Vacuum glass sealing method and product thereof

A vacuum glass and glass plate technology, applied in the field of vacuum glass sealing and its products, can solve the problems of increasing processing costs, endangering the environment and human health, reducing production efficiency, etc., and achieves high air tightness and good thermal shock resistance , the effect of firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing.

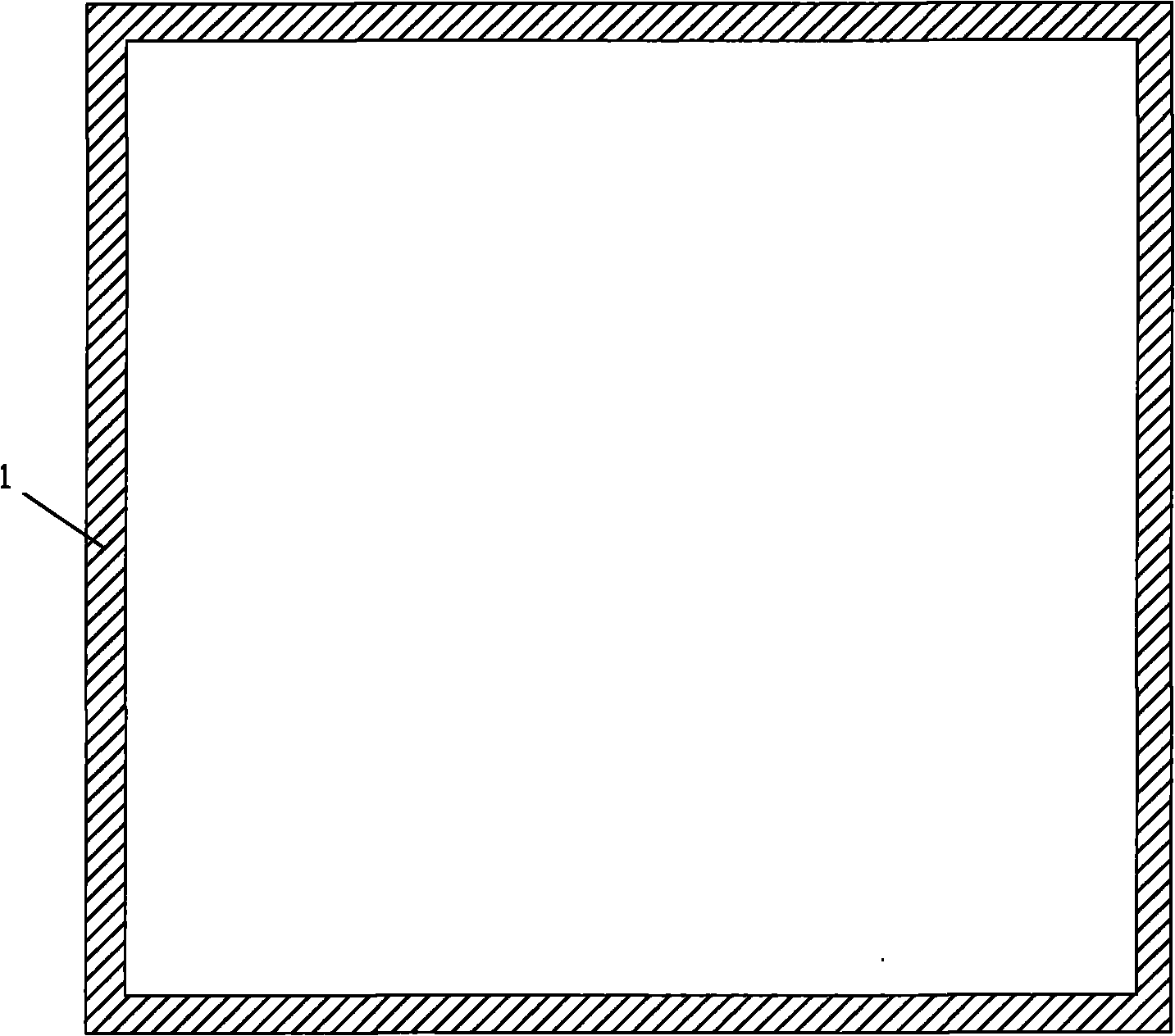

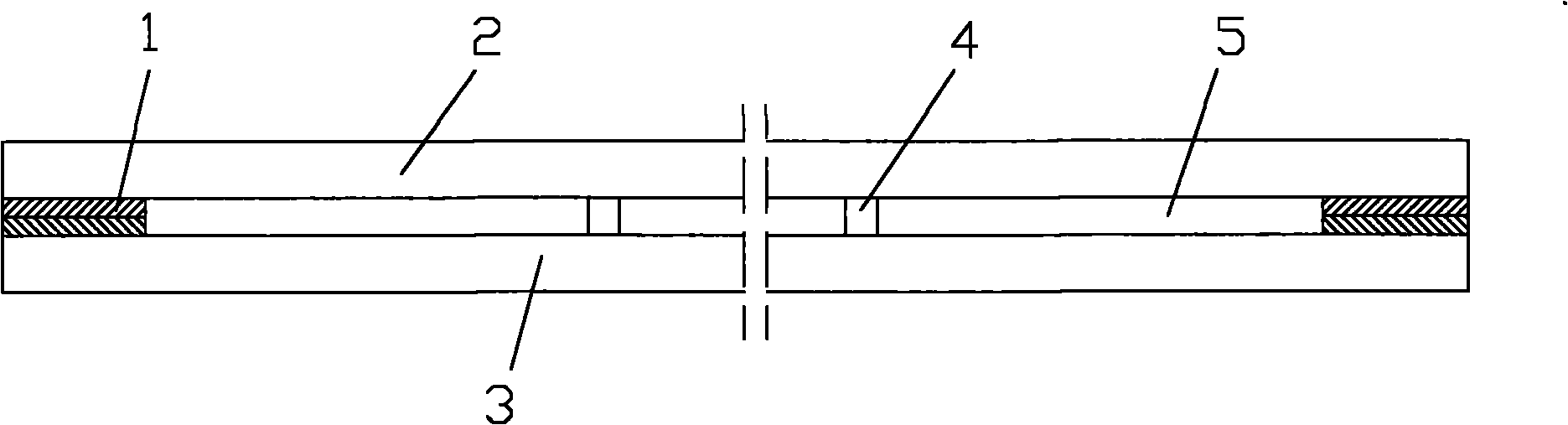

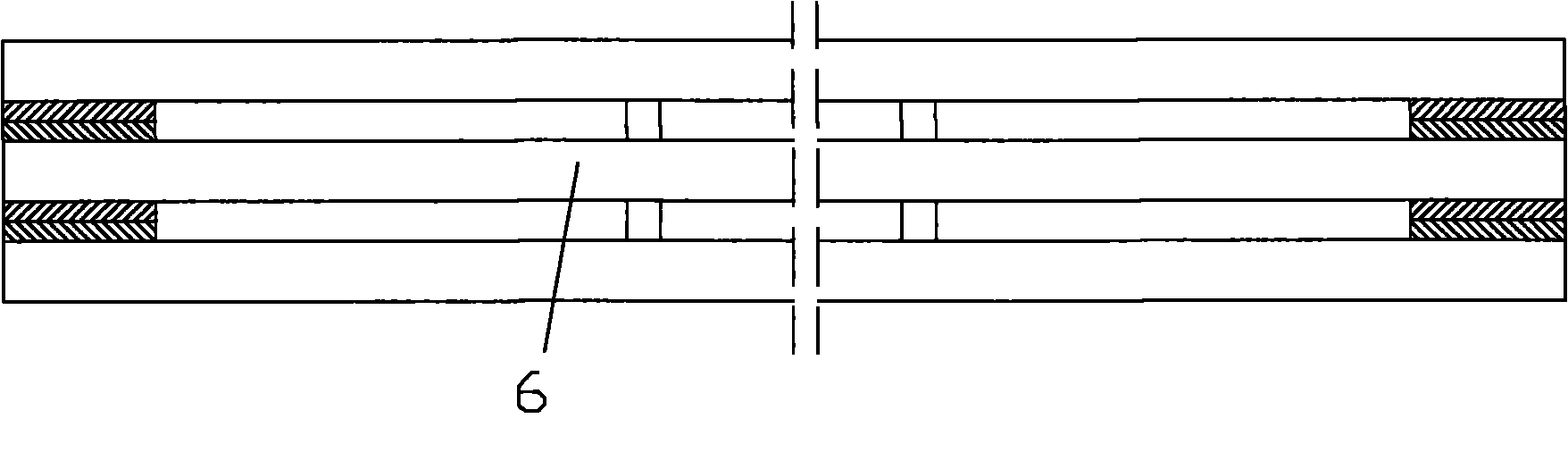

[0045] When making vacuum glass according to the sealing method of the present invention, first, prepare a metal layer solidified with the glass plate on the surface to be sealed at the edge of the glass plate, the metal layer is made of metal foil, and is welded on the glass by ultrasonic welding. On the board surface, the prepared metal layer 1 as figure 1 shown in; Then, press the two glass plates 2 and 3 to be sealed figure 2 The state shown is compounded, and metal brazing solder is arranged between the two corresponding metal layers 1 on the two glass plates 2 and 3; finally, the metal brazing process is used to directly connect the two corresponding metal layers on the two glass plates. The metal layers 1 are airtightly welded to each other to realize the airtight sealing of the edges of the two glass plates.

[0046] figure 2 Middle 4 is an intermediate support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com