Fixture and method for opening oblique holes in steel pipes

A tooling fixture and steel pipe technology, applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of inconvenience, poor manual flame cutting and shape, unsightly appearance of steel pipe openings, etc., to achieve convenient use and improve hole making accuracy. And work efficiency, saving the effect of railing construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

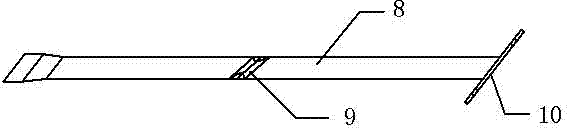

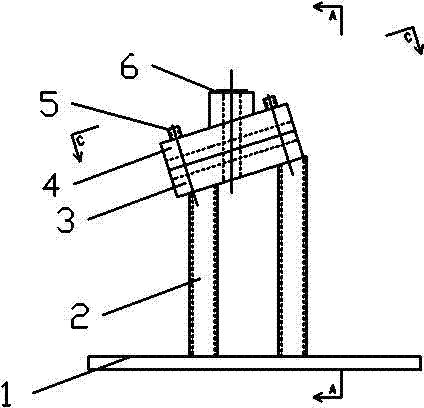

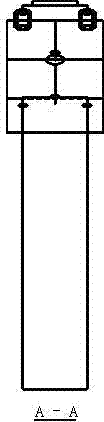

[0035] The tooling fixture for opening inclined holes in steel pipes of the present invention comprises a fixture base 1, two fixture pillars 2, a lower die 3, an upper die 4 and four fastening bolts 5, and is characterized in that:

[0036] The fixture base 1, a steel plate with a thickness of 40mm, is used as the platform plate of the fixture base;

[0037] The two clamp pillars 2 are 18mm channel steels with different lengths and spacing between them, which are respectively perpendicular to the clamp base 1, one end of which is welded and fixed to the clamp base 1, and the other end is arranged as an oblique top;

[0038] The lower mold 3 is a mold with a groove in the middle of the longitudinal direction and a through-hole for drilling in the middle of the groove, and its two ends are welded and fixed to the oblique top ends of the two fixture pillars 2 respectively;

[0039] Described patrix 4, a mold that is provided with groove in the middle of the longitudinal directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com