peo-coated hollow sn-ni alloy nanowire array, its preparation method and its application

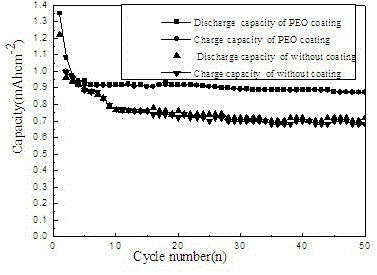

A technology of alloy nano and wire arrays, which is applied in the field of nano materials and its applications, can solve the problems of poor stability and achieve the effect of mild and controllable conditions, good cycle stability and neat arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the PEO-coated Sn-Ni alloy nanowire array of the present invention comprises the following steps:

[0028] 1) Preparation of Ni nanowire arrays by constant current electrodeposition

[0029] a. Treatment of Porous Anodized Aluminum Oxide Template (AAO)

[0030] Cut a copper foil with a diameter of 20 mm and a thickness of 15 μm, and ultrasonically clean it in 1 mol / L dilute hydrochloric acid solution and acetone for 5 min to remove oxides and oil on the surface, and then clean it with deionized water and alcohol Wash them 3-5 times respectively, and dry them under vacuum at 90°C for 4 hours.

[0031] Spray gold on one side of the porous anodized aluminum template, cover the gold-sprayed surface with conductive silver adhesive on the above-mentioned treated copper foil, and seal the part except the AAO template with silica gel to prevent the copper foil from being exposed. After the silica gel solidifies , dried under vacuum at 80°C for 4h.

...

Embodiment 2

[0040]The preparation method of the PEO-coated Sn-Ni alloy nanowire array of the present invention comprises the following steps:

[0041] Step 1) and step 3) are the same as in Example 1.

[0042] Step 2) Preparation of hollow Sn-Ni alloy nanowire arrays by current displacement method

[0043] Put the expanded Ni nanowires into 0.1 M SnSO 4 Soak in the solution for 10 days, take it out, wash it with deionized water and alcohol for 3-5 times, and then dry it in a vacuum oven at 100°C for 8 hours to obtain a hollow Sn-Ni alloy nanowire array.

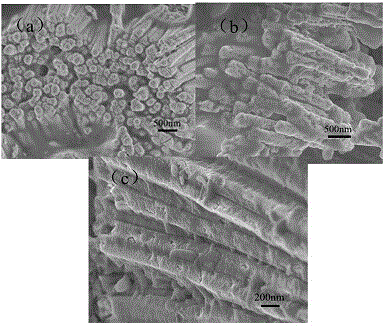

[0044] The array height of the PEO-coated hollow Sn-Ni alloy nanowire array obtained in this example is 8-10um, the distance between two adjacent nanowires is 60-65nm, and the cavity diameter of the hollow Sn-Ni alloy nanowire is 262- 265nm, the thickness of the PEO cladding layer is 15-20nm.

Embodiment 3

[0046] The preparation method of the PEO-coated Sn-Ni alloy nanowire array of the present invention comprises the following steps:

[0047] Step 1) and step 3) are the same as in Example 1.

[0048] Step 2) Preparation of hollow Sn-Ni alloy nanowire arrays by current displacement method

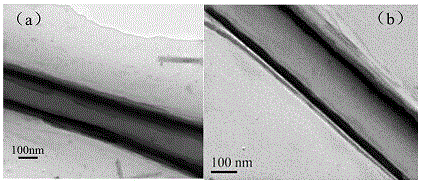

[0049] Put the expanded Ni nanowires into 0.1 M SnSO 4 Soak in the solution for 15 days, take it out, wash it with deionized water and alcohol for 3-5 times, and then dry it in a vacuum oven at 100°C for 8 hours to obtain a hollow Sn-Ni alloy nanowire array. The product obtained in this embodiment is analyzed by transmission electron microscope, and the results are as follows: figure 2 as shown in a.

[0050] The array height of the PEO-coated hollow Sn-Ni alloy nanowire array obtained in this example is 8-10um, the distance between two adjacent nanowires is 60-65nm, and the cavity diameter of the hollow Sn-Ni alloy nanowire is 265- 270nm, the thickness of the PEO cladding layer is 15-20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com