High-temperature-resistant digital cable for automotive bus

A technology for digital cables and automobile buses, which is applied to cables, circuits, electrical components, etc. with double-stranded/quad-stranded, which can solve the problems of good heat resistance and wear resistance, and achieve good wear resistance. , The effect of good anti-interference performance and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

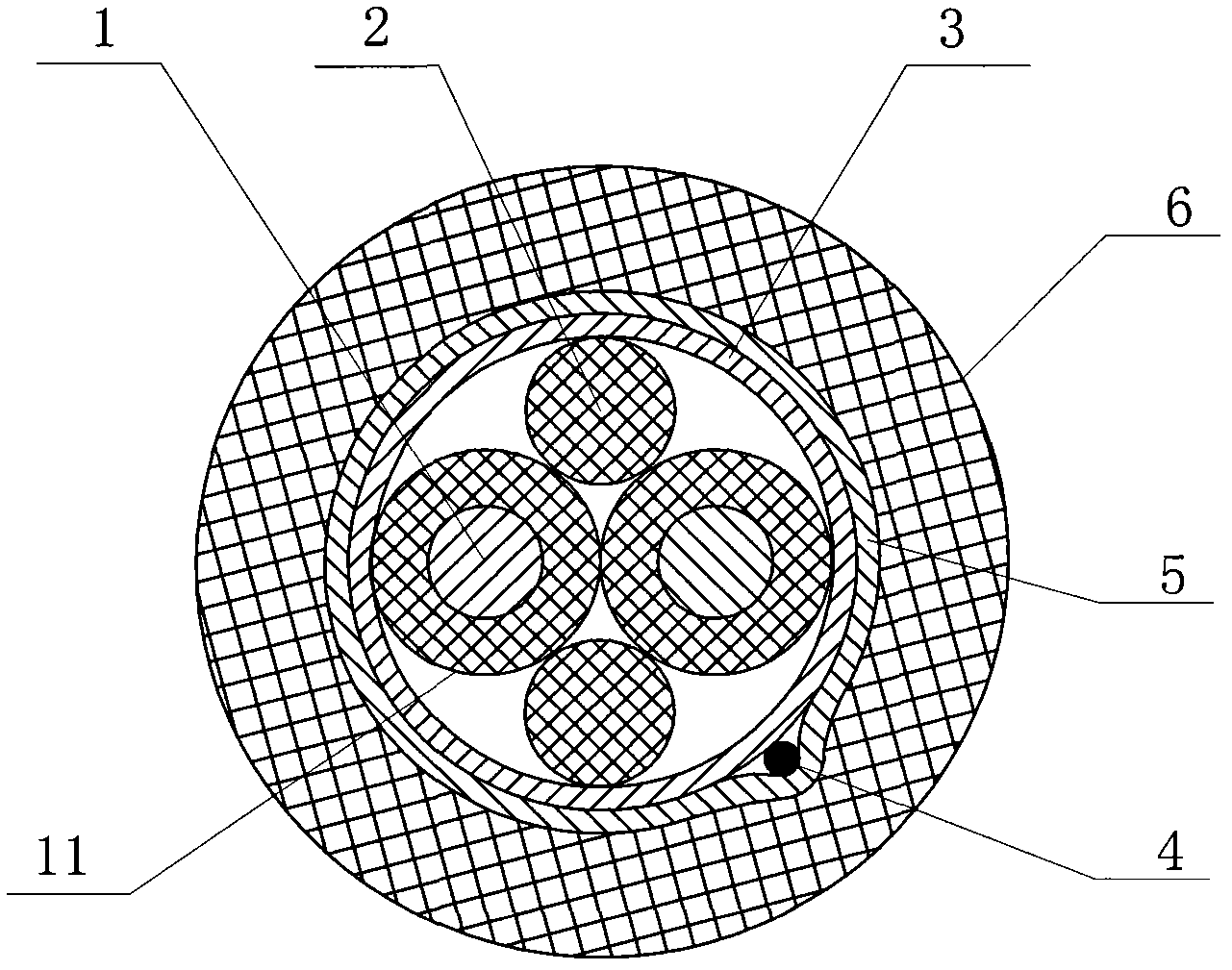

[0014] see figure 1 (accompanying drawing only shows the cross-section of the present invention, and the longitudinal appearance diagram of the present invention is omitted), and the high-temperature-resistant digital cable for automobile bus of the present invention has two digital signal transmission cores 1 arranged in parallel, and the digital signal transmission core 1 Filling cores 2 are arranged symmetrically on both sides. The digital signal transmission core and the filling core form a composite transmission core. A spiral-wrapped shielding layer 3 is arranged outside the composite transmission core. At least one interference signal lead-out core 4 parallel to the composite transmission core is set, a metal wire braided shielding layer 5 is arranged outside the spirally wrapped shielding layer, and a cable sheath 6 is arranged outside the metal wire braided shielding layer; The signal transmission wire core is composed of multi-strand copper wire bundles covered with ...

