Hard carbon negative electrode material for high-performance lithium ion power battery, and preparation method and application of hard carbon negative electrode material

A negative electrode material and power battery technology, applied in the field of electrochemistry, can solve problems such as unsatisfactory continuous high-current discharge capacity, and achieve the effects of good electrochemical performance, simple preparation method, and mild and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

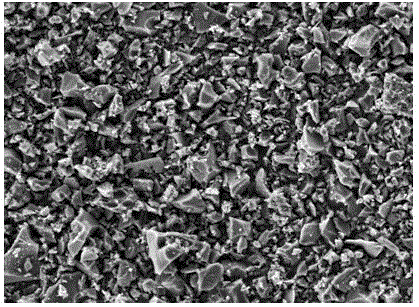

[0030] Weigh 30g of phenolic resin, stir and dissolve in 60mL of absolute ethanol, filter out impurities, add 40g of phosphoric acid to the filtrate while stirring; dry in a 50°C oven. The dried sample was put into a tube furnace, and carbonized at 800 °C for 8 h at a heating rate of 2 °C / min under an argon atmosphere. The carbonized sample was milled in a ball mill at 300 r / min for 8 h, and then passed 300 mesh sieve to obtain the hard carbon negative electrode material.

Embodiment 2

[0032] Weigh 30g of phenolic resin, stir and dissolve in 60mL of absolute ethanol, filter out impurities, add 55g of phosphoric acid to the filtrate while stirring; dry in an oven at 80°C. The dried sample was put into a tube furnace, and carbonized at 1000°C for 5h at a heating rate of 5°C / min under an argon atmosphere. The carbonized sample was milled in a ball mill at 400r / min for 6h, and then passed 400 mesh sieve to obtain the hard carbon negative electrode material.

Embodiment 3

[0034] Weigh 30g of phenolic resin, stir and dissolve in 60mL of absolute ethanol, filter out impurities, add 45g of phosphoric acid to the filtrate while stirring; dry in an oven at 80°C. The dried sample was put into a tube furnace, and carbonized at 1200 °C for 5 h at a heating rate of 8 °C / min under an argon atmosphere. The carbonized sample was ball milled in a ball mill at 800 r / min for 5 h, and then passed 600 mesh sieve to obtain the hard carbon negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com