Method for preparing wall material by using mercury ore tailings as raw materials

A technology for wall materials and tailings, which is applied in the field of preparing wall materials, can solve the problems of unsatisfactory promotion and use effect, complicated production process, consumption of land resources, etc., and achieves the effects of low production cost, simple production process and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1 of the present invention: carry out batching according to Table 1, obtain product of the present invention after molding, molding method can adopt existing mold natural molding or adopt conventional mold machine press molding method to carry out molding. Molded products have 3-day, 7-day, 28-day age strength. This product is formed, maintained and tested according to the requirements of the standard GB / T17671-1999 "Cement Mortar Strength Test Method (ISO Method)". The product strength test results are shown in Table 2.

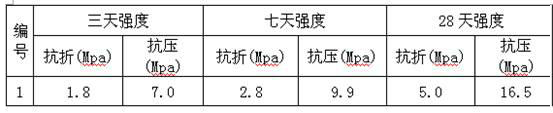

[0009] Table 1 Case formula (by weight)

[0010]

[0011] Table 2 Strength detection

[0012]

[0013] The product in this case satisfies the MU15 grade strength requirement of "Concrete Solid Brick" and meets the technical indicators of the present invention.

Embodiment 2

[0014] Embodiment 2 of the present invention: carry out batching according to table 3, obtain product of the present invention after molding, molding product has 3 days, 7 days, 28 days age strength. This product is formed, maintained and tested according to the requirements of the standard GB / T17671-1999 "Cement Mortar Strength Test Method (ISO Method)". The product strength test results are shown in Table 4.

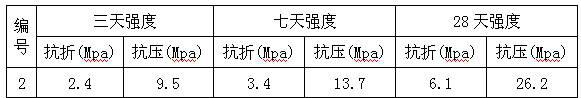

[0015] Table 3 case formula (by weight)

[0016]

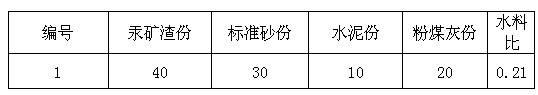

[0017] Table 4 Strength detection

[0018]

[0019] The product in this case meets the MU25 grade strength requirement of "Concrete Solid Brick", and meets the technical index of the present invention.

[0020] The above raw materials such as sand, fly ash and cement are purchased in the market as finished products. Wherein, cement can adopt the finished cement of labeling 425 or 325, all adopt 425 cement in the above-mentioned embodiment, if use 325 cement, only need to change the cement consumption and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com