Variable pillared ZSM-5 nanosheet molecular sieve and preparation method thereof

A technology of ZSM-5 and nanosheets, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, hydrocarbon cracking and hydrocarbon production, etc. It can solve the problems of limiting the diversity of pore structures and the inability to adjust the height of pillars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0029] [Example 1~8] 0.66g sodium hydroxide is dissolved in 3.12g deionized water, 0.49g H 2 SO 4 Dissolve in 4.2 g of deionized water, and add the acidic solution dropwise to the alkaline solution under vigorous stirring. After cooling to room temperature, 0.18 g of aluminum sulfate octadecahydrate was added to the mixture. Then, 0.89 g of tetrabutylammonium hydroxide and 5.73 g of tetraethylorthosilicate were added to the mixture in sequence, and the mixture was aged at 25° C. for 20 hours with vigorous stirring using a magnetic stirrer to form a gel. Finally, the above gel mixture was mixed with 1.99 g of C dissolved in 12.12 g of deionized water 22 h 45 -N + Br - (CH 3 ) 2 -C 6 h 12 -N + Br - (CH 3 ) 2 -C 6 h 13 (C 22-6-6 ) solution mixed. After stirring continuously at 25°C for 2 hours, the resulting gel was transferred to a 50ml reactor, and hydrothermally crystallized at 150°C for 5 days. During the crystallization process, the reactor was kept rotating...

