Preparation method of protective tape

A technology for protecting tapes and adhesives, applied in the direction of adhesives, film/flake adhesives, adhesive types, etc. problems, to achieve the effect of less environmental pollution, excellent followability, and good adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

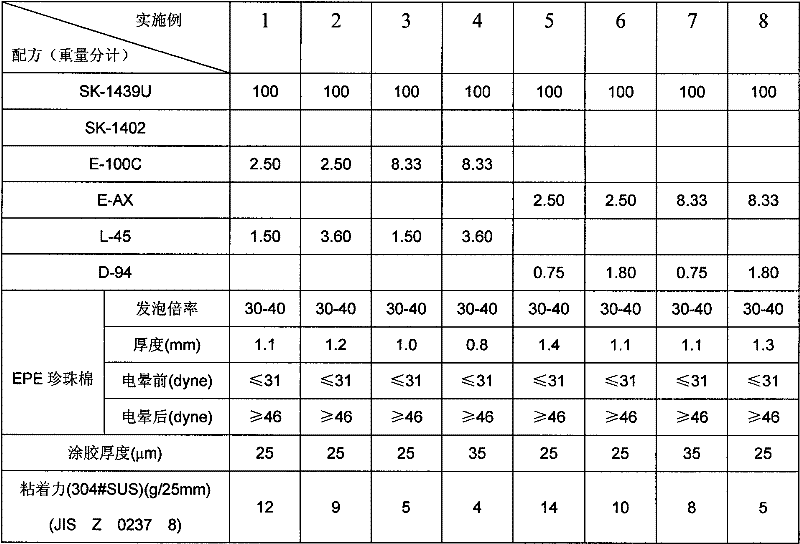

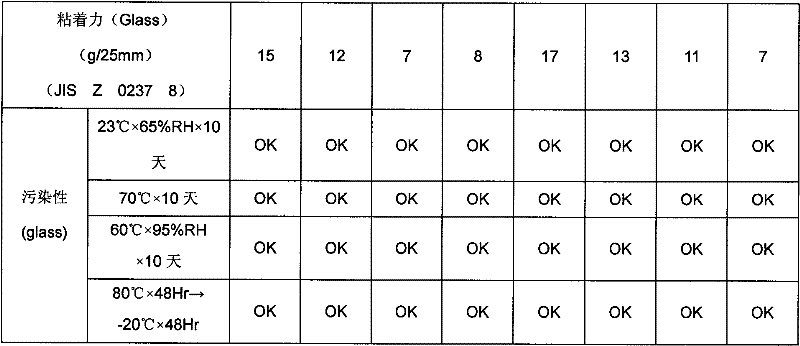

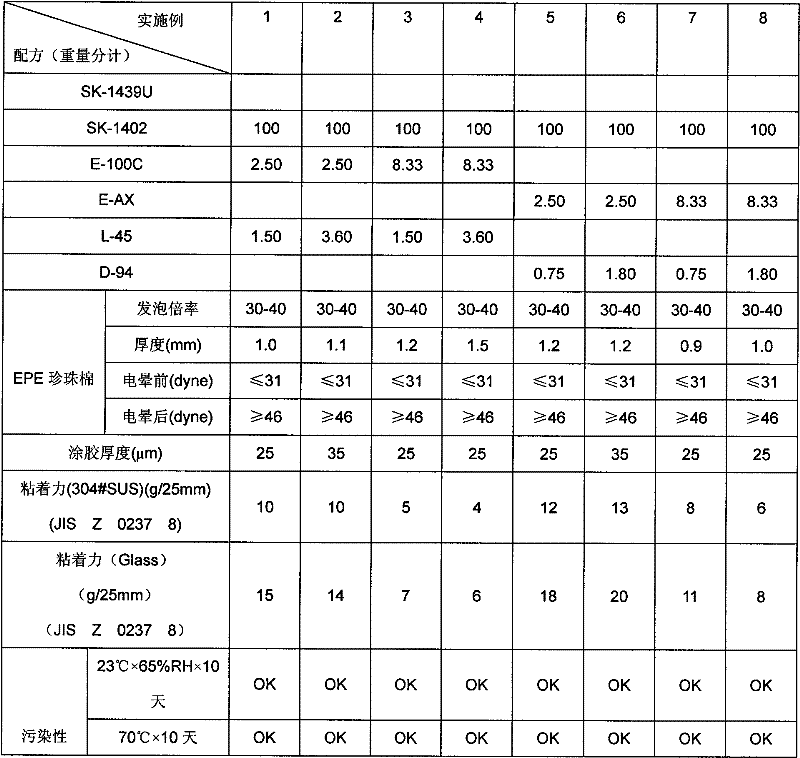

[0019] Below in conjunction with embodiment the present invention is described in further detail.

[0020] The preparation method of protective tape, comprises the steps:

[0021] ①Using EPE pearl cotton as the base material, corona is carried out on the surface of the base material, so that the surface tension of the base material is ≥46 dynes, and the corona conditions are preferably as follows: corona power 1.0KW~2.0KW, running speed 10m / min;

[0022] ② Apply an acrylate adhesive on the surface of the substrate as an adhesive layer, the thickness of the adhesive layer is 20 μm to 35 μm, and the acrylate adhesive is added with an epoxy-based hardener and an isocyanate-based hardener;

[0023] ③Dry, take up the finished product from the back, and ripen it to get the protective tape.

[0024] The addition amount of the epoxy-based hardener is 2.50-8.33, and the addition amount of the isocyanate-based hardener is 0.75-1.80, and the above-mentioned addition amount is based on 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com