Inductor of eddy currents for magnetic tape testing and scanner based thereon

An eddy current induction and magnetic tape testing technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as the limitation of sensitivity tape testing resolution capability, increase effective resistance, etc., and achieve the effect of reducing inductive impedance, improving response, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

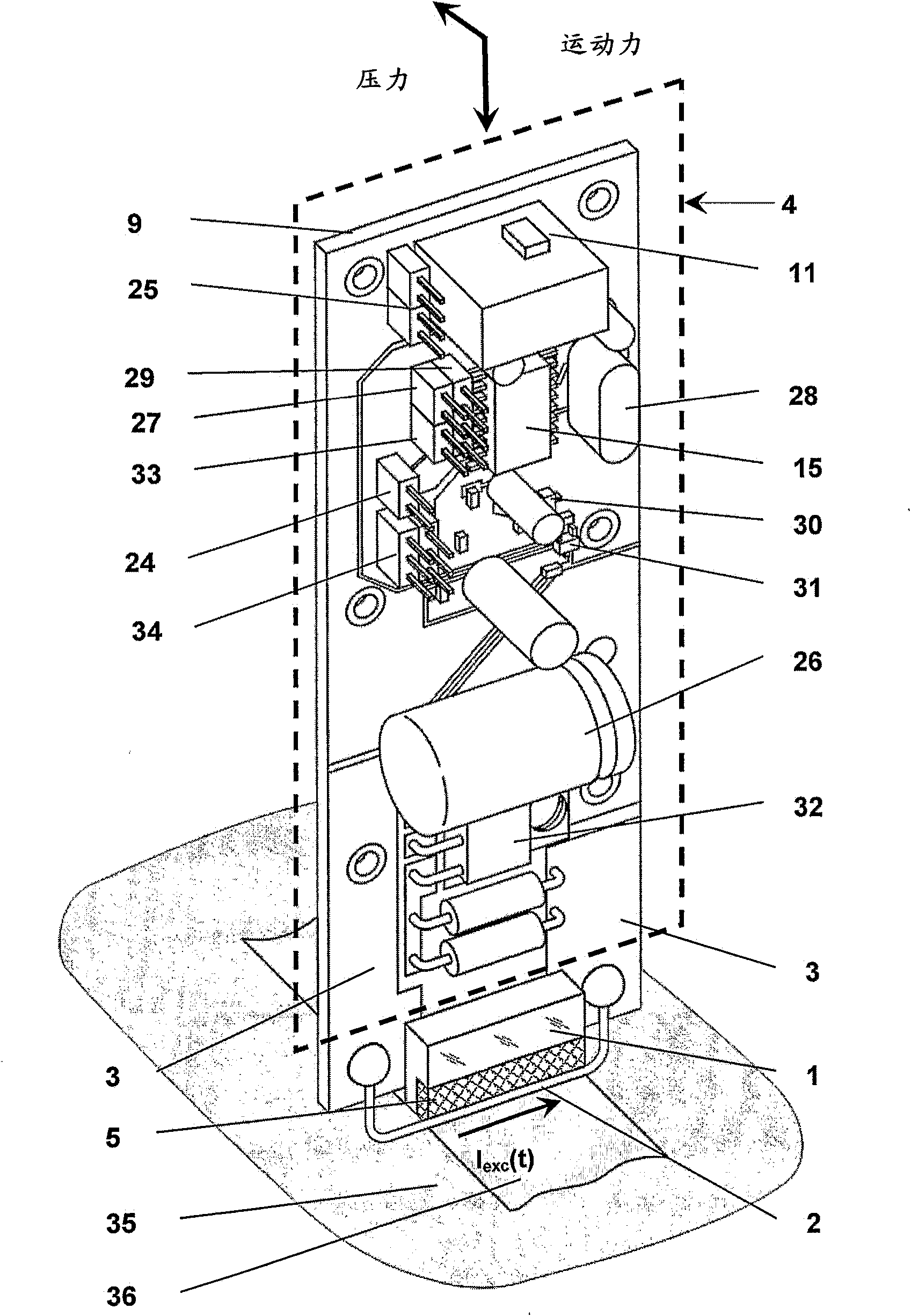

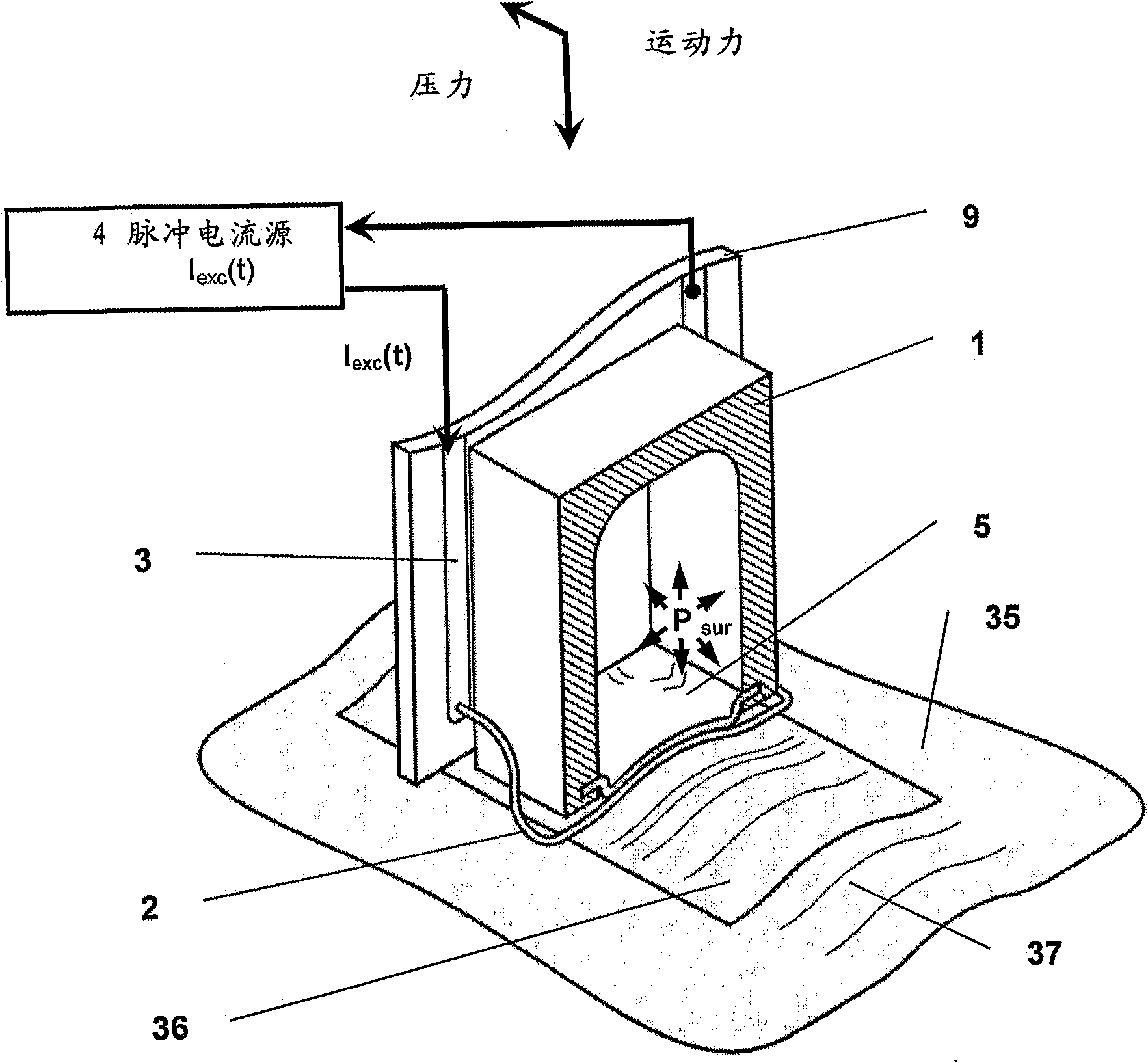

