Double-layer phase change resistance and forming method thereof as well as phase change memory and forming method thereof

A phase change memory and phase change resistor technology, applied in electrical components and other directions, can solve the problems of difficult opening process and small critical dimensions, and achieve the effects of reducing reset current, small critical dimensions, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

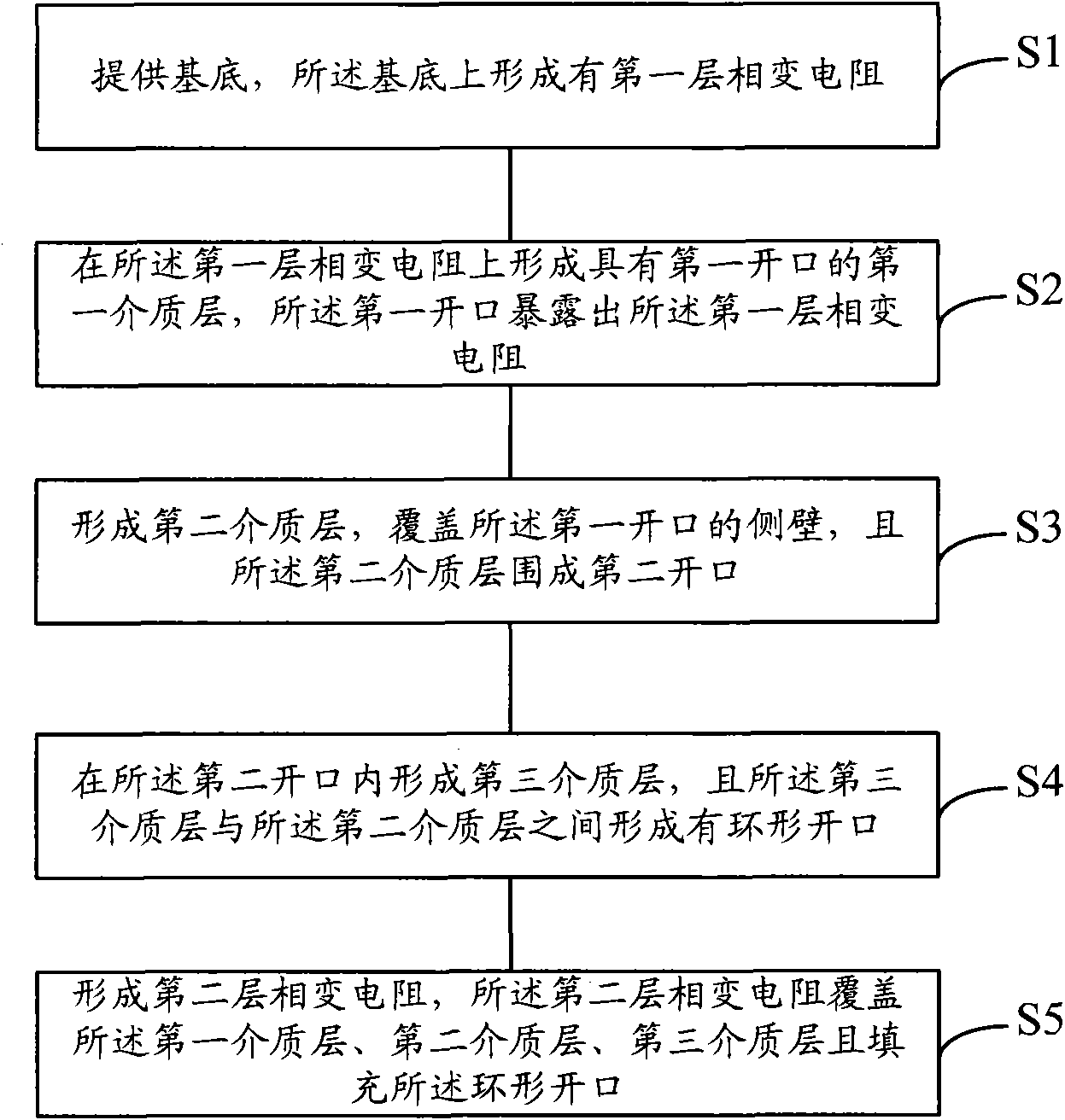

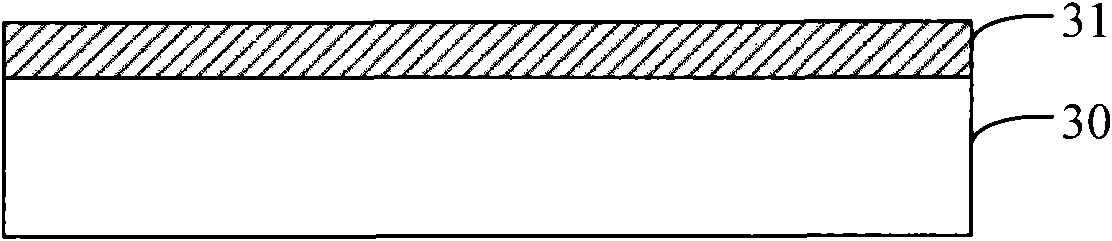

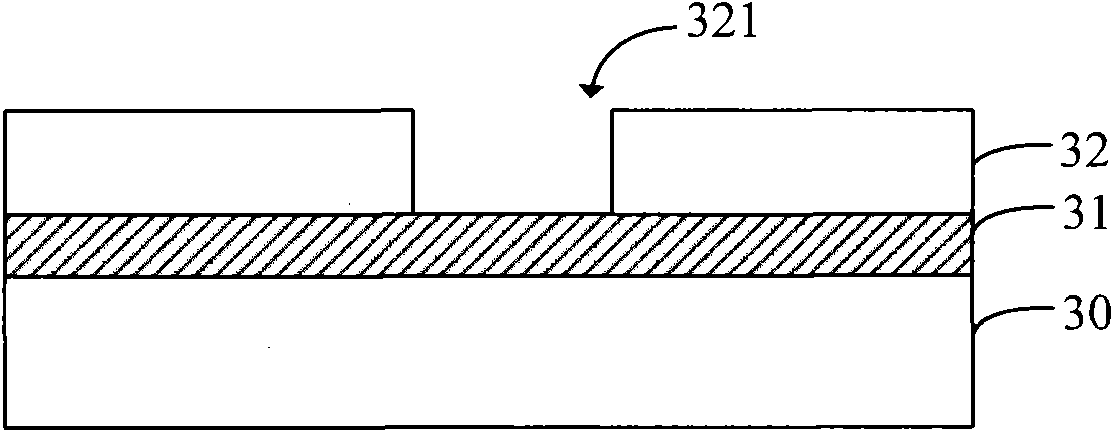

[0034] In the method for forming a double-layer phase change resistor according to the specific embodiment of the present invention, a first dielectric layer with a first opening is formed on the first layer of phase change resistor, and a second dielectric layer is formed on the sidewall of the first opening. The dielectric layer surrounds the second opening; a third dielectric layer is formed in the second opening, and an annular opening is formed between the third dielectric layer and the second dielectric layer; a second layer of phase change resistance is formed to cover the The first dielectric layer, the second dielectric layer and the third dielectric layer fill the annular opening. The phase-change resistors filled in the openings are the connection between the phase-change resistors of the second layer and the phase-change resistors of the first layer. By this method, it is easy to form a small ring-shaped opening with a critical size, so that the phase-change resisto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com