F<-> and Zn<2+> co-doped NASICON type solid lithium ion electrolyte

A solid electrolyte, lithium ion technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as the conductivity of non-thin film lithium ion batteries to electrolytes that cannot be well met, reduce transmission bottlenecks, and improve conductivity. , to avoid the effect of structural distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

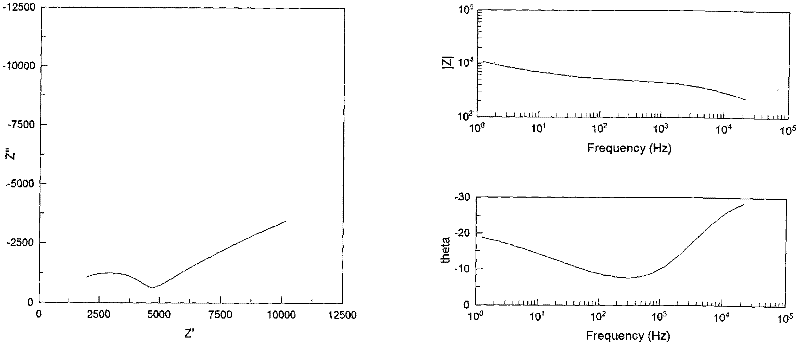

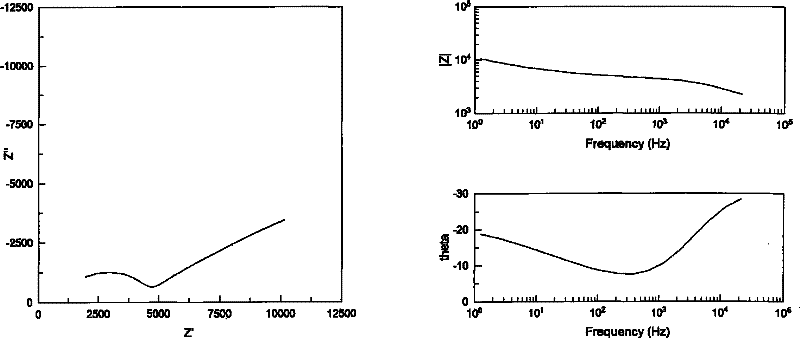

Image

Examples

Embodiment 1

[0010] Embodiment 1: ZnO: LiF: TiO 2 : NH 4 h 2 PO 4 : Li 2 CO 3Be 0.1: 0.1: 1.9: 3.0: 0.5 (molar ratio) ratio homogeneous mixing, add 3% 95% ethanol, in ball mill with the speed ball milling of 100 rev / mins 15 hours, after ball milling finishes, in 60 ℃ of vacuum ovens ( Dry in a vacuum degree of 20 Pa) for 3 hours, take it out and re-grind in an agate mortar for 30 minutes, and the ground powder is heated at a rate of 6°C / min to 700°C for 6 hours to make a solid electrolyte powder. The powder is mixed with 2wt% binder (PVC) and kept under a pressure of 250MPa for 2 minutes under a press to form a thin sheet, which is heated to 800°C at a rate of 10°C / min and kept for 10 hours under a nitrogen atmosphere to make lithium Ionic solid electrolyte sheets.

Embodiment 2

[0011] Example 2: ZnO: LiF: GeO 2 : NH 4 h 2 PO 4 : Li 2 CO 3 Be 0.3: 0.1: 1.7: 3.0: 0.7 (molar ratio) ratio homogeneous mixing, add 9% 95% ethanol, in ball mill with the speed ball milling of 450 rev / mins 45 hours, after ball milling finishes, in 80 ℃ of vacuum ovens ( Vacuum (95Pa) was dried for 9 hours, taken out and re-grinded in an agate mortar for 30 minutes, and the ground powder was heated to 950°C at a rate of 25°C / min and kept for 15 hours to make a solid electrolyte powder. The powder is mixed with 5wt% binder (PVC) and kept under a pressure of 450MPa for 6 minutes under a press to form a thin sheet, which is heated to 1000°C at a rate of 25°C / min and kept for 10 hours under a nitrogen atmosphere to make lithium Ionic solid electrolyte sheets.

Embodiment 3

[0012] Embodiment 3: ZnO: LiF: ZrO 2 : NH 4 h 2 PO 4 : Li 2 CO 3 Be 0.5: 0.2: 1.5: 3.0: 0.8 (molar ratio) ratio homogeneous mixing, add 5% 95% ethanol, ball mill with the rotating speed of 300 rev / mins in ball mill for 30 hours, after ball mill finishes, in 75 ℃ vacuum oven ( Dry in vacuum (50 Pa) for 6 hours, take it out and re-grind in an agate mortar for 20 minutes, and the ground powder is heated to 850°C at a rate of 10°C / min and kept for 12 hours to make a solid electrolyte powder. The powder is mixed with 2.6wt% binder (PVA) and kept under a pressure of 400 MPa under a press for 4 minutes to form a thin sheet. The thin sheet is heated to 900°C at a rate of 15°C / min and kept for 7 hours under a nitrogen atmosphere. Lithium ion solid electrolyte sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com