Dental selective laser sintering 3D printing wax powder and preparation method thereof

A laser sintering and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of insufficient data collection accuracy and rapid prototyping processing accuracy, less wax powder, poor molding accuracy, etc., to meet the needs of laser sintering, low kinematic viscosity, good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

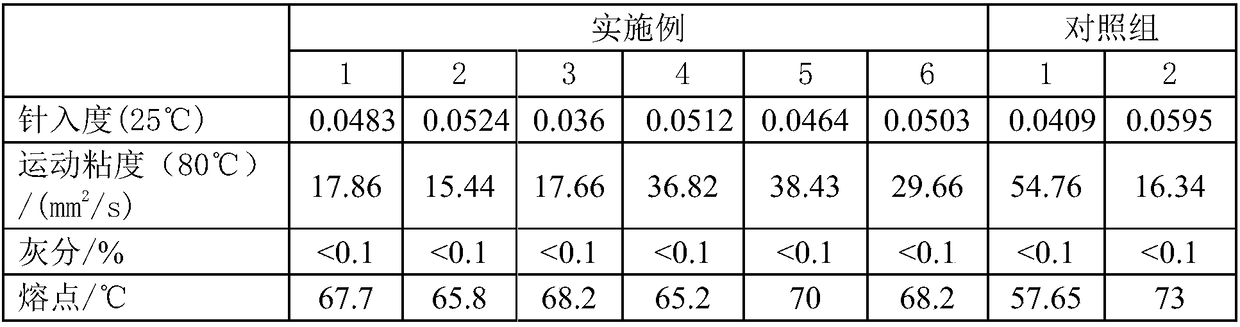

Examples

Embodiment 1

[0042] A dental selective laser sintering 3D printing wax powder, prepared by the following method: 682# microcrystalline wax (42%), 58# fully refined wax (remainder, about 14.5%), PE wax (4%) , S wax (15%), Carabba wax (21%), color paste (3‰), put it into a 100°C reaction kettle and heat and stir. After all the substances melt, continue to heat and stir for 30min, release, cool, and then use powder Machine pulverization obtains mixed wax A. Put the mixed wax A in a low-temperature cooling device to cool to -190 ° C, mechanically pulverize it into powder, then stir in a mixer, and gradually spray sodium dodecylbenzenesulfonate (5%, the surfactant is first dissolved in an organic solvent ), through a 300-mesh sieve after vacuum drying to obtain the basic wax powder B.

[0043] Put the basic wax powder B in the double-cone mixer, and then add octadecyldimethyl quaternary ammonium nitrate (5‰), ultraviolet absorber uv-9 (5‰), antioxidant 1010 (3‰) ‰), mixed evenly and passed th...

Embodiment 2

[0046]A dental selective laser sintering 3D printing wax powder, prepared by the following method: 70# microcrystalline wax (57%), EVA (remainder, about 5%), ozokerite (18.5%), refined montan wax (19.5%) Color paste (3‰), put it into a 100°C reaction kettle and heat and stir. After all the substances are melted, continue to heat and stir for 30 minutes, release, cool, and then pulverize with a powder machine to obtain mixed wax A. Put the mixed wax A in a low-temperature cooling device to cool to -190°C, mechanically crush it into powder, then stir in a mixer, and gradually spray sodium dodecylbenzenesulfonate (6.5‰, the surfactant is first dissolved in an organic solvent ), through a 300-mesh sieve after vacuum drying to obtain the basic wax powder B.

[0047] Put the basic wax powder B in the double-cone mixer, and then add octadecyldimethyl quaternary ammonium nitrate (5‰), ultraviolet absorber uv-9 (4.5‰), antioxidant 1010 (4.5‰) ‰), mixed evenly and passed through a 300-...

Embodiment 3

[0050] A dental selective laser sintering 3D printing wax powder, prepared by the following method: 58# fully refined wax (14.5%), 682# microcrystalline wax balance (about 31.5%), EVA (4%), beeswax (10.5%), ozokerite (10%), carabba wax (29.5%), color paste (3 ‰), put it into a 100 ℃ reaction kettle and heat and stir, continue to heat and stir for 30min after all the substances are melted, release, cool, Then pulverize with a powder machine to obtain mixed wax A. Put the mixed wax A in a low-temperature cooling device to cool to -190°C, mechanically crush it into powder, then stir in a mixer, and gradually spray sodium dodecylbenzenesulfonate (8‰, the surfactant is first dissolved in an organic solvent ), through a 300-mesh sieve after vacuum drying to obtain the basic wax powder B.

[0051] Put the basic wax powder B in the double-cone mixer, and then add octadecyldimethyl quaternary ammonium nitrate (5‰), ultraviolet absorber uv-9 (5‰), antioxidant 1010 (3‰) ‰), mixed evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com