A boron-doped zinc oxide lamellar ball/p-type pet-ito heterojunction and its preparation method and application

A technology of PET-ITO and zinc oxide, which is applied in the fields of chemical instruments and methods, chemical/physical processes, semiconductor/solid-state device manufacturing, etc., can solve problems such as electrical and photocatalytic properties of B-doped ZnO flake balls that are not mentioned , to achieve the effects of easy control, enhanced built-in electric field, and enhanced electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the boron-doped ZnO flake ball / p-type PET-IEO heterojunction provided by the present invention comprises the following steps:

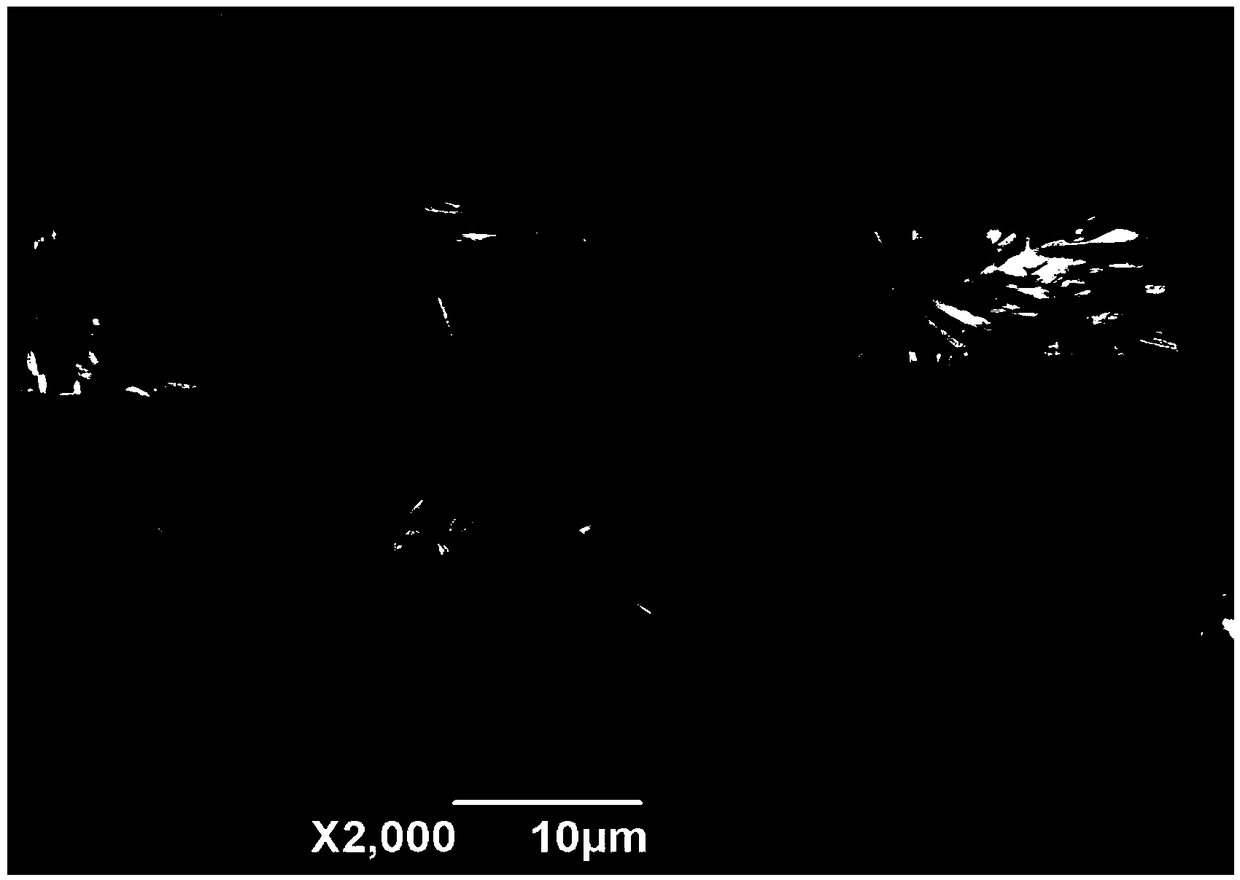

[0029] The first step of flexible substrate preparation: wash with absolute ethanol and deionized water, and air dry.

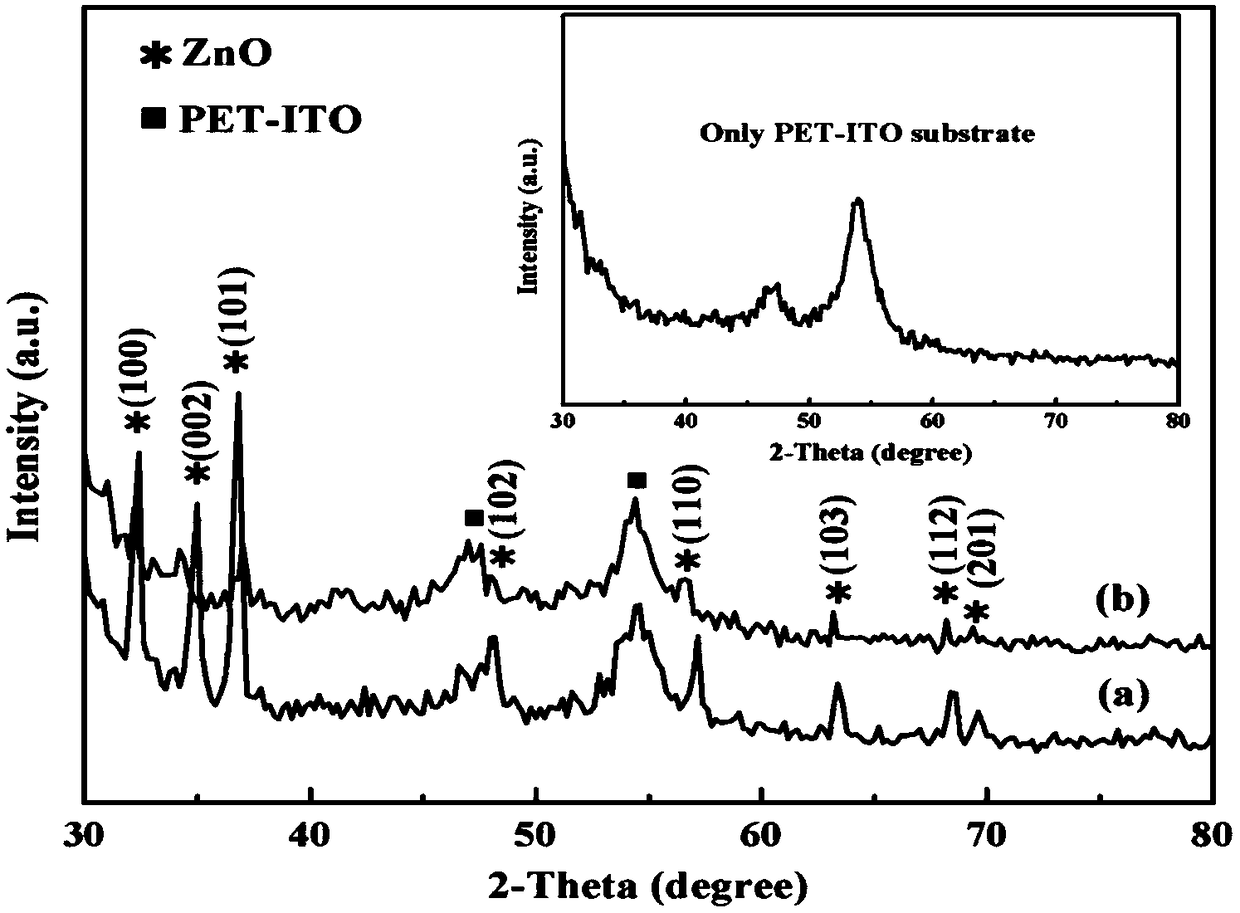

[0030] The second step is to plate the seed layer: use an ion sputtering device (the target is ZnO) to sputter a thin layer of ZnO seed layer on the surface of the flexible substrate PET-ITO, the process parameters are: sputtering time: 3 ~ 5min , Pressure: 8 ~ 10Pa, sputtering current 6 ~ 10mA.

[0031] Preparation of the third step precursor solution: preparation of zinc nitrate hexahydrate (Zn(NO 3 ) 2· 6H 2 0) and urotropine (C 6 h 12 N 4 ) mixed solution, then add H 3 BO 3 solution, and then using a magnetic stirrer to stir for 20 minutes to prepare a precursor solution. Zn(NO 3 ) 2 ·6H 2 O, C 6 h 12 N 4 and H 3 BO 3 The molar ratio of Zn(NO 3 ) 2 ·6H 2 The concentration of O ...

