Composite seal coat for pavement maintenance

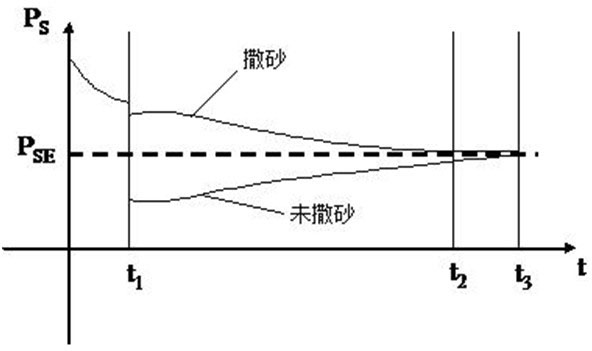

A technology of material layer and sand material, which is applied in the field of composite sealing layer for pavement maintenance, can solve the problems of easy loosening and peeling of stone materials, threats to driving safety, poor adhesion, etc., and achieve good spreading effect, long-term anti-skid ability, and adhesion Lego effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

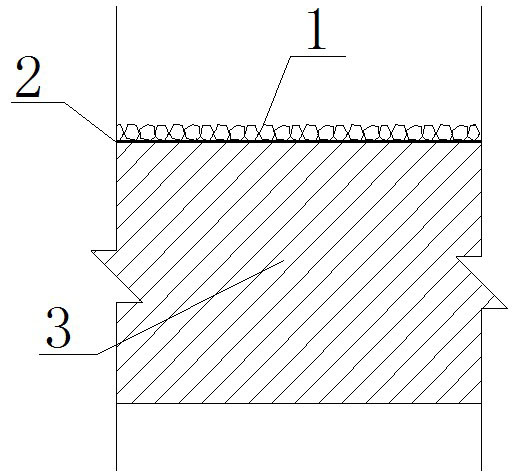

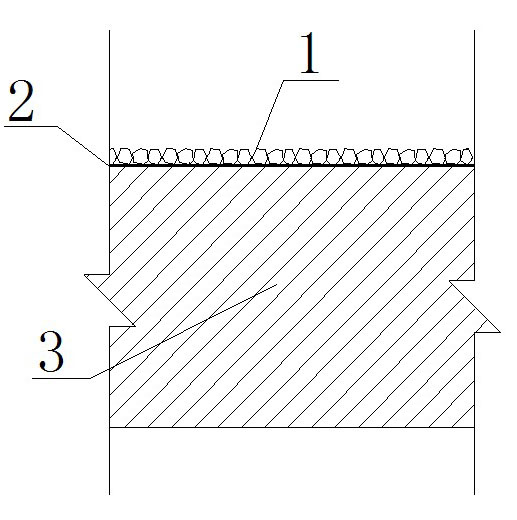

[0028] Below in conjunction with accompanying drawing, the present invention will be further introduced. The emulsified asphalt material used in the present invention is NDAP (Non-reachable Fog Seal), which is a cationic polymer modified asphalt coating. The evaporation residue content of the modified emulsified asphalt material is greater than 55%, and the standard viscosity of asphalt is 15-40. The extension is greater than 40cm.

[0029] Before the construction of the sealing layer, the original pavement surface needs to be cleaned to remove road debris.

[0030] For sealing layer construction, use asphalt sprayer to spray emulsified asphalt material. The spraying amount is controlled in the range of 0.4-0.7L / ㎡. The optimal amount is determined according to the actual road surface structure depth. Generally, the original road surface structure depth is about 0.9mm and 0.5L / ㎡ is selected. amount of asphalt.

[0031] During the construction of the sealing layer, the sprayin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com