Method for preparing long chain branched polylactic resin by combining two-step functional group reaction

A technology for long-chain branched polylactic acid and polylactic acid resin, applied in the field of preparing long-chain branched polylactic acid resin, can solve problems such as difficulty in adjusting the degree of product branching, product molecular weight and branching degree, and difficulty in ensuring product performance. , to achieve the effect of being conducive to large-scale continuous production, significant branching effect, and high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Synthesis of Long-chain Branched Polylactic Acid by Two-step Functional Group Reaction

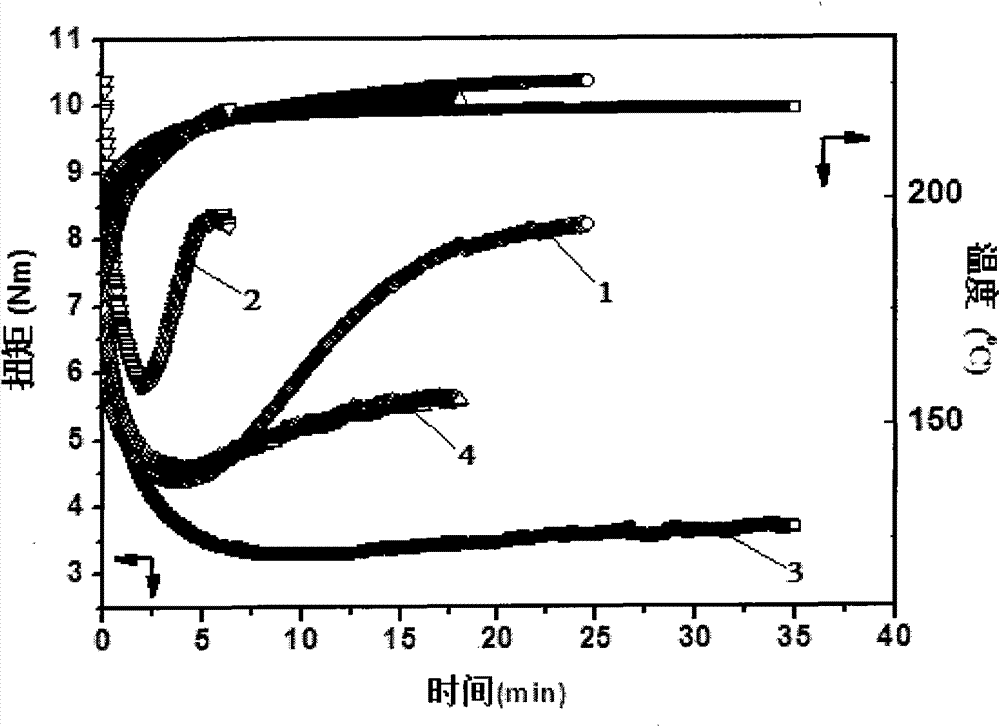

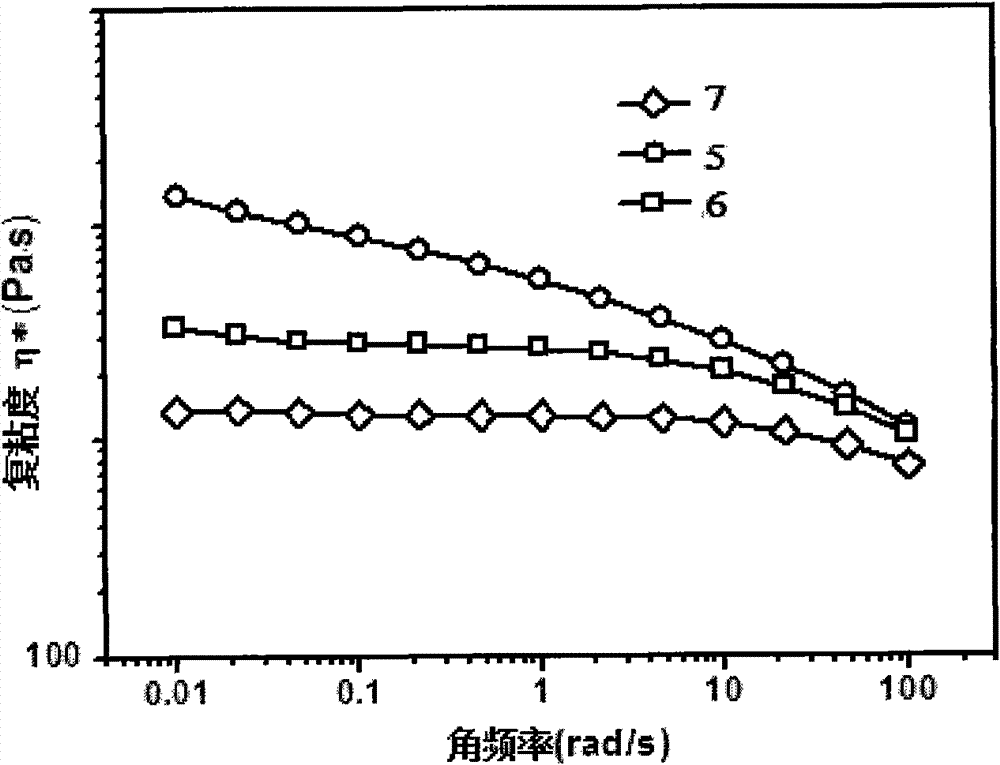

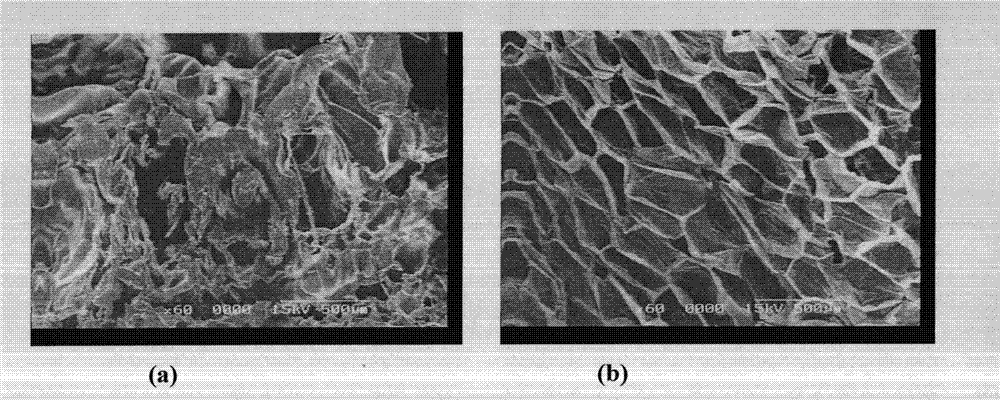

[0028] Add 100 parts by weight of polylactic acid resin to an internal mixer with a rotation speed of 20 rpm at 210°C, and add 0.15 parts of 1,3,5-trimethyl-2,4,6-tri(3, 5-di-tert-butyl-4-hydroxybenzyl)benzene, 0.30 parts of pyromellitic dianhydride, 0.61 parts of triglycidyl isocyanuric acid, mixed for 2 minutes; then the internal mixer was raised to 60rpm , Melt blending until the end of the reaction, that is, stop after about 25 minutes, to obtain long-chain branched polylactic acid. Table 1 shows the melt index (190° C., 2.16 kg load) of the obtained reaction product material measured according to the ASTM D1238 standard. The torque and temperature curves in the internal mixer are shown in figure 1 , at 180°C and the strain is 5% under the condition of viscosity change curve with frequency see figure 2 , the morphological image of the supercritical carbon dioxide foamed prod...

