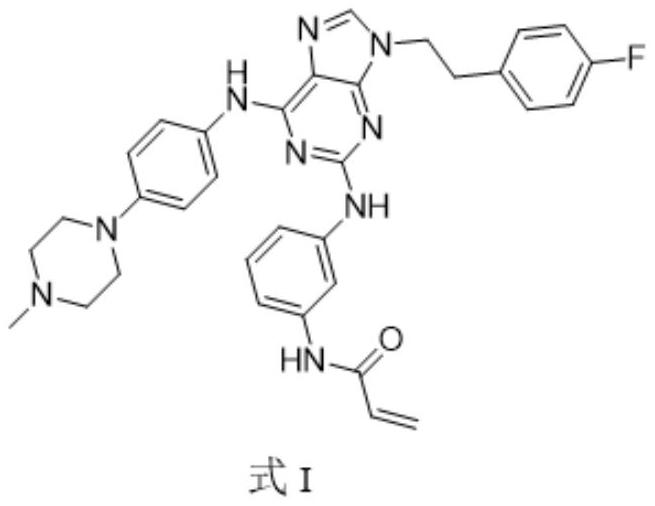

2, 6-disubstituted purine compound as well as preparation method and application thereof

ActiveCN114805369AStrong antiproliferative activityGood antiproliferative activityOrganic chemistryAntineoplastic agentsCancer cellPurine

The invention belongs to the technical field of anti-tumor pharmacy, and particularly relates to a 2, 6-disubstituted purine compound and application thereof, and the compound or pharmaceutically acceptable salt thereof, which can be used as an inhibitor of targeted EGFR L858R / T790M, has anti-tumor activity, can effectively inhibit the growth of cancer cells, and is simple in production method and low in cost.

