Pre-sodium-modified sodium ion battery positive electrode, and pre-sodium-modified method and application thereof

A sodium-ion battery and positive electrode technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, positive electrodes, etc., can solve the problems of mismatching efficiency of positive and negative electrodes, low energy density of sodium-ion batteries, and great influence of electrode structure. Achieve the effect of improving energy density and cycle life, broad research prospects and application value, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for pre-sodiumization of positive electrode materials for sodium ion batteries is provided, comprising the following steps:

[0027] Under the protection of an inert atmosphere, biphenyl and sodium are mixed in an equimolar ratio, and are jointly dispersed in ethylene glycol dimethyl ether (DME) solvent, and the DME solution of the biphenyl sodium of 0.12mol / L is obtained after stirring, and then Na 0.44 MnO 2 Electrode (Na 0.44 MnO 2 : AB:PVDF=8:1:1) (active material loading is about 4mg) immersed in 1mL of DME solution of sodium biphenyl, reacted for 5min, washed with DME three times after the reaction, dried for later use, to obtain the pre- Sodiumized sodium ion battery cathode.

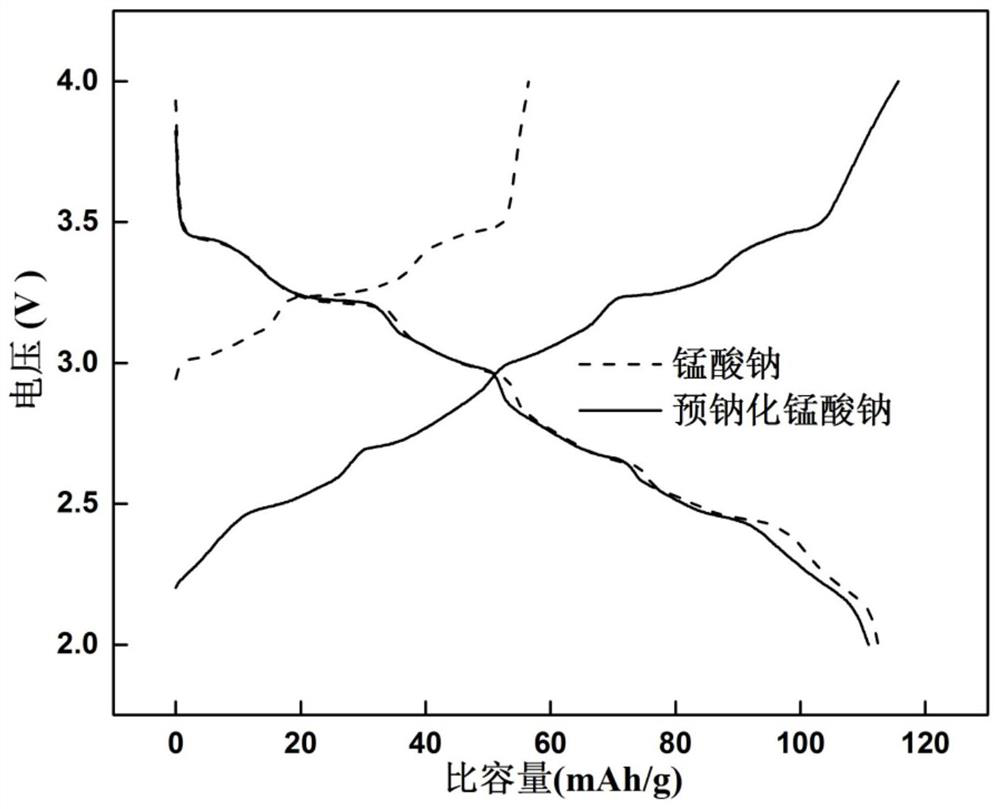

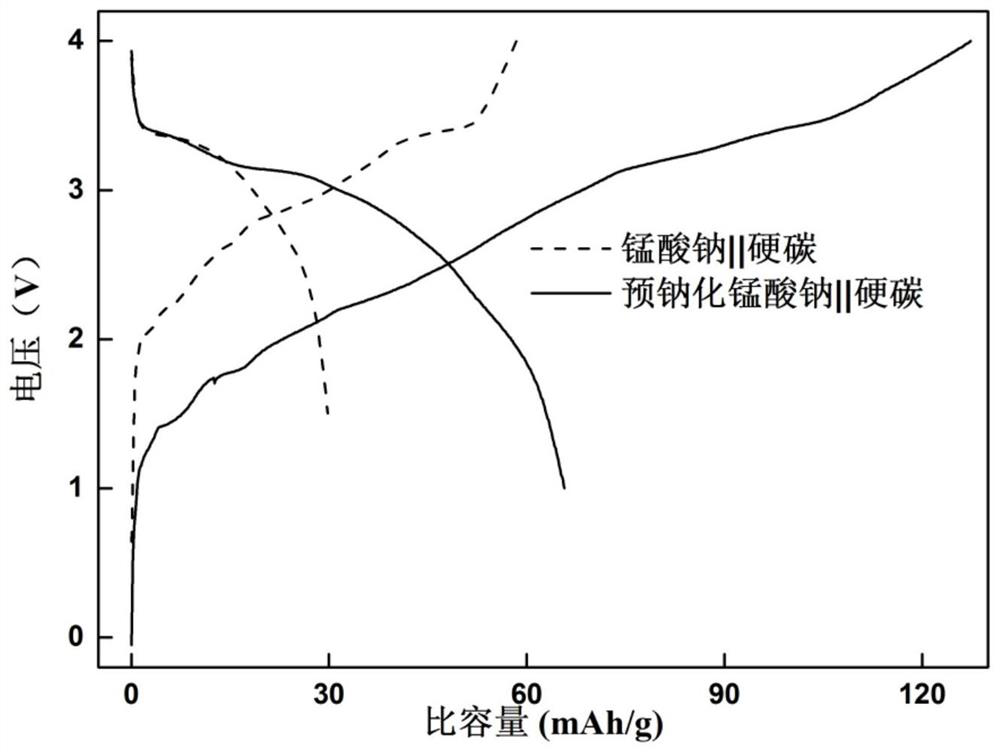