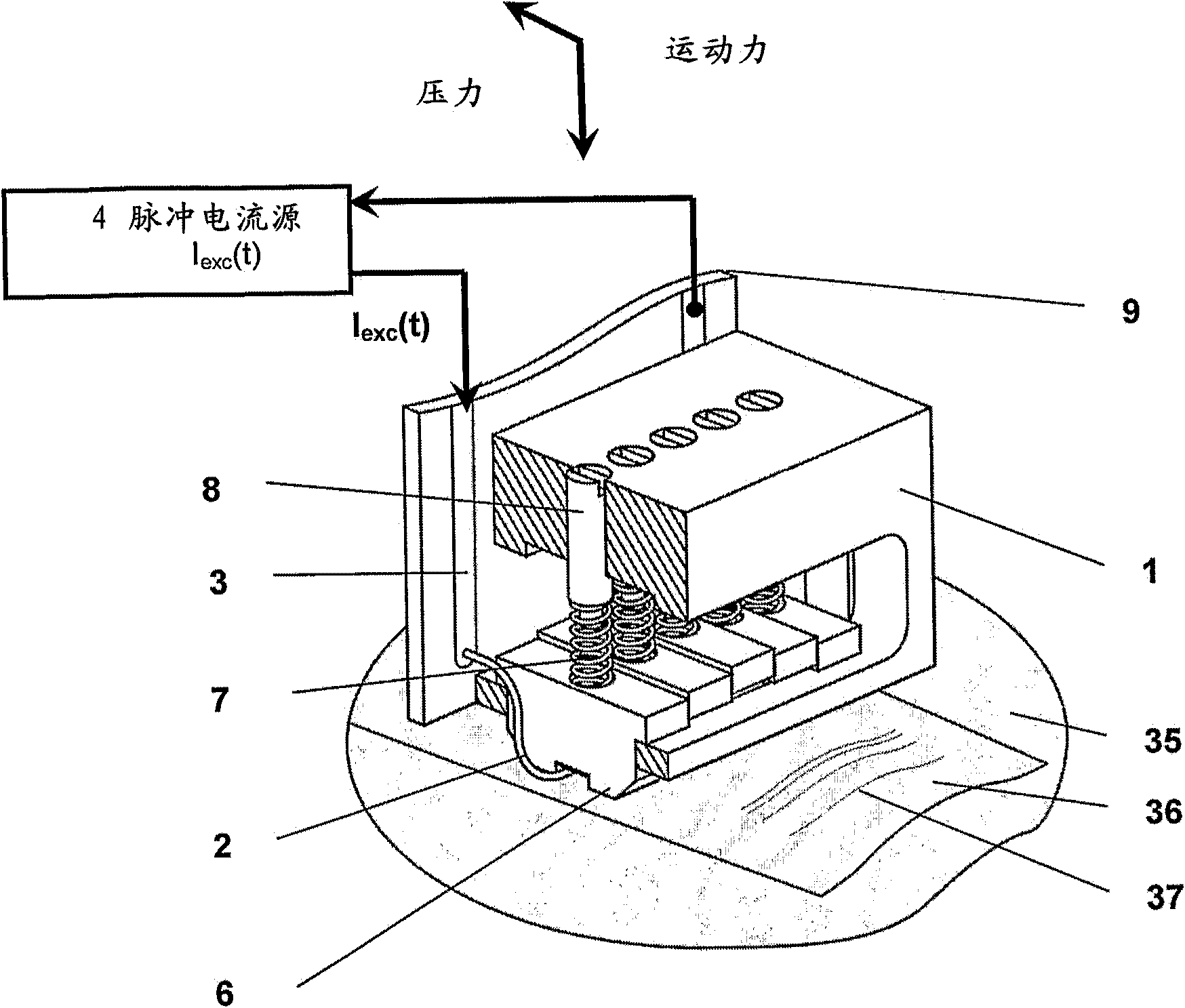

[0078] Each embodiment of the proposed eddy current inductor for magnetic tape testing (see Figure 1-3 )include:

[0079] non-ferromagnetic medium support element 1, which has an unmarked longitudinal groove at the operable flat end,

[0080] A preferably flexible field conductor 2 (for example, a copper or other wire segment with a diameter preferably in the range of 0.3 mm to 0.8 mm, or a ribbon twisted from at least two wire segments which may have different diameters and chemical compositions, or other suitable flexible electrical conductor segment), which is disposed in said groove, and

[0081] Suitable means (eg conductor paths) 3 for connecting said conductor 2 to said pulsed current source 4 .

[0082] In the simplest case (see figure 1 ), the non-ferromagnetic dielectric support element 1 is formed in a single plate, the excitation conductor 2 rests on the bottom of said groove via a support spacer 5 made of elastic dielectric material.

[0083]The monolithic pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap