Control network connecting mode of drag-suction dredger power positioning control system

A trailing suction dredger, dynamic positioning technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problem of increased cost of construction and installation, increased length and strength of anchor chains, and weakened grip of anchor chains, etc. problems, to avoid communication inquiries, improve reliability, and avoid redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings.

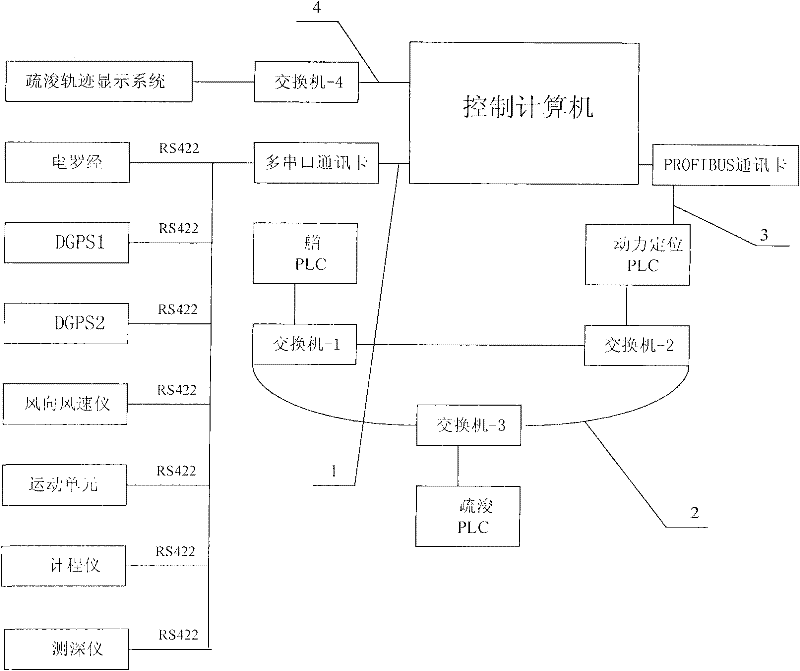

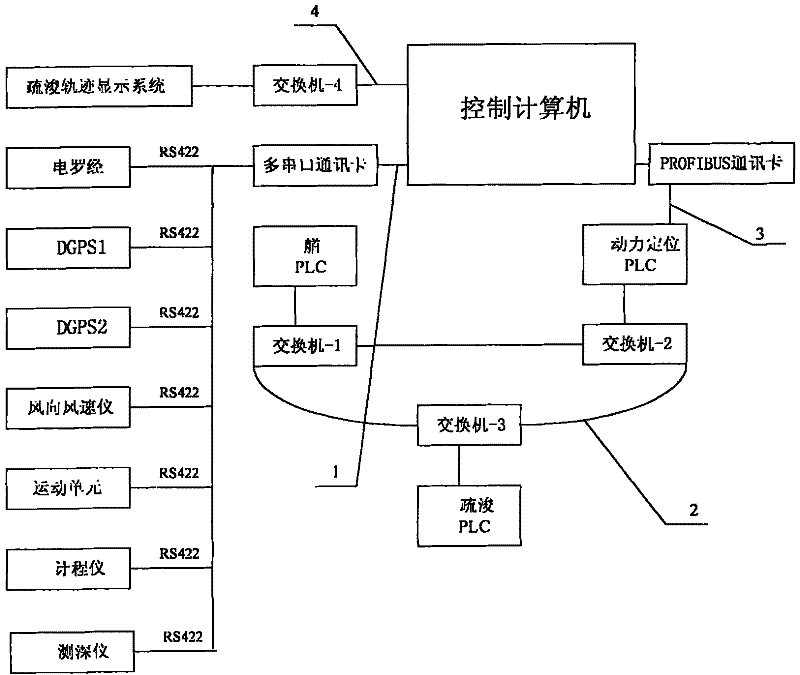

[0009] like figure 1 As shown, the present invention employs four types of networks.

[0010] Network (1) is responsible for collecting the information of gyrocompass, DGPS1, DGPS2, wind direction anemometer, motion unit, speed log and depth sounder. The network adopts industrial grade multi-serial port communication card, and the multi-serial port card is inserted into the PCI slot of the control computer , Each sensor is connected to each serial port of the multi-serial port card with shielded twisted pair, the communication interface is RS-422, and the communication protocol is NEMA 0183. Adopt MOXA CP118EL multi-serial port card, the multi-serial port card can connect 8 RS-232 / RS-422 / RS-485 signals, each serial port can support up to 921.6Kbps communication rate, 128-byte FIFO and on-chip Built-in H / W, S / W flow control function, the communication mode and commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com