Permanent-magnet surface-mounted motor rotor with fixed plates

A technology of motor rotor and stator, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of high rotor temperature, permanent magnet, large loss of fixed plate, low motor efficiency, etc., and achieve reduction Small rotor heats up, improves motor efficiency, and reduces loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

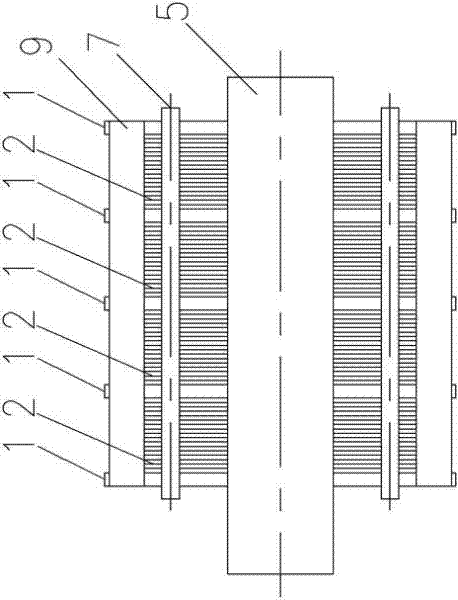

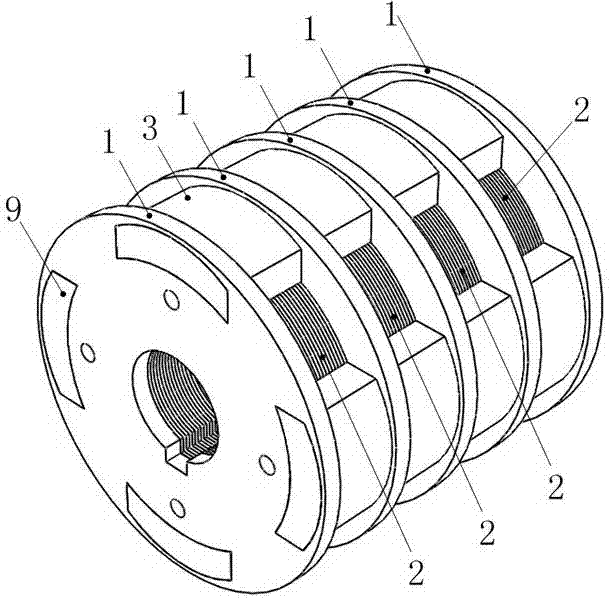

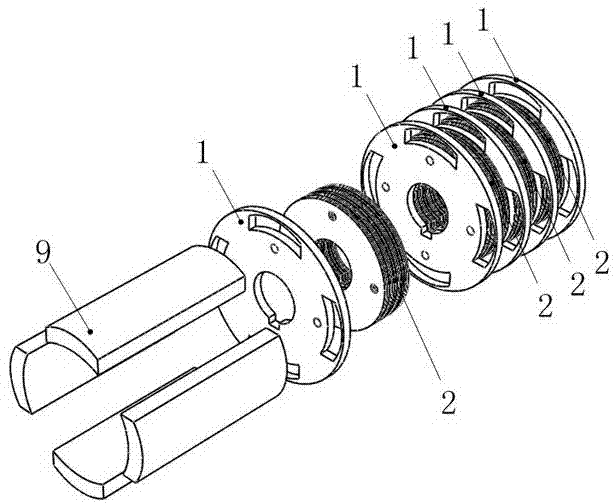

[0021] Embodiment 1: The permanent magnet surface-mounted motor rotor of this example has a fixed piece, such as figure 1 , figure 2 , image 3 , there are some fixed plates 1, and the fixed plates are made of iron. An iron core sheet 2 is arranged between two adjacent fixed sheets, and the iron core sheet is made of silicon steel laminations with a certain thickness. Such as Figure 4 , The middle part of the fixed piece has a fixed piece axis hole 3. Such as Figure 5 , the middle part of the iron core sheet has an iron core sheet shaft hole 4 that is consistent with the shape of the shaft hole of the fixed sheet, and a shaft body 5 is connected in the shaft hole to fix all the fixed sheets and the iron core sheets together. The fixed sheet shaft hole, the iron core sheet shaft Fastening holes 6 are evenly distributed on the fixed piece and the iron core piece around the hole, and a fixed rod 7 is connected in the fastening hole. The diameter of the fixed piece is larg...

Embodiment 2

[0023] Embodiment 2: The permanent magnet surface-mounted motor rotor of this example has a fixed piece, such as Figure 6 , Figure 7 , there are some fixed plates 1, and the fixed plates are made of iron. An iron core sheet 2 is arranged between two adjacent fixed sheets, and the iron core sheet is made of silicon steel laminations with a certain thickness. Such as Figure 4 , The middle part of the fixed piece has a fixed piece axis hole 3. Such as Figure 5 , the middle part of the iron core sheet has an iron core sheet shaft hole 4 that is consistent with the shape of the shaft hole of the fixed sheet, and a shaft body 5 is connected in the shaft hole to fix all the fixed sheets and the iron core sheets together. The fixed sheet shaft hole, the iron core sheet shaft Fastening holes 6 are also evenly distributed on the fixed piece and the iron core sheet on the periphery of the hole, and a fixed rod 7 is pierced in the fastening hole. The diameter of the fixed piece is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com