Embodiment 2

[0024] The high-temperature-resistant digital cable for automobile bus in this embodiment is an improvement on the basis of Embodiment 1. The technical content similar to that of Embodiment 1 will not be described here one by one. The technical content disclosed in Embodiment 1 is also It should be understood as the technical content disclosed in this embodiment.

[0025] In order to improve the high temperature resistance of the present invention, the maximum operating temperature of the insulating layer (normal operation) in the digital signal transmission core in the present embodiment is 150° C., and the material of the insulating layer is a cross-linked polyolefin material (150° C. XLPO; 150°C cross-linked polyolefin), fluoroplastics (polyfluoroethylene propylene FEP, commonly known as F46; ethylene-tetrafluoroethylene copolymer ETFE, commonly known as F40), elastomer insulating materials (TPE-E; thermoplastic polyester elastomer one of the materials). The maximum workin...

Embodiment 3

[0027] The high temperature resistant digital cable for the automobile bus in this embodiment is an improvement on the basis of the second embodiment.

[0028] In order to improve the high temperature resistance of the present invention, the maximum working temperature of the filled core in this embodiment is 150°C; the wire diameter of the filled core is 45%-65% of the digital signal transmission core wire diameter; the filled The core material is low-loss radiation cross-linked polyolefin material (150°C XLPO; 150°C cross-linked polyolefin), fluoroplastic (polyfluoroethylene propylene FEP, commonly known as F46; ethylene-tetrafluoroethylene copolymer ETFE, Commonly known as F40), elastomer insulation material (TPE-E; thermoplastic polyester elastomer material).

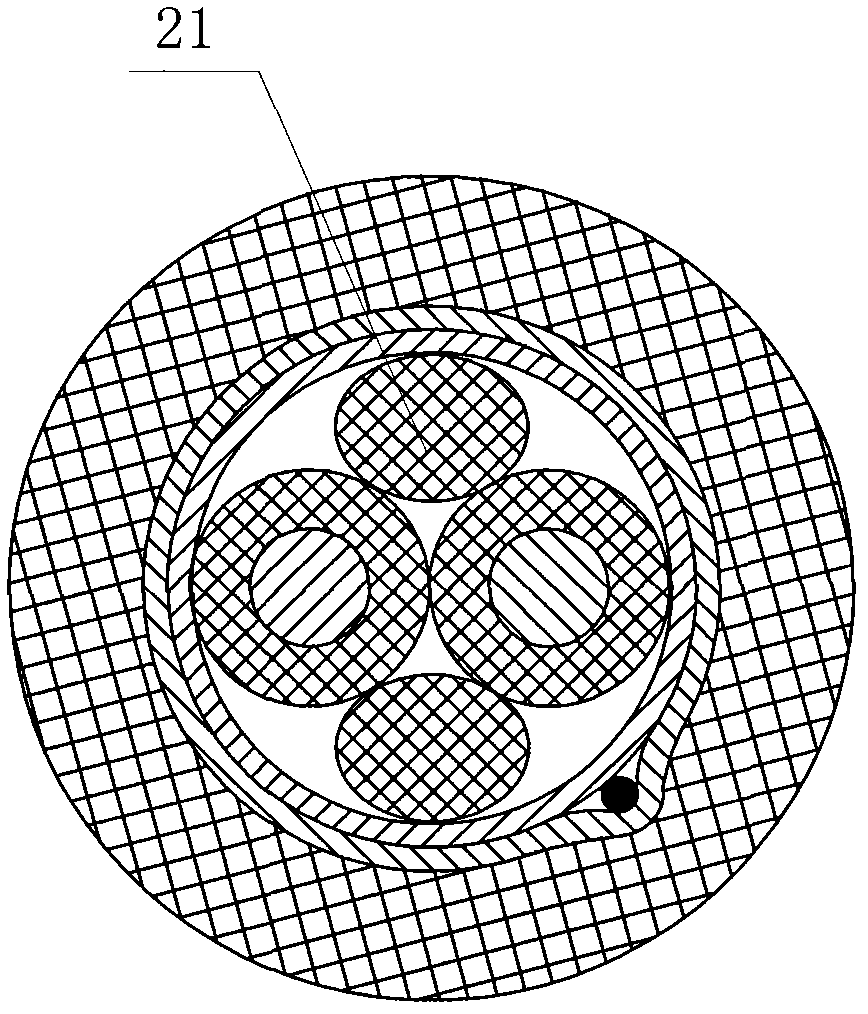

[0029] see figure 2 , in this embodiment, in order to improve the transmission performance and overall performance of the cable, the filled core 21 is designed to be an irregular oval shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com