Phenolic resin/coal tar pitch composite-base modified hard carbon negative electrode material and preparation method and application thereof

A technology of phenolic resin and negative electrode material, which is applied in the field of electrochemistry, can solve the problems of solvent ion co-embedding structure, destruction, poor compatibility, etc., and achieve the effect of good electrochemical performance, broad research prospects, and improved rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 100g of phenolic resin, stir and dissolve it in 150mL of absolute ethanol, add 10g of phosphoric acid, and stir for 3 hours to completely dissolve the phenolic resin. In a 500mL beaker, add 50g of coal tar pitch, add washing oil, and dissolve it completely at 180°C, add the above-mentioned modified phenolic resin anhydrous ethanol solution, continue stirring, and pour the self-sealing bag, put into 60°C oven for pre-curing for 10h.

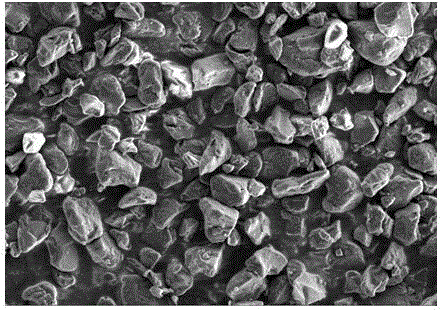

[0032] The pre-cured sample was put into a tube furnace, and carbonized at 800°C for 3h at a heating rate of 3°C / min under an argon atmosphere. The carbonized sample was milled in a ball mill at 400r / min for 10h. Then pass through a 400-mesh sieve to obtain the phenolic resin / coal tar pitch composite base modified hard carbon negative electrode material.

Embodiment 2

[0034] Weigh 100g of phenolic resin, stir and dissolve it in 150mL of absolute ethanol, add 20g of phosphoric acid, and stir for 3 hours to completely dissolve the phenolic resin. In a 500mL beaker, add 100g of coal tar pitch, add washing oil, and dissolve it completely at 180°C, add the above-mentioned modified phenolic resin anhydrous ethanol solution, continue stirring, and pour the self-sealing bag, put into a 60°C oven for pre-curing for 8 hours.

[0035] The pre-cured sample was placed in a tube furnace, and carbonized at 1000°C for 3h at a heating rate of 5°C / min in an argon atmosphere. The carbonized sample was milled in a ball mill at 400r / min for 10h. Then pass through a 400-mesh sieve to obtain the phenolic resin / coal tar pitch composite base modified hard carbon negative electrode material.

Embodiment 3

[0037] Weigh 100g of phenolic resin, stir and dissolve it in 150mL of absolute ethanol, add 20g of phosphoric acid, and stir for 3 hours to completely dissolve the phenolic resin. In a 500mL beaker, add 150g of coal tar pitch, add washing oil, and dissolve it completely at 180°C, add the modified phenolic resin anhydrous ethanol solution prepared above, continue to stir, and pour the self-sealing bag, put into a 60°C oven for pre-curing for 12h.

[0038] The pre-cured sample was placed in a tube furnace, and carbonized at 1200°C for 5h at a heating rate of 5°C / min under an argon atmosphere. The carbonized sample was milled in a ball mill at 600r / min for 6h. Then pass through a 400-mesh sieve to obtain the phenolic resin / coal tar pitch composite base modified hard carbon negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com