Adhesive tape ore rock-discharge system on-line dry separator

A dry separator and tape technology, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of waste of resources, mixing of ore into rocks, and difficulty in separating all rocks and ore, so as to achieve uniform material thickness and avoid problems. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

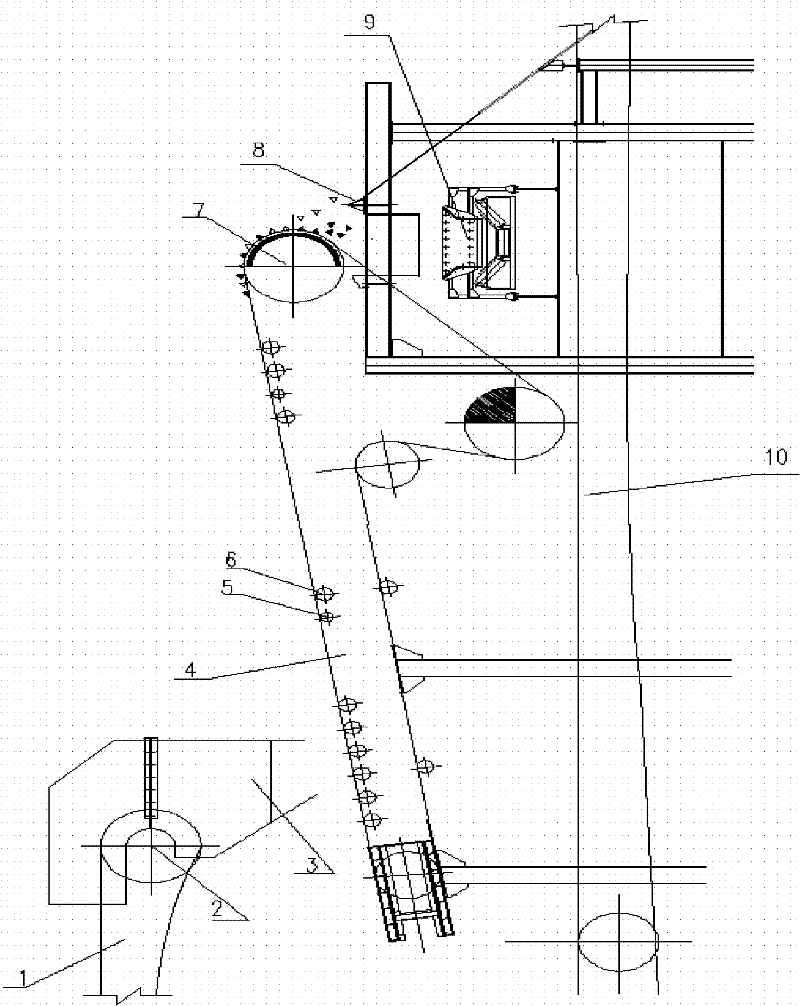

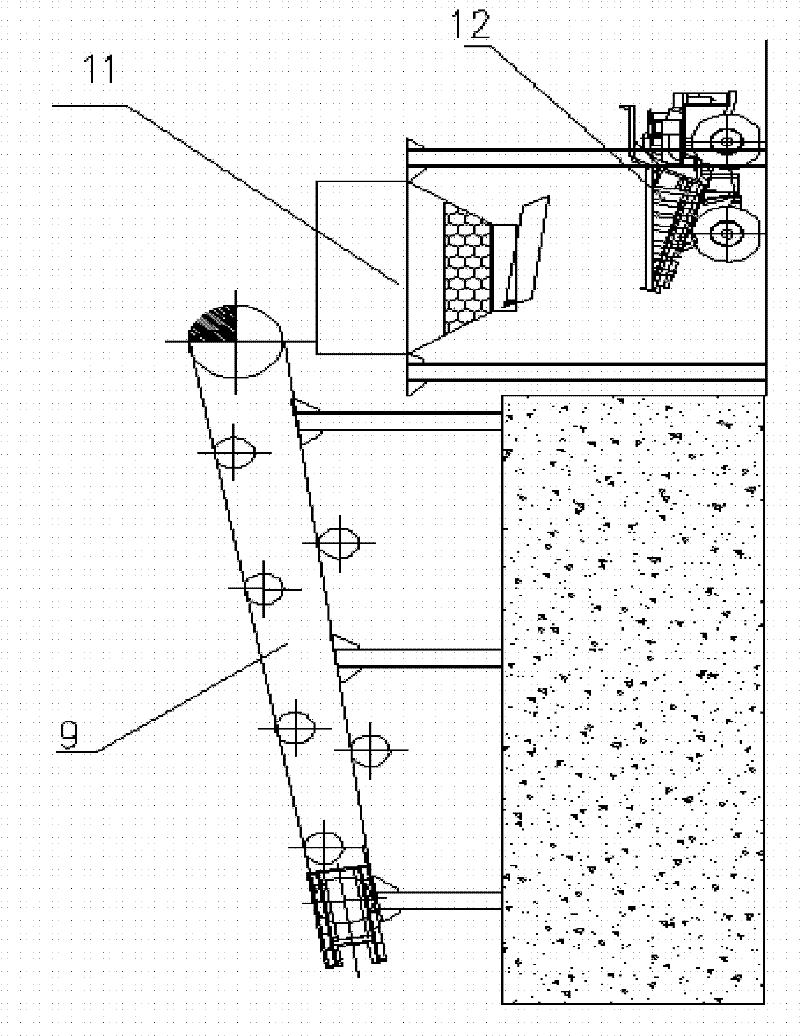

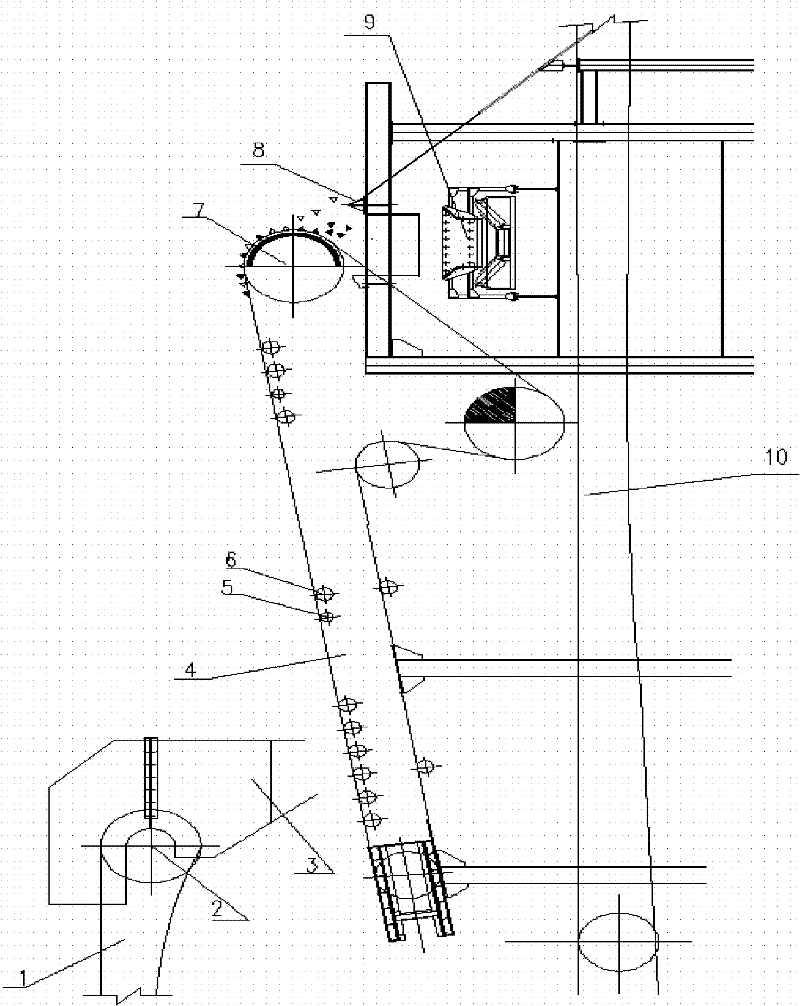

[0018] The present invention comprises the mechanical body of the dry separator; the automatic control part of the dry separator; the centralized control part of the dry separator. Sorting to realize the separation of ore and rock. The automatic control part of the dry separation machine adopts on-site control, and the dry separation is controlled by control cables, power cables, magnetic declination regulators, pull rope switches, deviation switches, and material level gauges. The operation of the system and whether the dry separation equipment is used for ore separation. The centralized control part of the dry separation machine is installed in the computer in the centralized control room, which is integrated with the rock removal system through the PLC control system to realize centralized control and centralized operation.

[0019] 1. Design and manufacture the mechanical part of the online dry separation machine for the rock removal system, which is mainly divided into tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com