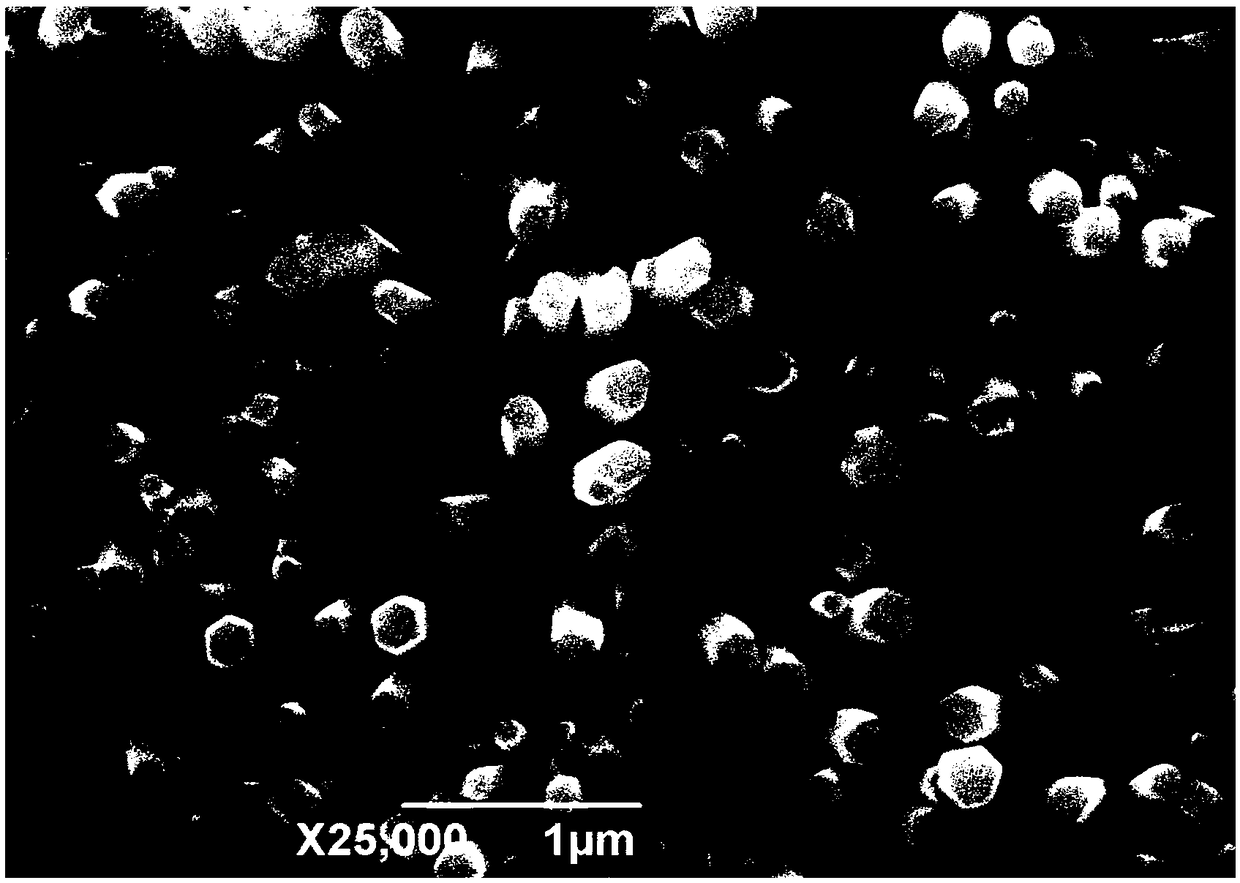

Embodiment 1

[0044] 1) Plating a ZnO seed layer on the surface of the PET-ITO substrate with an ion sputtering coater, the pressure is 10Pa, and the current is 6mA for 1min, and the current is 8mA for 4min;

[0045] 2) Prepare the precursor solution, Zn(NO 3 ) 2 ·6H 2 O, C 6 h 12 N 4 and H 3 BO 3 The molar ratio of Zn(NO 3 ) 2 ·6H 2 O and C 6 h 12 N 4 The molar concentration is 0.05mol / L, H 3 BO 3 The molar concentration is 0.03mol / L, and the magnetic stirrer stirs for 20min;

[0046] 3) Clamp the substrate with the seed layer on the surface with a sample holder and put it vertically into the precursor solution, seal it with a plastic wrap and put it in a drying oven, then raise the temperature to 90°C and keep it at a constant temperature for 5 hours. After cooling down to room temperature naturally, the samples were taken out, rinsed with deionized water, and dried at room temperature.

Embodiment 2

[0048] 1) Plating a ZnO seed layer on the surface of the PET-ITO substrate with an ion sputtering coater, the pressure is 8Pa, and the current is 7mA for 1min, and the current is 9mA for 3min;

[0049] 2) Prepare the precursor solution, Zn(NO 3 ) 2 ·6H 2 O, C 6 h 12 N 4 and H 3 BO 3 The molar ratio of Zn(NO 3 ) 2 ·6H 2 O, C 6 h 12 N 4 and H 3 BO 3 The molar concentration of each is 0.05mol / L, and the magnetic stirrer stirs for 20min;

[0050] 3) Clamp the substrate with the seed layer on the surface with a sample holder and put it vertically into the precursor solution, seal it with a plastic wrap and put it in a drying oven, then raise the temperature to 100°C and keep it at a constant temperature for 4 hours. After cooling down to room temperature naturally, the samples were taken out, rinsed with deionized water, and dried at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com