Single-side edge tooth cutting tool for cylindrical gear

A single gear, side edge technology, applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., can solve the problems of machining accuracy, low machining efficiency, and limited machining range, and reduce environmental pollution. , the effect of improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

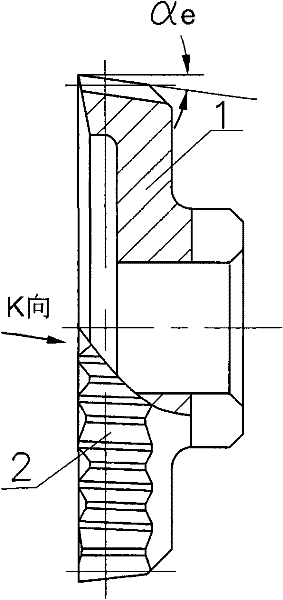

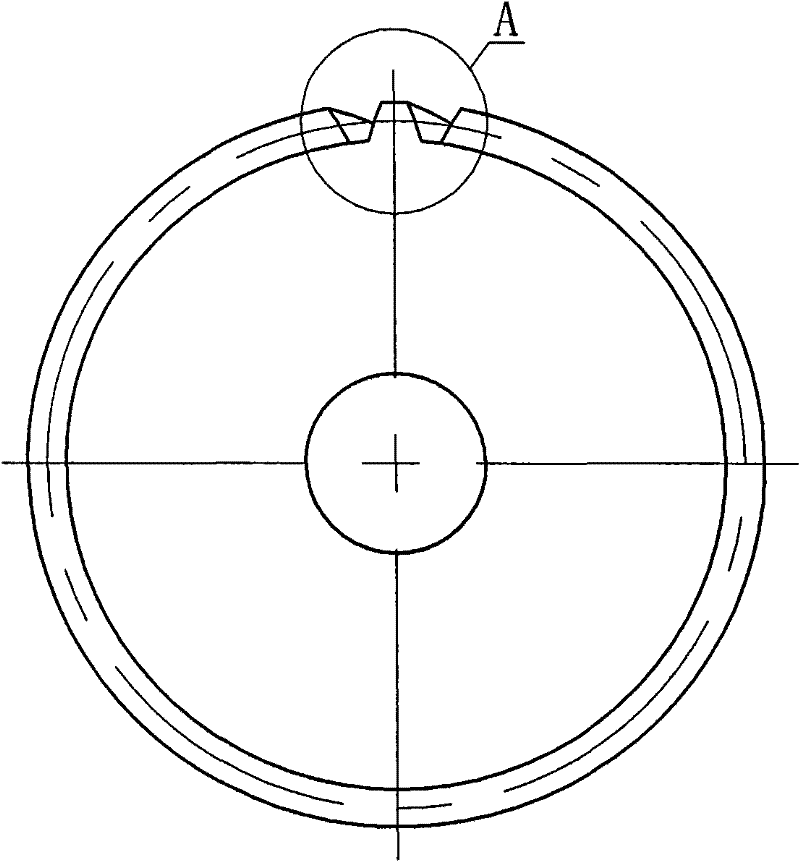

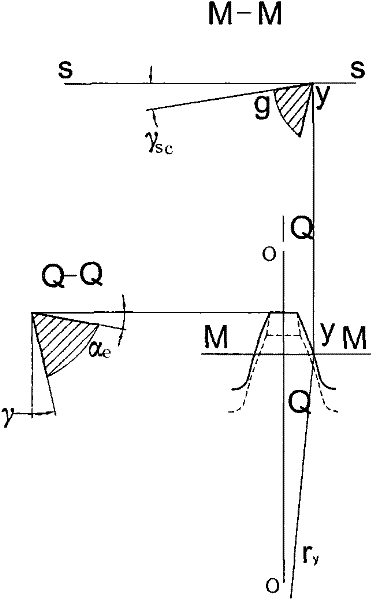

[0017] See Figure 1 to Figure 5 , the profile of cutter of the present invention is similar to gear shape cutter (referring to figure 1 ), including the cutter disc 1, which is provided with a ring of cutter teeth 2 having a conjugate tooth shape with the workpiece gear teeth, and the normal modulus of the cylindrical gear unilateral cutting tool and the normal modulus of the workpiece In the same way, each tooth 2 must have an angle suitable for the cutting state, so each tooth 2 has a rake angle γ and an addendum relief angle α e (see image 3 ), flank relief angle α c (see Figure 5 , r in the figure b0 is the radius of the base circle, r is the radius of the indexing circle, α is the pressure angle, N-N is a straight line passing through the intersection point k of the side edge of the tooth and the indexing circle and tangent to the base circle, parallel to the sectional plane of the tooth disc axis), Index circle helix angle, etc., each tooth 2 also has a side edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com