Microwave heating energy-feedback antenna and manufacturing method thereof

An energy-feeding antenna and microwave heating technology, applied in microwave heating and other directions, can solve the problems of high electric field strength, materials that are easy to ignite and discharge, and overheating, and achieve the effects of suppressing discharge and improving microwave power output efficiency and coupling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

[0049] The microwave heating feeding antenna of the present invention is used to connect with the waveguide to radiate microwave energy.

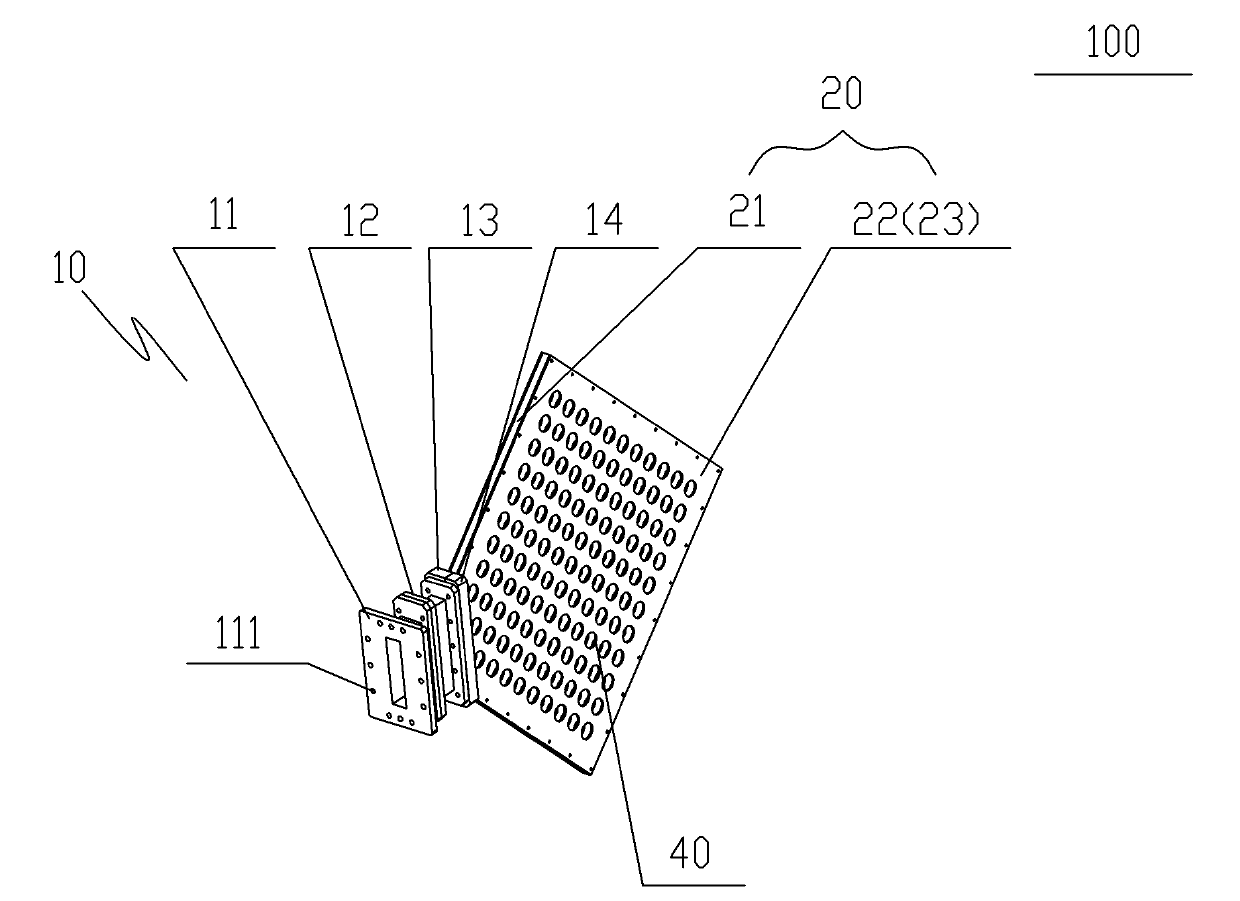

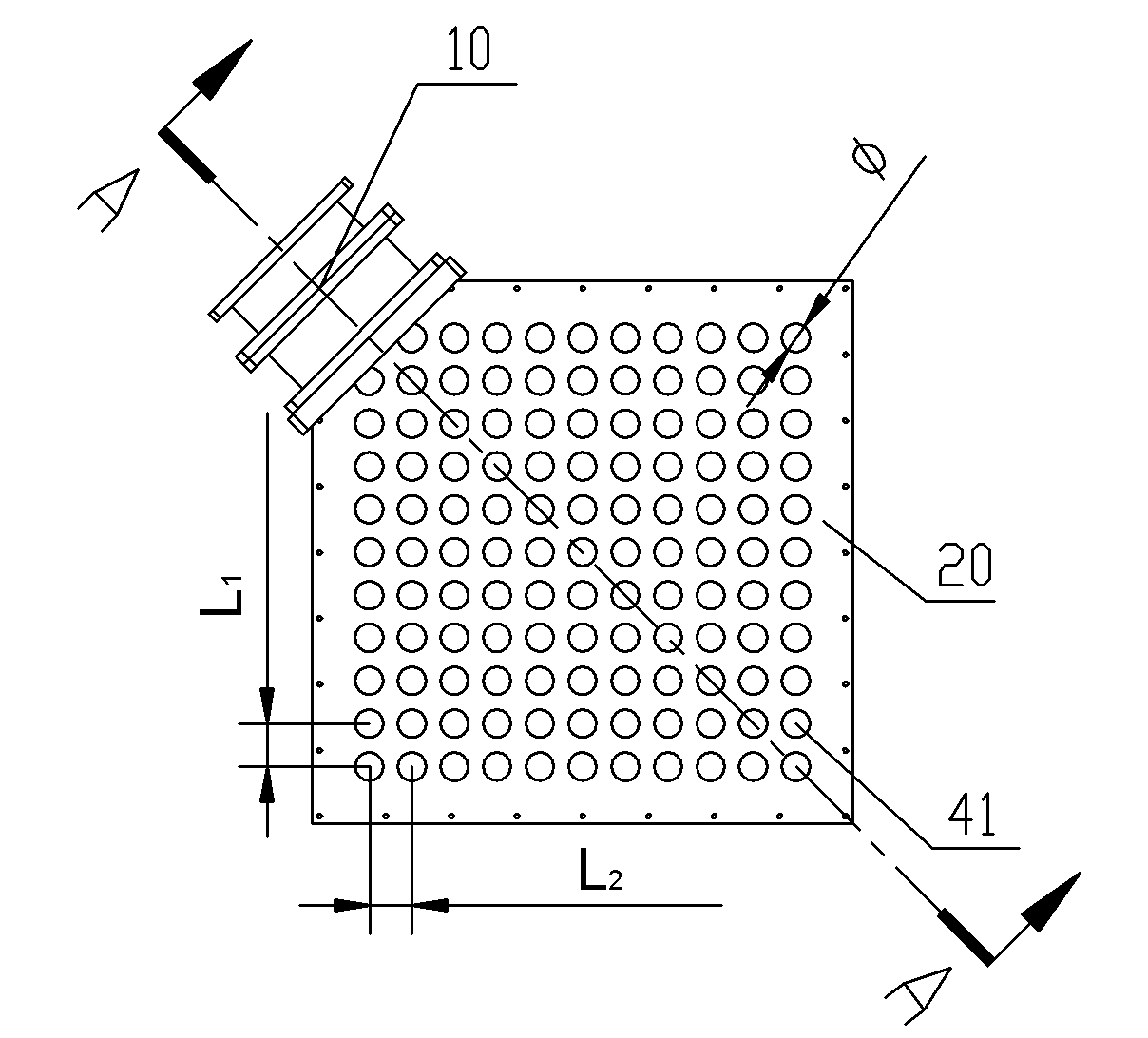

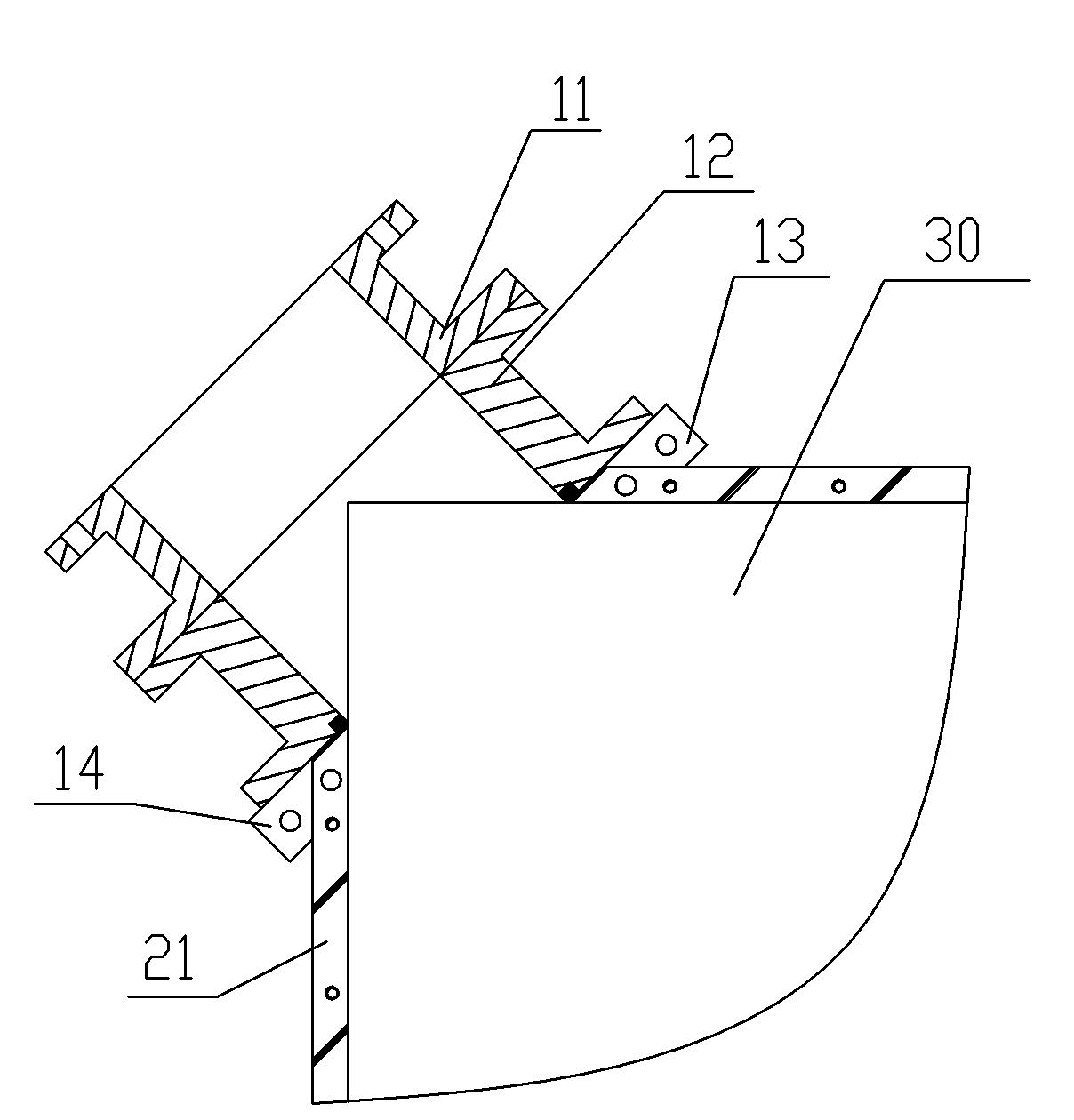

[0050] Such as figure 1 As shown, the microwave heating feeding antenna 100 includes a waveguide flange 10, a resonant cavity 20, a sealing medium layer arranged in the cavity of the resonant cavity 20 and filling the entire cavity, and a microwave The hole array 40 that radiates out of the resonant cavity, wherein the waveguide flange 10 is located on a corner of the resonant cavity 20, and the excitation angle between the waveguide and the resonant cavity is 45°, such as when the resonant cavity 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com