Owner:ZIGONG NO 4 PEOPLES HOSPITAL

D-type graphite cast iron containing lead, arsenic and tin

Owner:FUZHOU UNIV

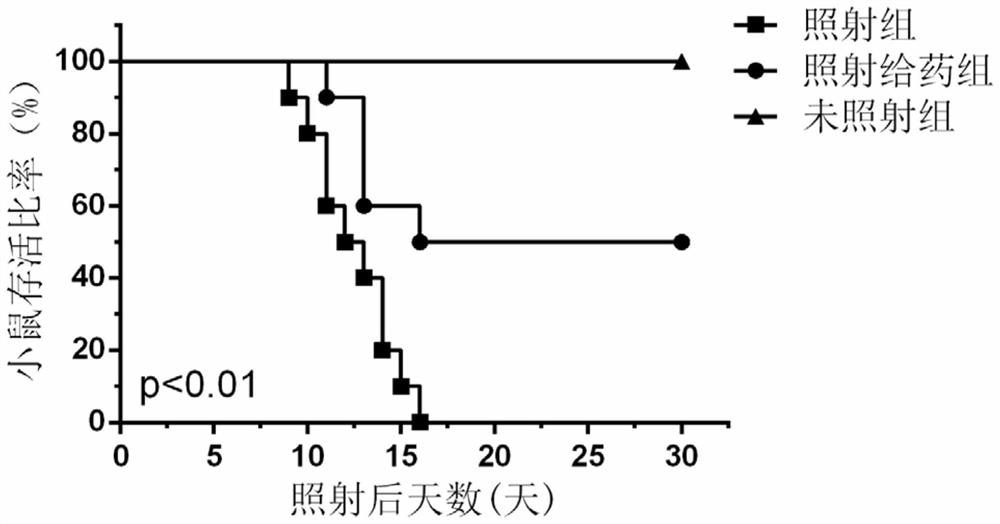

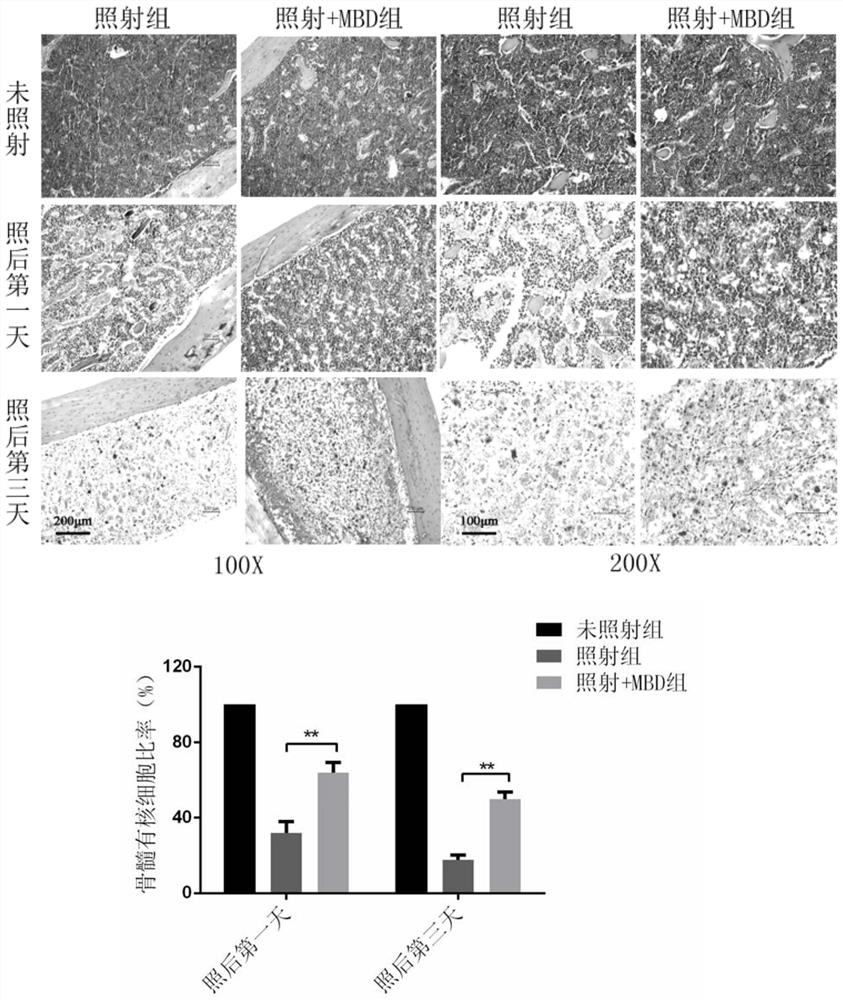

Application of murabutide in the preparation of drugs for the prevention and treatment of bone marrow, small intestine and spleen damage caused by ionizing radiation

ActiveCN110075269BEffective damage preventionSmall toxicityDipeptide ingredientsAntinoxious agentsSide effectOrgan damage

The invention relates to the field of new applications of medicines, in particular to the application of murabutide in the preparation of medicines for the prevention and treatment of bone marrow, small intestine and spleen damage caused by ionizing radiation. The murabutide provided by the invention has the advantages of low toxic and side effects, obvious prevention and treatment effect on radiation-sensitive organ damage, and the like as a medicine for preventing and treating bone marrow, small intestine, and spleen damage caused by ionizing radiation. It shows the unique advantages of murabutide in the prevention and treatment of multiple radiation-sensitive organ damage caused by ionizing radiation, and the purpose is to explore more efficient and low-toxicity treatment methods for the prevention and treatment of ionizing radiation damage; at present, there is still a lack of effective prevention and treatment of multiple organ damage caused by ionizing radiation at home and abroad Technical means are also one of the key problems that urgently need to be studied and solved in the field of radiology and clinical radiotherapy. Therefore, murabutide has broad development and application prospects in the field of medicine in my country as a drug for the prevention and treatment of multiple organ damage caused by ionizing radiation.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

A method for leaching lithium from fly ash

ActiveCN107130119BImprove refined utilization valueReflect the value of industrial applicationProcess efficiency improvementFiltrationMass ratio

Owner:HEBEI UNIV OF ENG

A kind of hard carbon negative electrode material for high-performance lithium-ion power battery, its preparation method and application

ActiveCN105355867BEasy to prepareModerate and controllable conditionsCell electrodesSecondary cellsPower batteryO-Phosphoric Acid

The invention discloses a hard carbon negative electrode material for a high-performance lithium-ion power battery, a preparation method and an application thereof, belonging to the field of electrochemistry. Phosphorus is doped in the hard carbon negative electrode material of the present invention, the mass ratio of phosphorus precursor and hard carbon precursor is 8-11:6, and described hard carbon precursor is phenolic resin, and described phosphorus precursor is phosphoric acid; The particle size range of the hard carbon negative electrode material is 10-50 microns. The rate performance of the hard carbon negative electrode material of the invention is obviously improved, and has broad research prospects in the field of practical application of power batteries.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

