Cooling filter tip, heat-not-burn cigarette and application

A mouth stick and tobacco section technology, applied in the field of application, cooling mouth stick and heat-not-burn cigarettes, can solve the problems of affecting the smoking experience and the taste, so as to improve the smoking taste, reduce the temperature of the smoke, and reduce the smoke Effect of air inlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

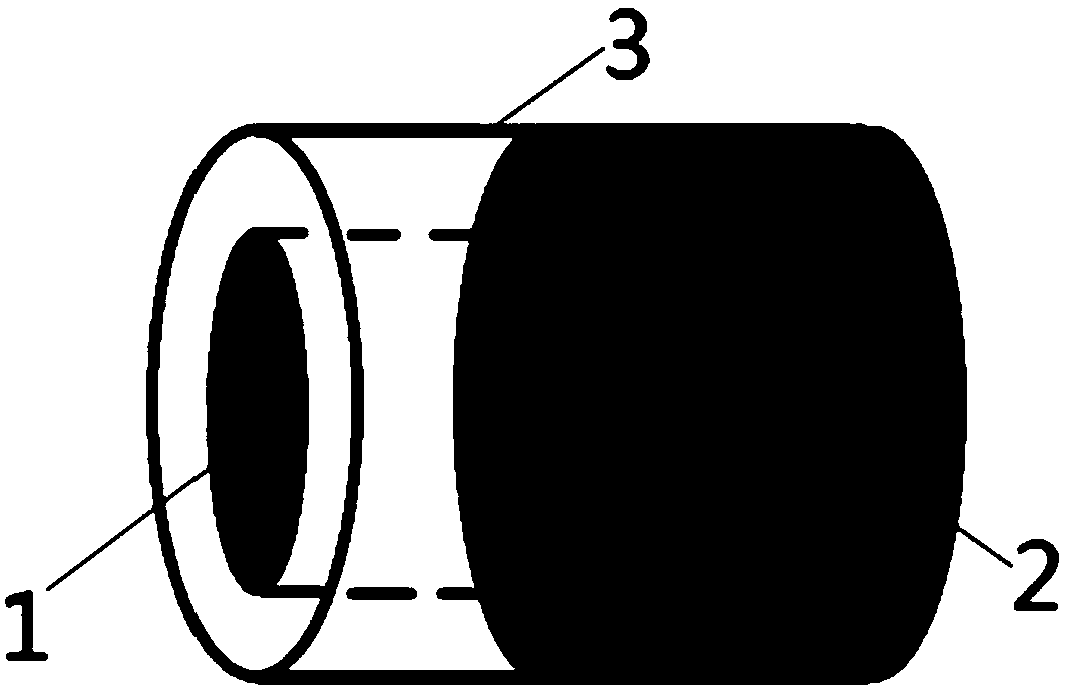

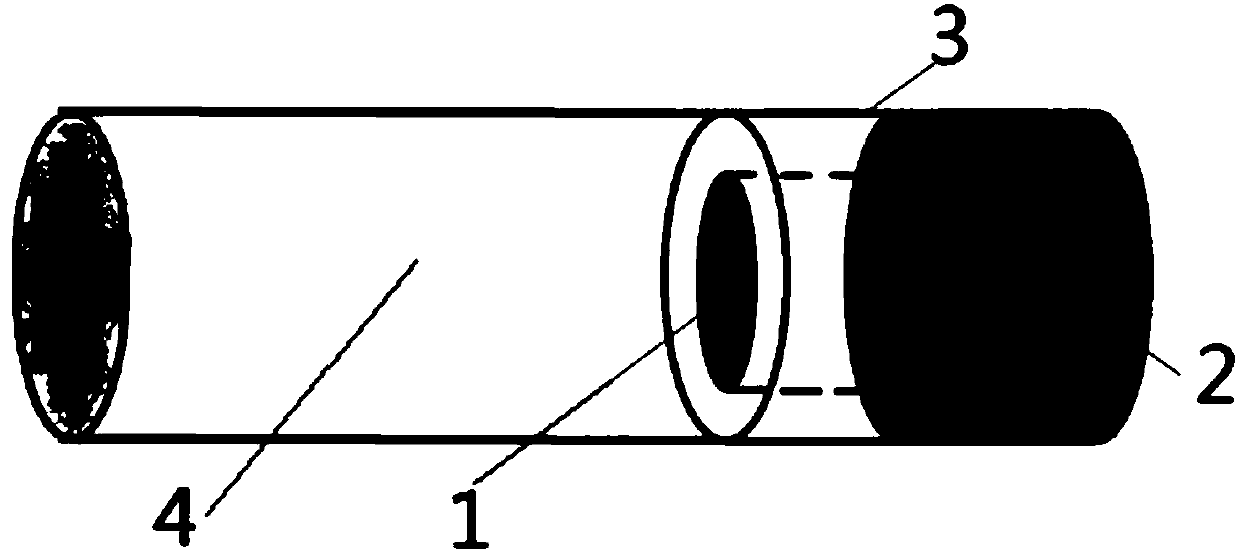

[0034] A cooling nozzle stick, comprising a cooling section, the cooling section includes a carrier with a cooling material applied on the surface, and the carrier is arranged in the cooling section to form a plurality of channels passing through the cooling section; the cooling material includes vegetable wax. The vegetable wax is extracted from tobacco.

[0035] The preparation method of the heat-not-burn cigarette of the present embodiment is as follows:

[0036] 1) After the wax on the tobacco surface is heated and extracted with an organic solvent, the solvent is evaporated and concentrated into an extract.

[0037] 2) After dispersing and dissolving an appropriate amount of extract with ethanol, spread it evenly on the cellulose paper, dry it in the air or dry it at low temperature to completely volatilize the ethanol.

[0038] 3) After cutting and creasing, the paper coated with tobacco wax is rolled into a cylindrical heat-not-burn cigarette cooling section, and then ...

Embodiment 2

[0041] A cooling nozzle stick, comprising a cooling section, the cooling section includes a carrier with a cooling material applied on the surface, and the carrier is arranged in the cooling section to form a plurality of passages passing through the cooling section; the cooling material is paraffin.

[0042] The preparation method of the heat-not-burn cigarette of the present embodiment is as follows:

[0043] 1) Melt paraffin with a melting point of 60°C.

[0044] 2) Spread the melted paraffin evenly on the cellulose paper, let it cool down to room temperature and wait for the paraffin to solidify.

[0045] 3) Roll the paraffin-coated paper into a cylindrical heat-not-burn cigarette cooling section after cutting and creasing, then connect and fix the tow with the wrapping paper to make a filter rod, and finally combine with the tobacco material section The connection is made into a heat-not-burn cigarette.

[0046] 4) The finished heat-not-burn cigarette can significantly ...

Embodiment 3

[0048] A cooling nozzle stick, including a cooling section, the cooling section includes a carrier with a cooling material applied on the surface, and the carrier is arranged in the cooling section to form a plurality of channels passing through the cooling section; the cooling material is paraffin, specifically For paraffin particles.

[0049] The preparation method of the heat-not-burn cigarette of the present embodiment is as follows:

[0050] 1) Make paraffin particles with a diameter of less than 1mm.

[0051] 2) Coat the melted hot melt adhesive on the cellulose paper first.

[0052] 3) Quickly bond the paraffin particles on the hot melt adhesive (spraying), and cool down to room temperature until the hot melt adhesive solidifies.

[0053] 4) After cutting, creasing, rolling and other processes, the paper glued with paraffin wax particles is made into a cylindrical heat-not-burn cigarette cooling section, and then connected and fixed with the tow through the wrapping p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com