Embodiment 1

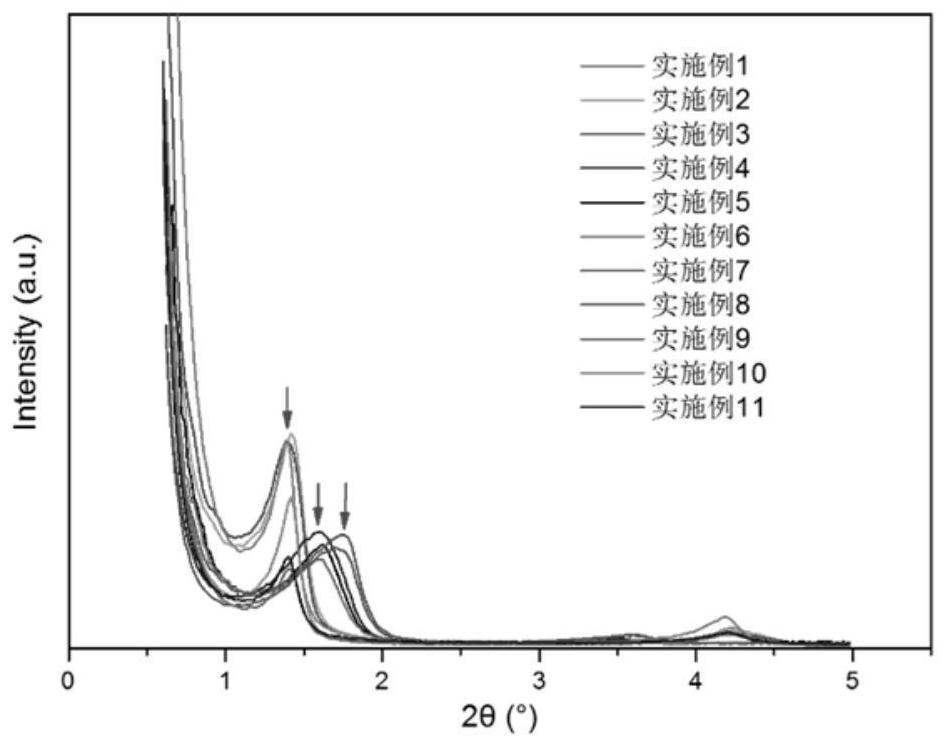

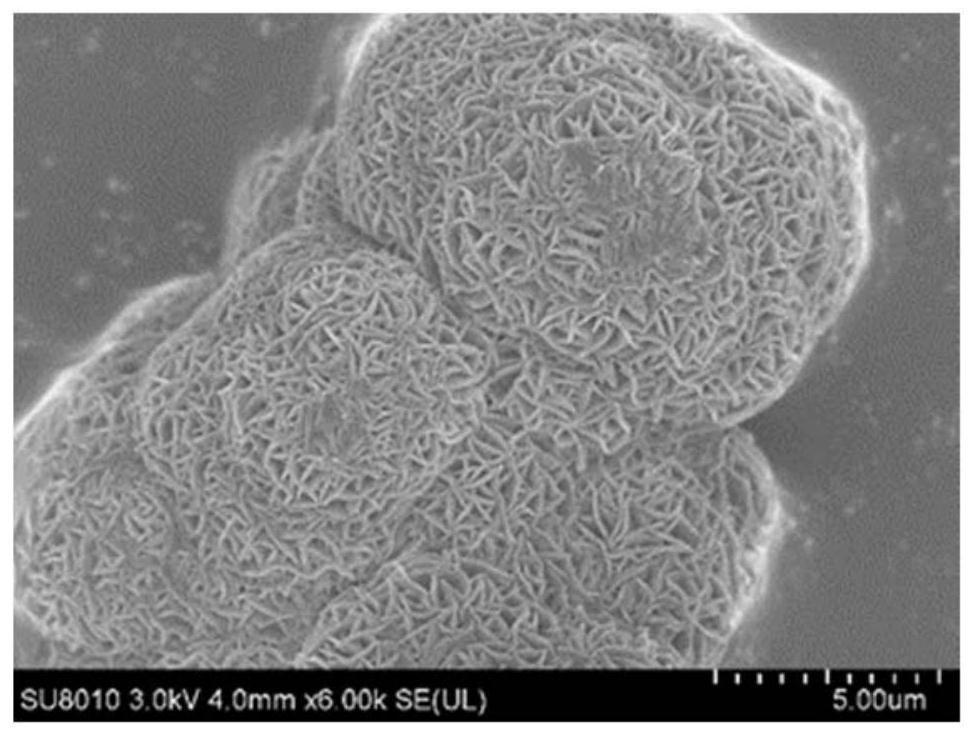

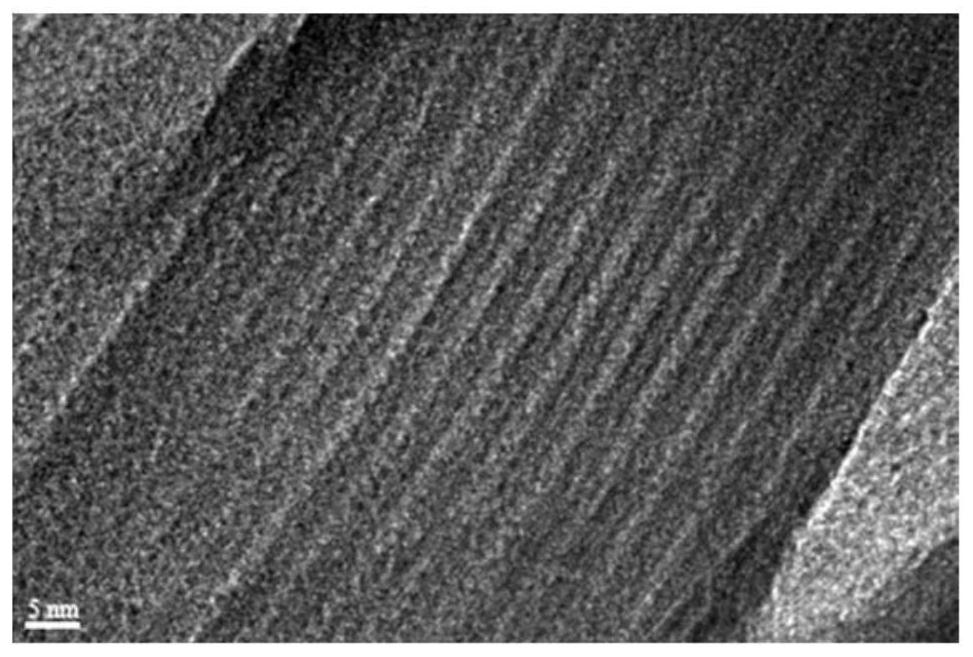

[0031] The small-angle X-ray diffraction figure of the prepared catalyst of embodiment 1-8 is as follows figure 1 shown. from figure 1 It can be seen from the figure that the double-template method realizes effective pillars between the nanosheets, making it form sharp characteristic peaks in small-angle X-ray diffraction. Adjustment effect, the prepared nanosheet molecular sieves have different interlayer thicknesses and pillar heights. The scanning electron microscope picture of embodiment 1 is as figure 2 As shown, the transmission electron microscope image is shown in image 3 shown. The pillared nanosheet molecular sieve exhibits the morphology of nanoflowers, and the nanosheets and mesoporous layers are arranged in an orderly manner in the microstructure.

Embodiment 9

[0032] [Example 9] Dissolving 0.66g sodium hydroxide in 3.12g deionized water, 0.49g H 2 SO 4 Dissolve in 4.2 g of deionized water, and add the acidic solution dropwise to the alkaline solution under vigorous stirring. After cooling to room temperature, 0.18 g of aluminum sulfate octadecahydrate was added to the mixture. Then, 0.89 g of tetrabutylammonium bromide and 5.73 g of tetraethylorthosilicate were added to the mixture in sequence, and the mixture was aged at 25° C. for 20 hours with vigorous stirring using a magnetic stirrer to form a gel. Finally, the above gel mixture was dissolved in 12.12 g deionized water with 1.99 g C 22-6-6 The solution is mixed. After stirring continuously at 25°C for 2 hours, the resulting gel was transferred to a 50ml reactor, and hydrothermally crystallized at 150°C for 5 days. During the crystallization process, the reactor was kept rotating at a constant speed of 40rmp, and a white mixture was obtained after crystallization. Solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com