D-type graphite cast iron containing lead, arsenic and tin

A graphite cast iron, D-type technology, applied in the field of D-type graphite cast iron, can solve the problems of harmful cast iron performance, and achieve the effects of low cost, excellent oxidation resistance and high strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

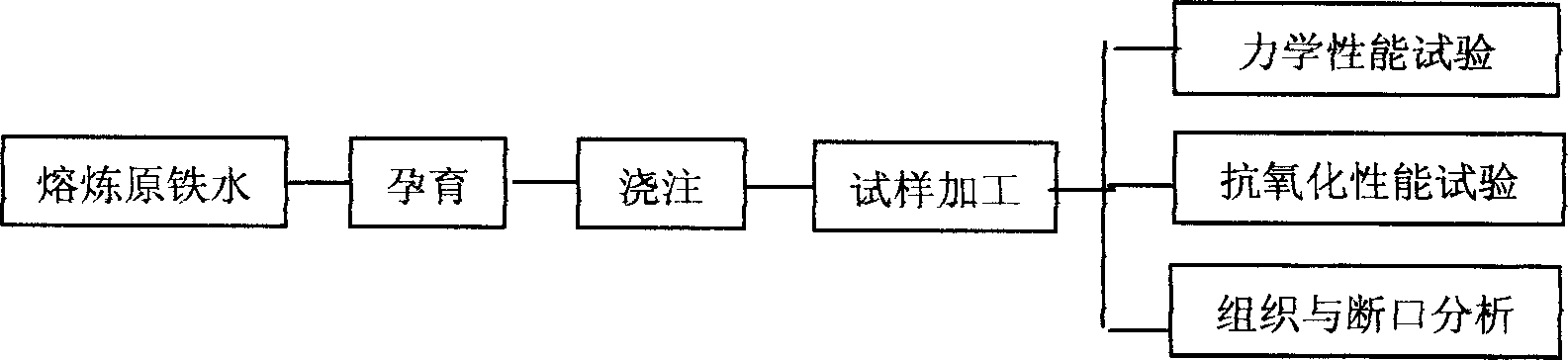

Method used

Image

Examples

Embodiment Construction

[0014] On the basis of studying the dissimilation behavior of lead, arsenic and tin in cast iron, the present invention uses the local pig iron in Fujian Province—Longyan pig iron as the main raw material to smelt molten iron. Adding alloy elements, the chemical composition of the present invention is: 2.9-3.5% C; 2.4-3.6% Si; 0.7-0.9% Mn; ≤0.095% P; ≤0.04% S; 0.003-0.008% Pb; ; 0.08-0.4% Sn; 0.1-0.3% Al; 0.07-0.10% Ti; the rest is Fe. The preparation test of D-type graphite cast iron was carried out in the metal mold. The test uses L 9 (3 4 ) Orthogonal design test method to formulate a plan for research, the four factors are: titanium addition, Si / C, inoculant addition and aluminum addition. Fix the carbon equivalent at the hypoeutectic or eutectic level, change Si / C, and use Longyan pig iron with a powerful inoculant—barium-containing ferrosilicon for effective inoculation, and use the compounding effect of added alloy elements aluminum and titanium , very successfully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com