Embodiment 2

[0030] Synthesis of Long-chain Branched Polylactic Acid by Two-step Functional Group Reaction

[0031] Add 100 parts of polylactic acid resin to an internal mixer with a rotation speed of 20 rpm at 210°C, and then add 0.15 parts of 1,3,5-trimethyl-2,4,6-tris(3, 5-di-tert-butyl-4-hydroxybenzyl) benzene, 0.46 parts of pyromellitic dianhydride, 0.61 parts of triglycidyl isocyanuric acid, mixed for 2 minutes; then internal mixer was raised to 60rpm, blend until the end of the reaction, stop after about 25 minutes, and make long-chain branched polylactic acid. The melt index test results are shown in Table 1.

Embodiment 3

[0033] Synthesis of Long-chain Branched Polylactic Acid by Two-step Functional Group Reaction

[0034] Add 100 parts of linear polylactic acid industrial materials into a internal mixer with a rotation speed of 20 rpm at 210 ° C, and add 0.15 parts of 1,3,5-trimethyl-2,4,6-trimethyl-2,4,6-tri( 3,5-di-tert-butyl-4-hydroxybenzyl)benzene, 0.60 parts of pyromellitic dianhydride, 0.61 parts of triglycidyl isocyanuric acid, mixed for 2 minutes; then internal mixer Increase to 60rpm, blend until the end of the reaction, stop after about 25 minutes, and make long-chain branched polylactic acid. The melt index test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com