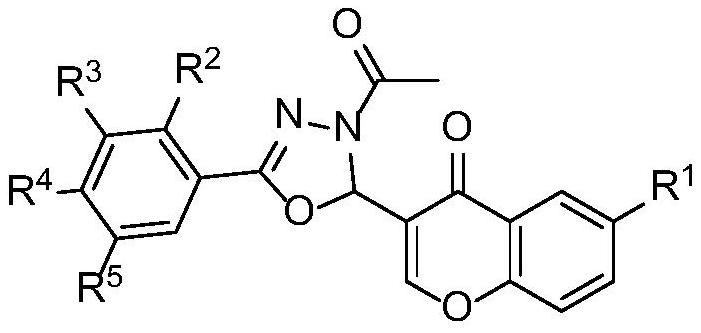

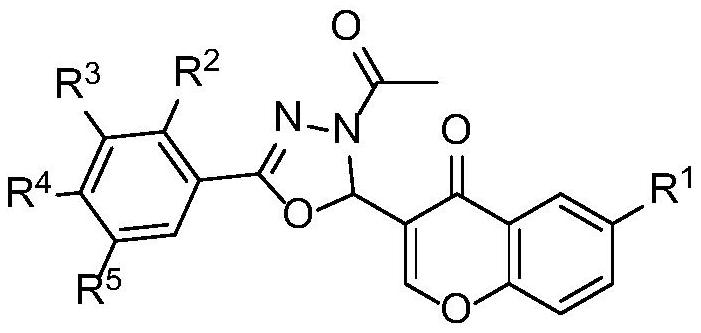

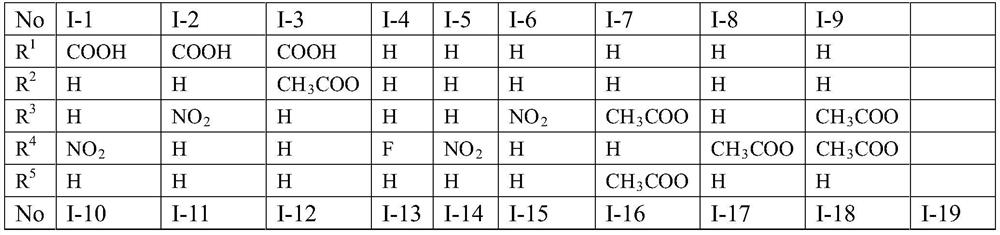

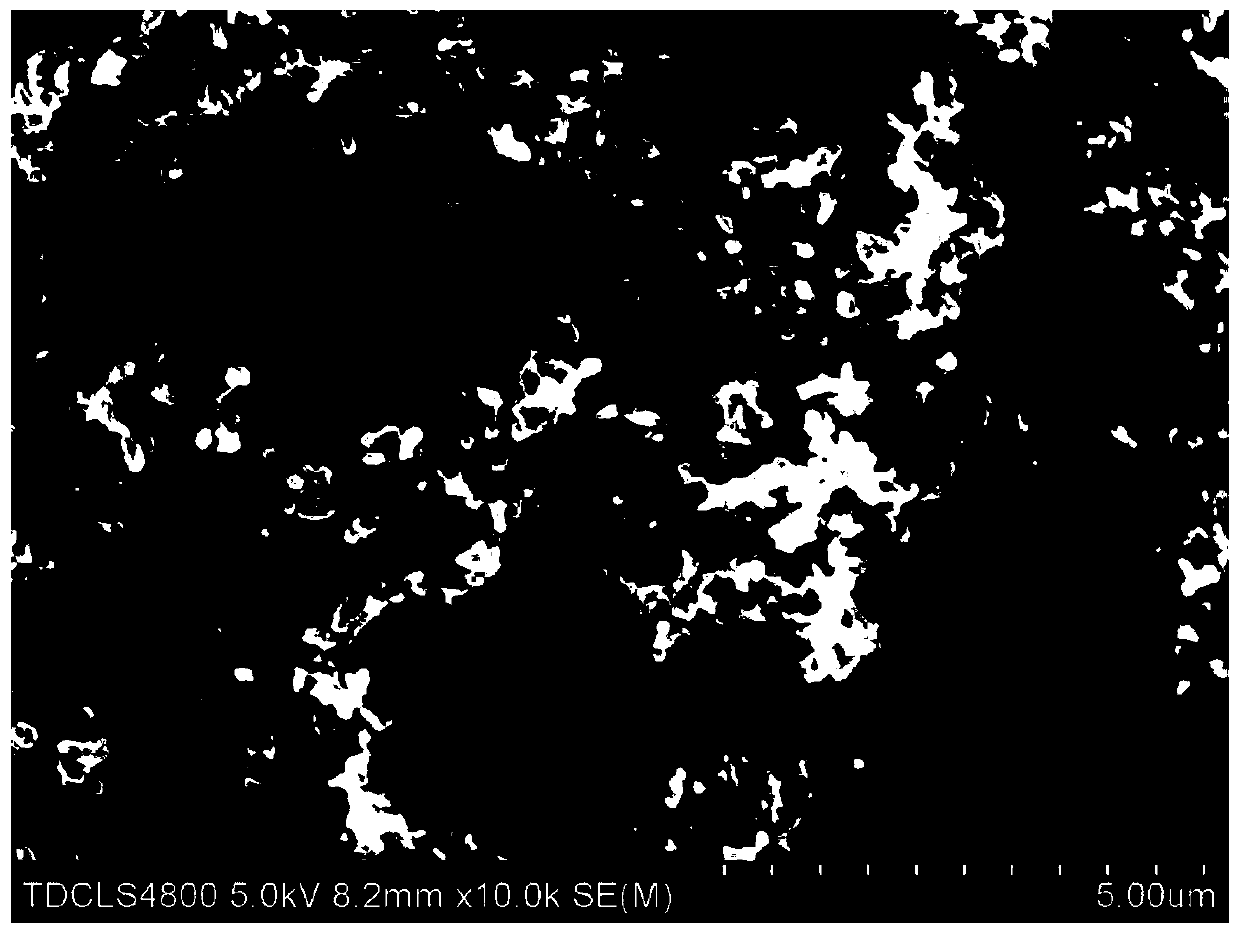

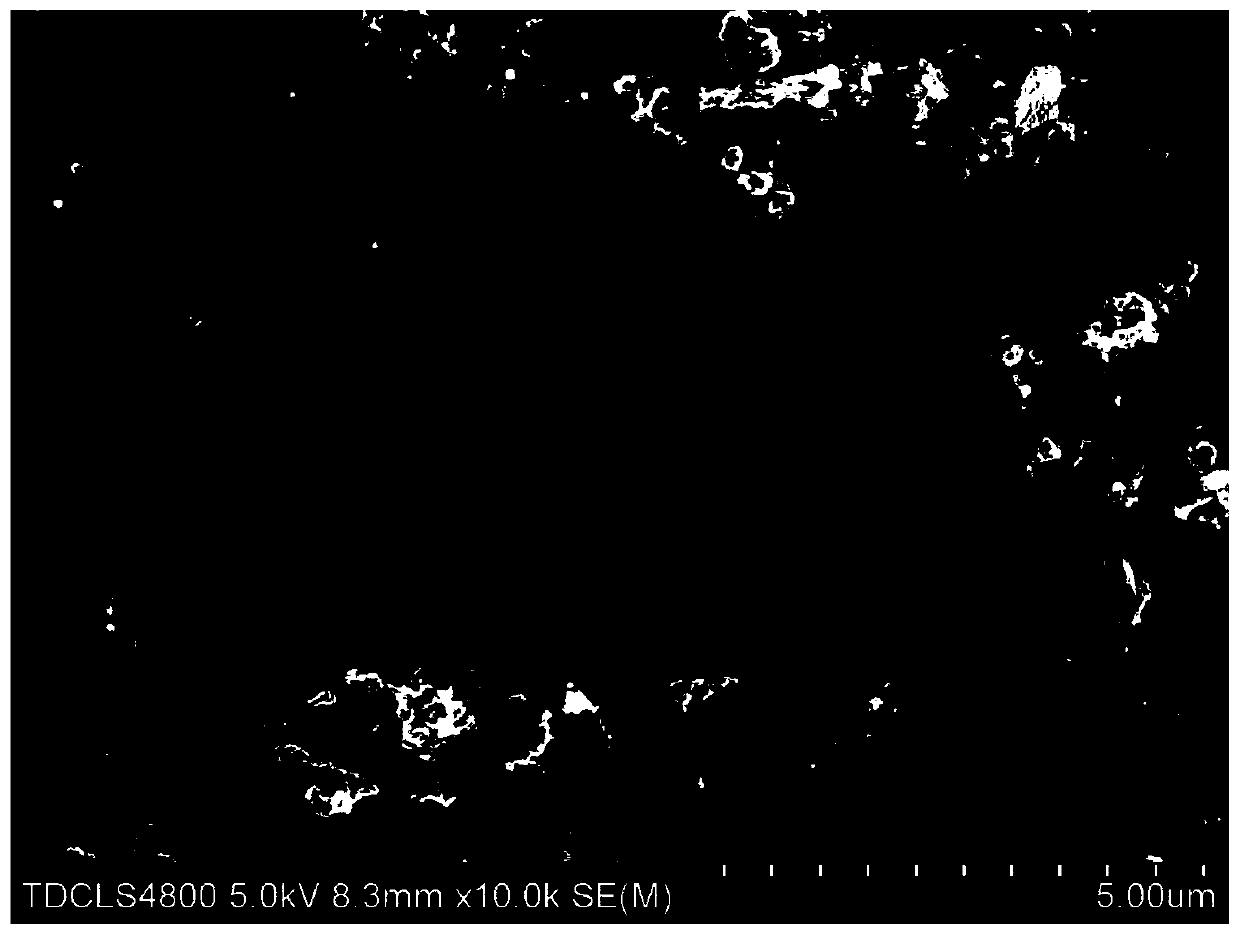

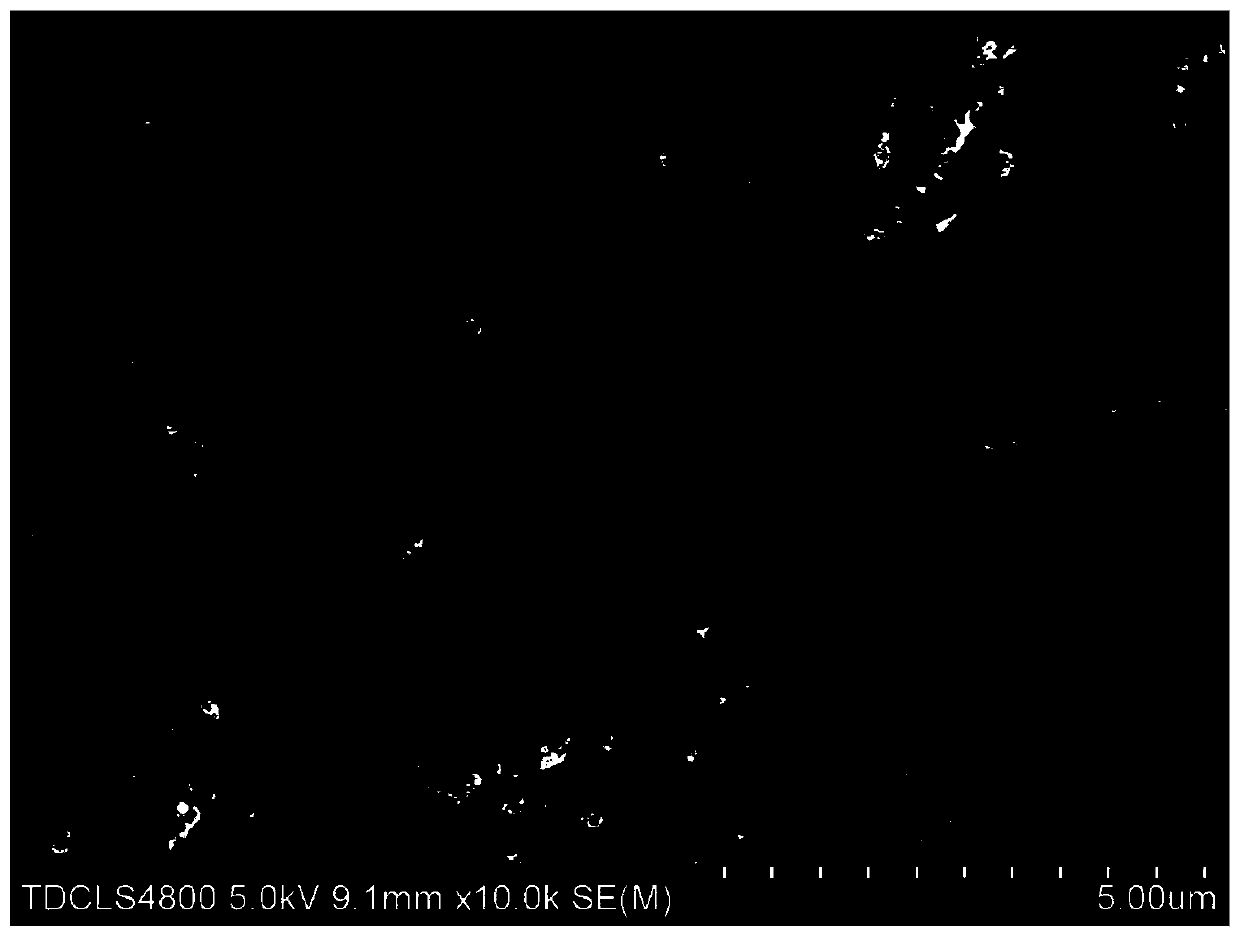

Chromone oxadiazoline compound as well as preparation method and application thereof

The invention discloses a chromone oxadiazoline compound and a preparation method and application thereof. The preparation method comprises the following steps: under the action of acetic anhydride, subjecting a compound shown in a formula II to shrinkage cyclization to obtain an oxadiazoline ring, and subjecting N on the