[0028] Na before and after presodiumization 0.44 MnO 2 The electrode is the positive pole, the sodium metal is the negative pole, use 1M NaClO 4 EC / DEC / FEC (v:v:v=10:10:1) electrolyte to assemble half-cells, and conduct charge and discharge tests. The charge-discharge curv...

Embodiment 2

[0031] A method for pre-sodiumization of positive electrode materials for sodium ion batteries is provided, comprising the following steps:

[0032] Under the protection of an inert atmosphere, mix naphthalene and sodium in an equimolar ratio, and disperse them in DME solvent together. After stirring, a DME solution of 0.1mol / L sodium naphthalene is obtained, and Na 3 V 2 (PO 4 ) 3 Electrode (Na 3 V 2 (PO 4 ) 3 : AB: PVDF = 8: 1: 1) (the active substance load is about 4 mg) immersed in 1 mL of DME solution of sodium naphthalene and reacted for 5 minutes. positive electrode of sodium-ion batteries.

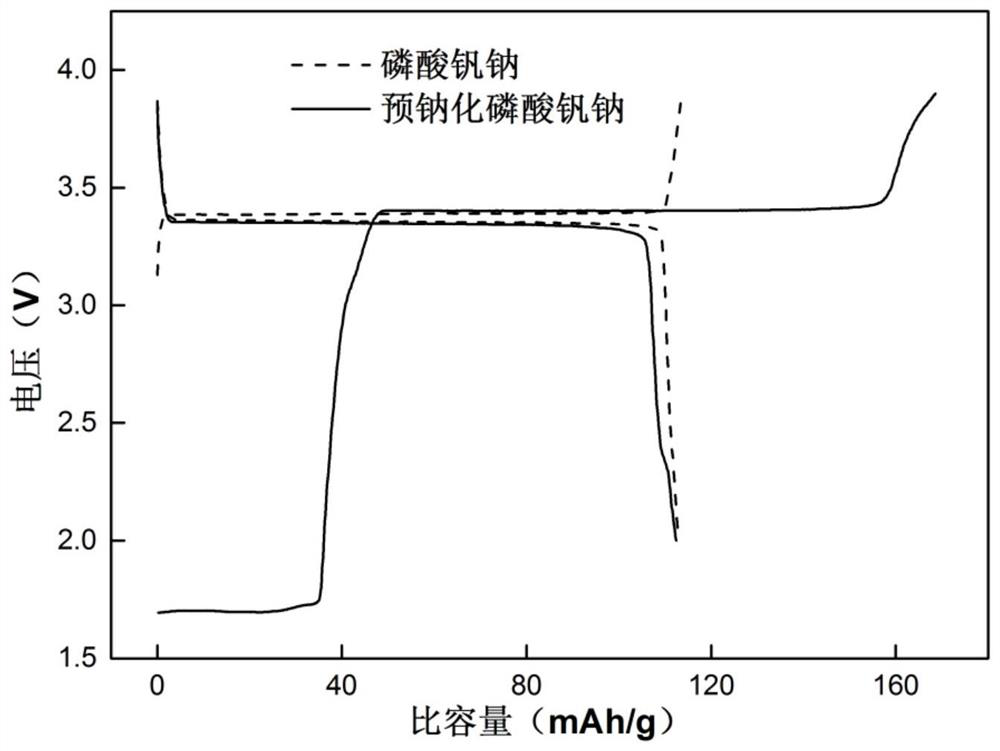

[0033] Na before and after presodiumization 3 V 2 (PO 4 ) 3The electrode is the positive pole, the sodium metal is the negative pole, use 1M NaClO 4 EC / DEC / FEC (v:v:v=10:10:1) electrolyte to assemble half-cells, and conduct charge and discharge tests. The charge-discharge curve of the first week is as follows: image 3 As shown in the figure, it shows that after pre-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com