High-power non-inductive wire-wound resistor

A wire-wound resistor and high-power technology, which is applied in the field of high-power non-inductive wire-wound resistors, can solve the problems of complex winding process, and achieve the effects of good heat dissipation, low production cost, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

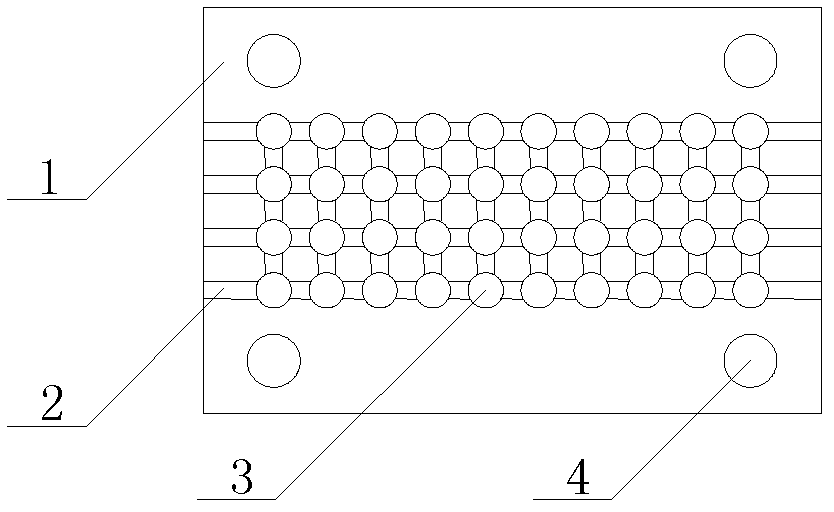

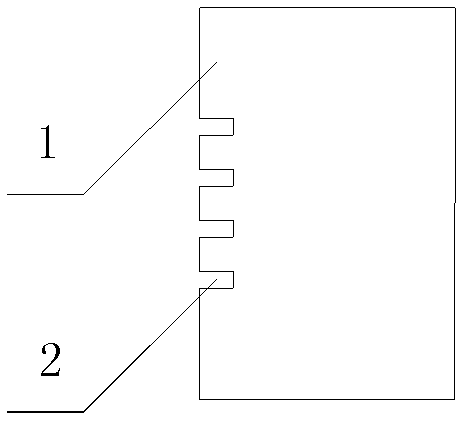

[0034] In this embodiment, the skeleton is made of porcelain material, and the basic skeleton size is 70mm×46mm×12.5mm, in which the threading hole matrix is 4×10, the threading hole diameter is Φ4mm, the wire groove size is 2mm×4mm, and the installation hole is Φ6mm ;

[0035] The size of the auxiliary porcelain tube is Φ5mm×10mm;

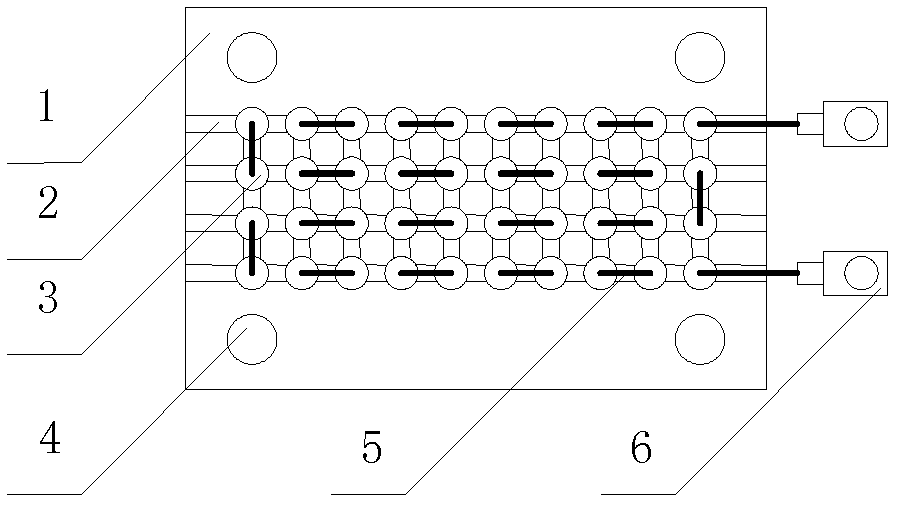

[0036] Among them, the resistance value of the non-inductive high-power fixed resistor is taken as R=11.4186Ω, the resistivity of a single resistance wire is ρ=0.6Ω / m, and the wire diameter of the resistance wire is 1.0mm 2 , utilize formula (1) to calculate resistance wire length L=18m;

[0037] The connection between the resistance wire and the skeleton is realized by the single-wire parallel winding method, such as Figure 3 ~ Figure 5 As shown, the specific method is: connect one end of the resistance wire to the first terminal, use the last hole in the first line of the threading hole array as the initial threading hole, pass the other en...

Embodiment 2

[0041] Another present implementation of the present invention is to apply the wirewound resistor in the BKMJ-JL-Y type passive filter device, and the specific operation is as follows:

[0042] The mounting screw fixes the high-power non-inductive wirewound resistor of the present invention on the bracket of the filter device through the mounting hole, so that the threading hole of the resistor remains vertical. Since the threading hole diameter of the skeleton is larger than the resistance wire diameter, an air duct is formed. , the heat generated by high-power non-inductive wire-wound resistors can be dissipated by air convection. Therefore, an axial fan can be installed under the frame for forced ventilation to increase the rated power of the resistor. The specific method is:

[0043]The model of the axial flow fan is 100FZYZ-5, the distance between the four installation holes is 90X90, the diameter of the axial flow fan installation holes is 6mm, the spacing standard and di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com