Flush type bearing failure intelligent diagnosing device based on ARM (advanced RISC machine) and DSP (digital signal processor)

A fault diagnosis device and embedded technology, applied in the direction of mechanical bearing testing, etc., can solve the problem that the signal spectrum characteristics cannot be reflected, and achieve the effect of improving accuracy, realizing portability and friendly interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

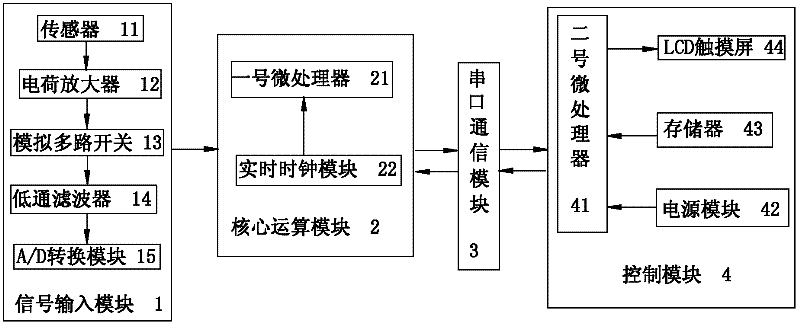

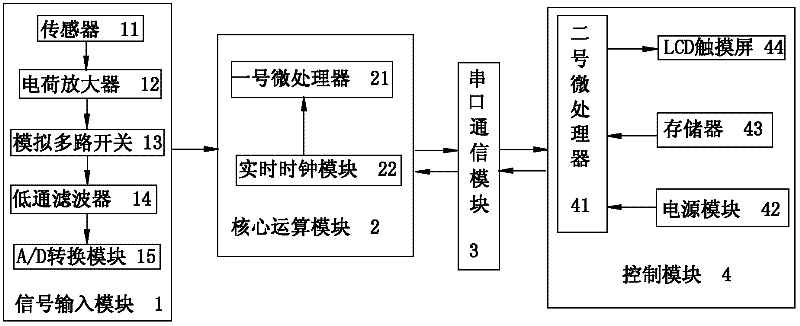

[0015] Such as figure 1 As shown, an embedded bearing fault intelligent diagnosis device based on ARM and DSP of the present invention includes a signal input module 1 , a core computing module 2 , a serial communication module 3 and a control module 4 . The input end of the signal input module 1 is connected to the tested bearing, the output end of the signal input module 1 is connected to the core operation module 2 , and the core operation module 2 is connected to the control module 4 through the serial communication module 3 .

[0016] The signal input module 1 transforms the vibration signal of the bearing into a suitable digital signal and inputs it to the No. 1 microprocessor 21 in the core operation module 2 . Signal input module 1 comprises sensor 11, charge amplifier 12, analog multi-channel switch 13, low-pass filter 14 and A / D convers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com