Method for constructing concrete chimney cylinder body through formwork lifting process

A formwork and chimney technology, which is applied in the field of concrete chimney cylinder construction by the formwork lifting method, can solve the problems that the concrete does not have molding strength, high construction technical requirements, and large manpower investment, and achieves good appearance quality, easy assembly, quality and The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

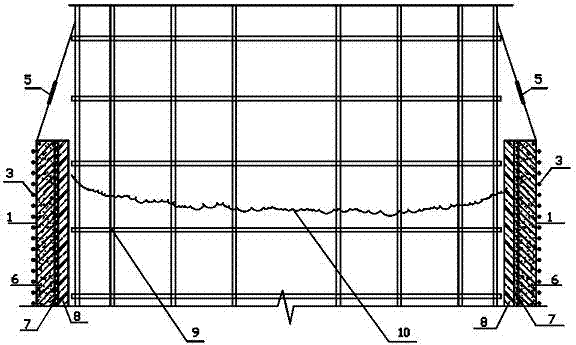

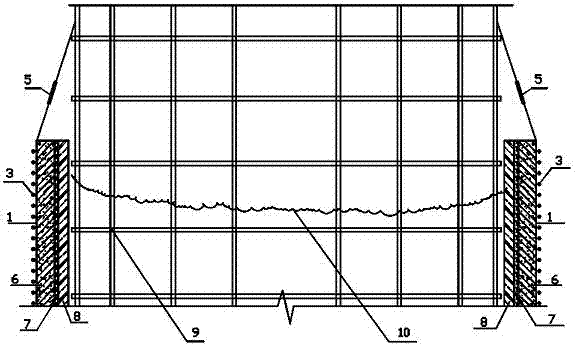

[0018] The construction method provided by the present invention is specifically described below in conjunction with accompanying drawing, and this construction method is specifically as follows:

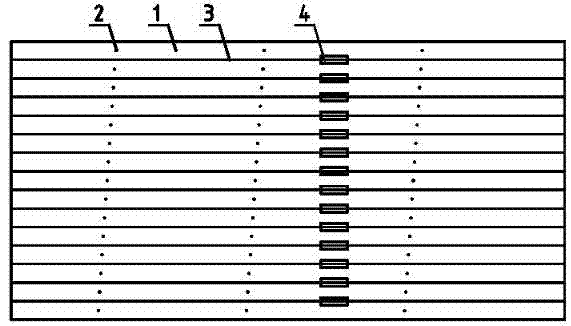

[0019] Use 2mm galvanized iron sheets to make formwork 1, with a height of 1.50m; calculate the number of iron sheets required according to the circumference of the chimney wall, and use 5mm screws 2 to connect the 2mm galvanized iron sheets at a distance of 100mm above and below to form a formwork with the same outer diameter as the chimney wall 1. Fix 8mm steel wire rope 3 outside the formwork 1 as the outer hoop. The distance between the lower half of the outer hoop steel wire rope 3 is 50mm, and the distance between the upper half is 80mm; The wire is used as a rope buckle to fix the steel wire rope, and the rope buckle is spaced 1000mm along the circumferential direction, and a wire tensioner 4 is installed at the end of each steel rope to be used for adjusting the tightness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com