oxadiazoline ring to acetylation reaction under the action of acetic anhydride to obtain a chromone oxadiazoline compound. The invention provides the novel preparation method of the chromone oxadiazoline compound, the defects of high toxicity and high preparation cost of traditional methods are overcome, and the obtained chromone oxadiazoline compound with a novel structure has a wide research prospect in new drug research.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Preparation method and application of graphene-modified conductive polymer gel-coated metal nanoparticles

ActiveCN106229514BImprove cycle stabilityGood electrochemical behaviorCell electrodesSecondary cellsPolypyrroleConductive polymer

The invention relates to a preparation method of metal nano-particles coated with graphene modified conductive polymer gel. The method comprises the steps of firstly mixing tin-nickel nano-particles with oxidized graphene solution uniformly, then adding pyrrole, oxidizing agents and dopants, and after full reaction, cooling and drying samples, thus acquiring the metal nano-particles coated with graphene modified conductive polymer gel. The metal nano-particles coated with graphene modified conductive polymer gel prepared by the invention are of three-dimensional porous structures, the particles are uniformly distributed in graphene sheets and gel, and polypyrrole gel is tightly connected with the graphene sheets. An electrode prepared by using tin-nickel nano-particles coated with graphene modified conductive polymer gel has high cycling stability and long service life. Cycle performance of a battery can be improved by taking the tin-nickel nano-particles coated with graphene modified conductive polymer gel prepared according to the method of the invention as the negative electrode material, and a new research method is provided for solving a volume expansion problem caused by taking the tin-base material as the negative electrode material of the lithium ion battery.

