Wood treatment preparation and preparation method

A technology of wood treatment and preparation, which is applied in the direction of wood impregnation, impregnated wood, wood processing utensils, etc., and can solve problems such as unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

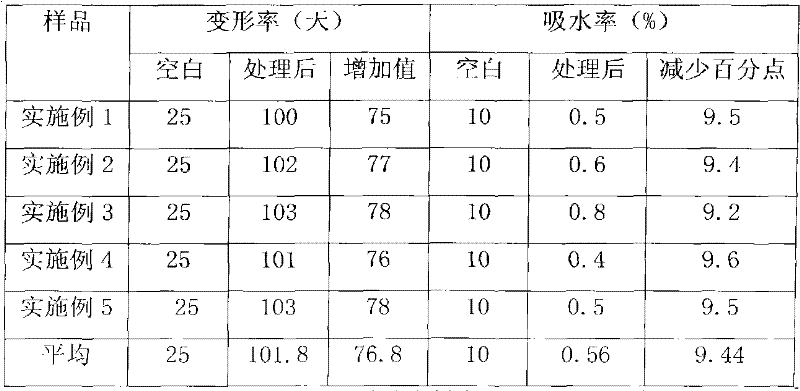

Examples

Embodiment 1

[0024] 20% macromolecule oxidized wax A28 (produced by SASOL company in South Africa);

[0025] 13% EVA resin 910 (produced by Korea Hyundai);

[0026] 6% stearic acid 1800 (Tianjin Zhongshengtai Chemical Co., Ltd.);

[0027] 9% sodium dodecylbenzenesulfonate (produced by Shanghai Shengzhong Fine Chemical Co., Ltd.);

[0028] 1% sodium benzoate (produced by Tianjin Dongda Chemical Co., Ltd.);

[0029] 0.1% camphor oil (produced by Ji'an Guoguang Perfume Factory);

[0030] Distilled water remaining.

[0031] Macromolecule oxidized wax A28 (produced by SASOL company in South Africa), EVA resin 910 (produced by Hyundai Co., Ltd. in South Korea), stearic acid 1800 (produced by Tianjin Zhongshengtai Chemical Co., Ltd.), camphor oil (produced by Guoguang Perfume Factory in Ji'an City) according to embodiment 1 The proportioning amount is added to a stainless steel container and slowly heated to 126±5°C for 30±5 minutes to make an oil phase material, the surfactant is added to di...

Embodiment 2

[0033] 10% macromolecule oxidized wax A28 (produced by SASOL company in South Africa);

[0034] 13% No. 85 microcrystalline wax (produced by Nanyang Paraffin Fine Chemical Factory);

[0035] 10% petroleum resin p115 (produced by Idemitsu Corporation of Japan);

[0036] 5% EVA resin 910 (produced by Korea Hyundai);

[0037] 7% stearic acid 1800 (Tianjin Zhongshengtai Chemical Co., Ltd.);

[0038] 3% morpholine (produced by Wuhan Kaitong Fine Chemical Co., Ltd.);

[0039] 9% Pingpingjia A-20 (produced by Fushun Konka Chemical Co., Ltd.);

[0040] 0.1% camphor oil (produced by Ji'an Guoguang Perfume Factory);

[0041] 1.5% ammonium benzoate (produced by Wuhan Organic Xinkang Chemical Co., Ltd.);

[0042] Distilled water remaining.

[0043] Polymer oxidized wax A28 (produced by South Africa SASOL company), microcrystalline wax (produced by Nanyang Paraffin Fine Chemical Factory), EVA resin 910 (produced by Hyundai Corporation of South Korea), stearic acid 1800 (produced by T...

Embodiment 3

[0045] 12% macromolecule oxidized wax A28 (produced by SASOL company in South Africa);

[0046] 13% No. 80 petroleum microcrystalline wax (produced by Nanyang Paraffin Fine Chemical Factory);

[0047] 10% EVA resin 910 (produced by Korea Hyundai);

[0048] 7% petroleum resin p115 (produced by Idemitsu Corporation of Japan);

[0049] 8% stearic acid 1800 (Tianjin Zhongshengtai Chemical Co., Ltd.);

[0050] 2% morpholine (produced by Wuhan Kaitong Fine Chemical Co., Ltd.);

[0051] 4% Pingpingjia A-20 (produced by Fushun Konka Chemical Co., Ltd.);

[0052] 02% camphor oil (produced by Ji'an Guoguang Perfume Factory);

[0053] 15% ammonium benzoate (produced by Wuhan Organic Xinkang Chemical Co., Ltd.);

[0054] Distilled water remaining.

[0055] Polymer oxidized wax A28 (produced by South Africa SASOL company), microcrystalline wax (produced by Nanyang Paraffin Fine Chemical Factory), EVA resin 910 (produced by Hyundai Corporation of South Korea), stearic acid 1800 (produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com