Buffer and air-conditioner using same

A buffer and cavity technology, which is applied in the field of air conditioners with buffers, can solve the problems of strong vibration of the throttling part of the pipeline, aggravated the degree of eddy current and turbulent flow in the pipeline, and large fluctuation of pressure pulsation, so as to improve the flow rate. condition, reduce eddy current turbulence phenomenon, improve the effect of fixed frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

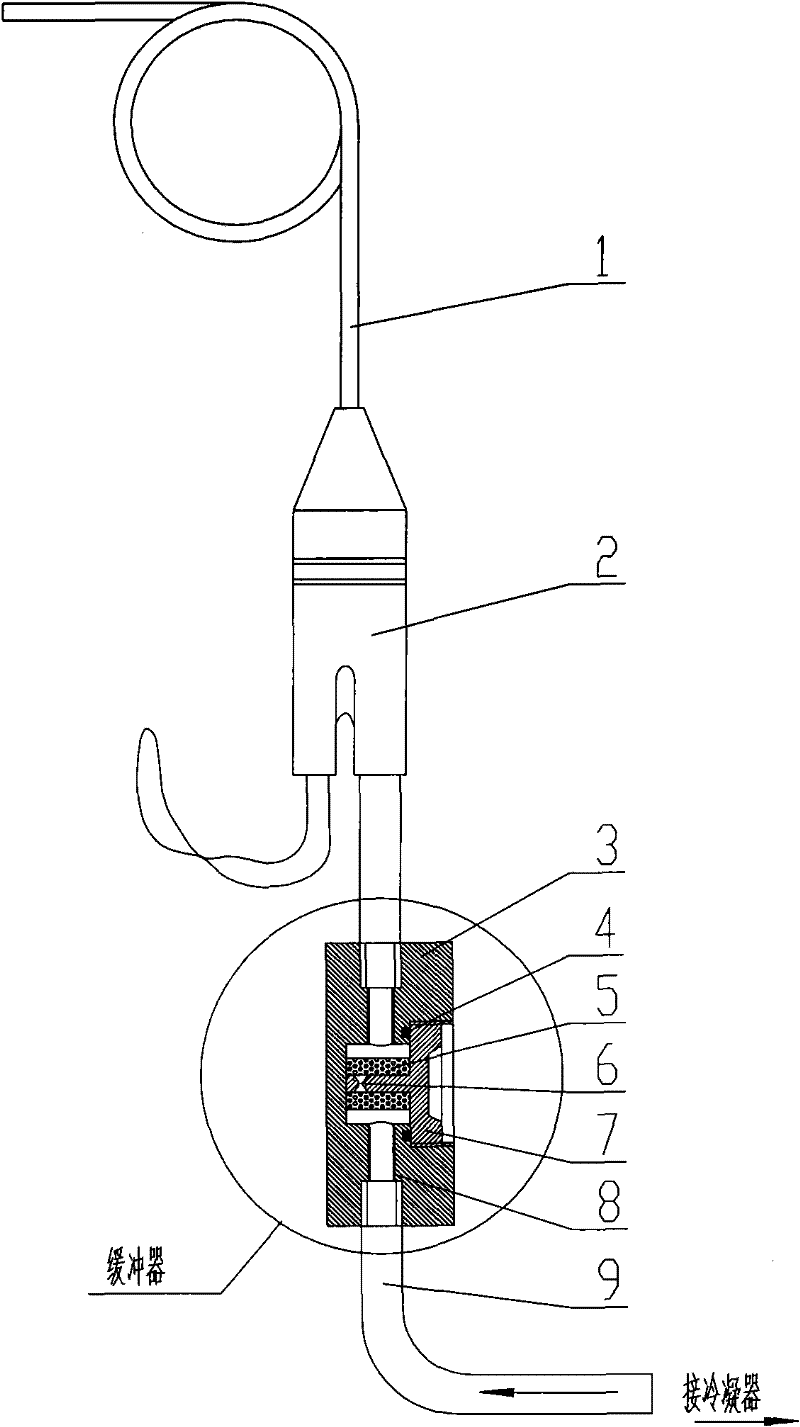

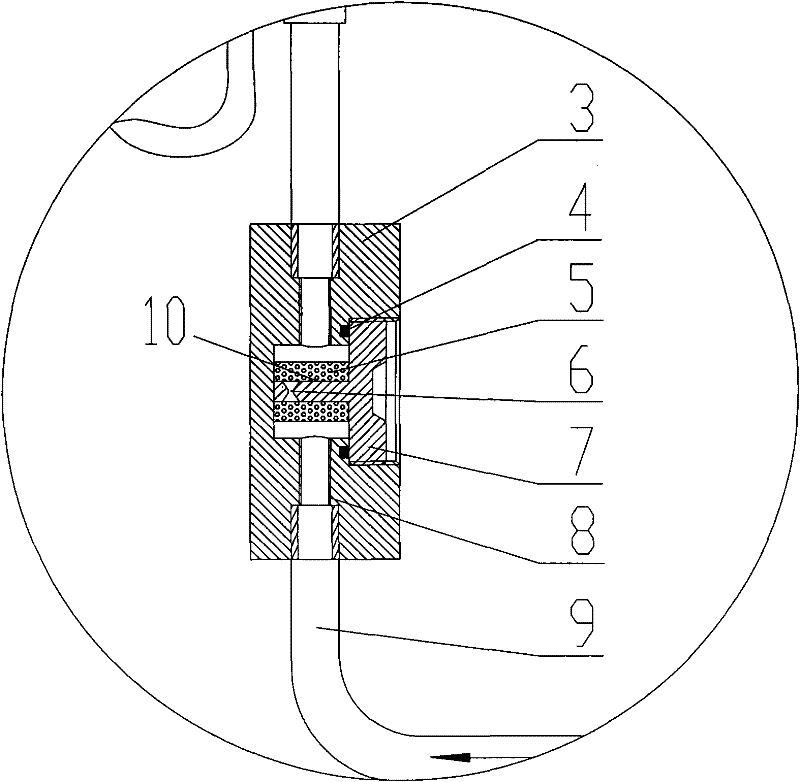

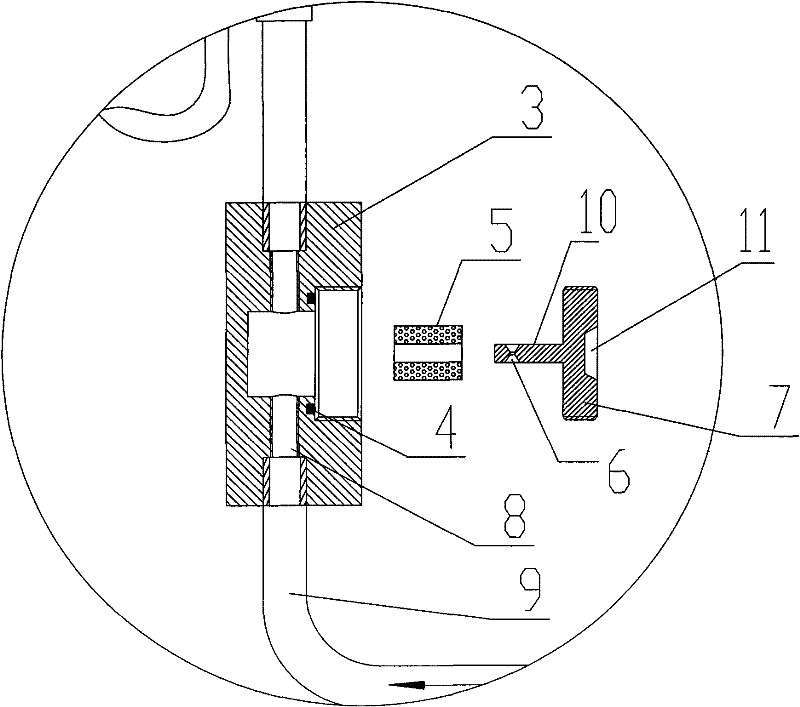

[0026] see figure 1 , the lower part of the buffer is connected to the air conditioner condenser through an L-shaped tube 9, and the upper part is connected to the differential device 2 through a 30 mm long copper tube with an outer diameter of 7 mm. The tubes are eventually connected to the evaporator, the evaporator is connected to the compressor by the return gas pipe, and the compressor discharge pipe is connected to the condenser.

[0027] When the air conditioner is working, under the forced push of the compressor, the high-temperature and high-pressure refrigerant gas enters the condenser, and is forced to cool by the fan, and the cooled liquid refrigerant is released from the condenser. figure 1 The L-shaped tube 9 shown in the figure enters the buffer, and after the buffering effect, the refrigerant flows smoothly, and then enters the capillary tube 1 through the differential device 2, and the throttling and step-down refrigerant enters the evaporator from the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com