Owner:TIANJIN UNIV

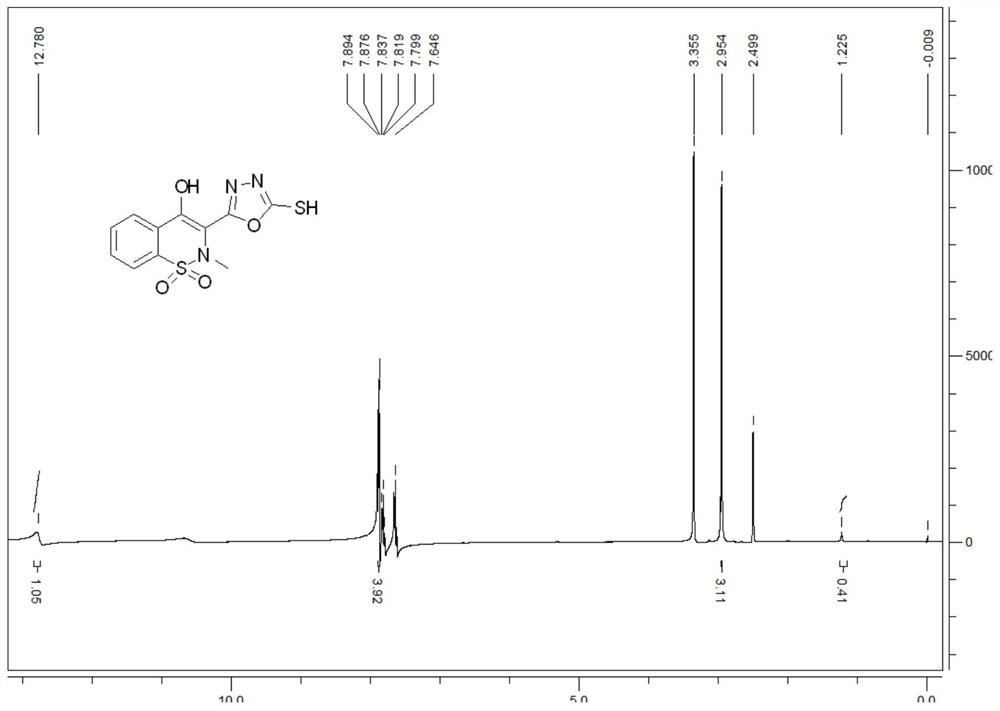

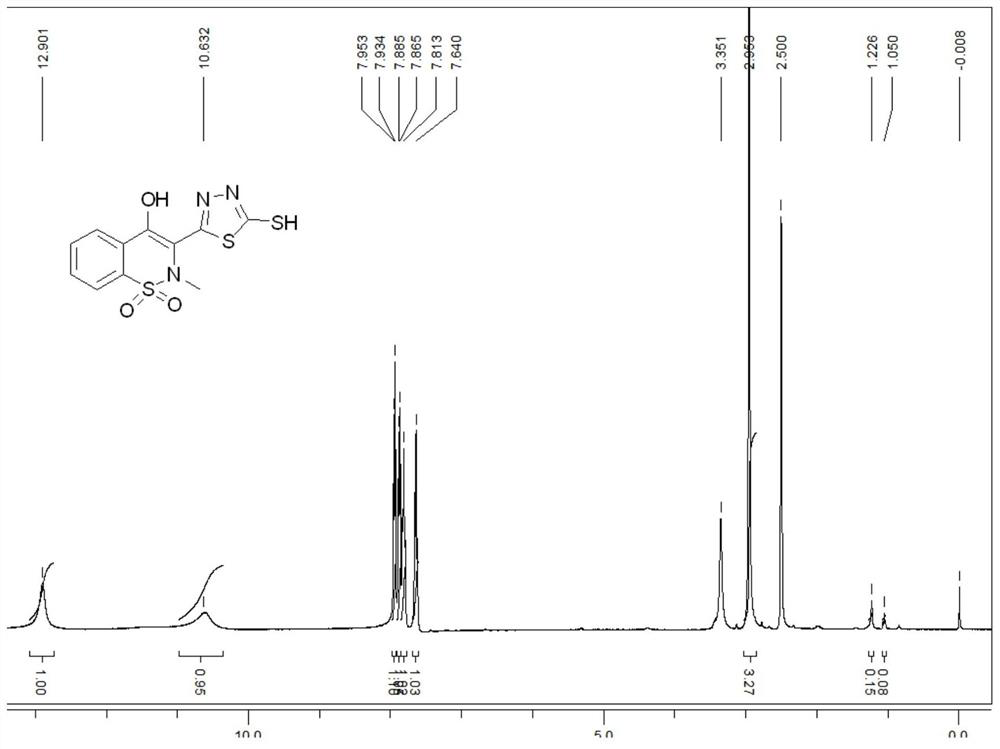

1, 2-benzothiazine heterocyclic derivative as well as preparation method and application thereof

ActiveCN113527282AReduce electron cloud densityGood dispersionOrganic chemistryAntineoplastic agentsPharmaceutical drugPerylene derivatives

The invention belongs to the technical field of medicinal chemistry, and particularly relates to a 1, 2-benzothiazine heterocyclic derivative, the structural formula of which is formula I or formula II: a thiadiazole (oxadiazole) ring is introduced to the C-3 site of a 1, 2-benzothiazine ring, so that the 1, 2-benzothiazine heterocyclic derivative has higher anti-tumor activity, and the occurrence of adverse reaction is reduced; and the invention also provides a preparation method and application of the 1, 2-benzothiazine heterocyclic derivative. A thiadiazole (oxadiazole) ring is introduced to the C-3 site of a 1, 2-benzothiazine ring, and the obtained 1, 2-benzothiazine heterocyclic ring derivative has high anti-tumor activity, can be used as an anti-tumor drug, and has a wider research prospect in the aspect of tumor treatment.

Owner:齐鲁医药学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com