Hydroprocessing method for coking kerosene distillates

A technology for hydrotreating and kerosene, which is applied in hydrotreating process, treating hydrocarbon oil, petroleum industry, etc., can solve the problem of difficulty in treating inferior naphthenic coking distillate oil, and achieve the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

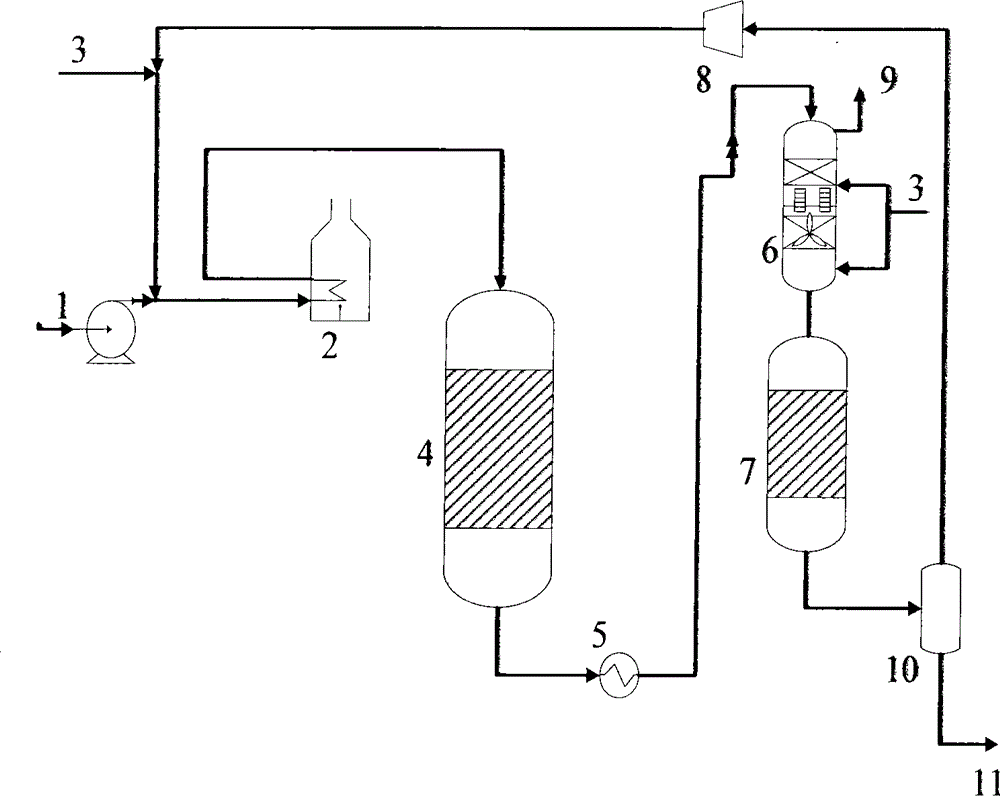

Method used

Image

Examples

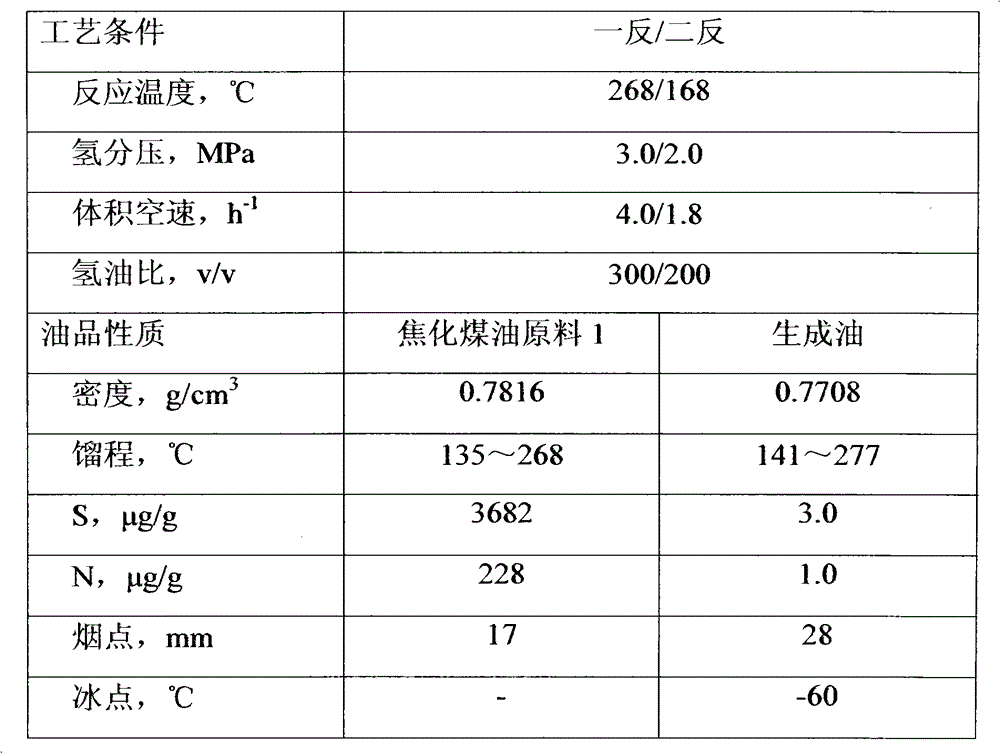

Embodiment 1

[0030] Coked kerosene raw material 1 enters the first hydrogenation reactor, and the reaction conditions are: hydrogen partial pressure 3.0MPa, volume space velocity 4.0h -1 , The reaction temperature is 268°C, and the volume ratio of hydrogen to oil is 300:1; the effluent enters the second hydrogenation reactor after being passed through the gas stripping hydrogen dissolver, and the reaction conditions are: hydrogen partial pressure 2.0MPa, volume space velocity 1.8h -1 , The reaction temperature is 168° C., and the volume ratio of hydrogen to oil is 200:1. The raw material oil properties and product properties are listed in Table 2.

[0031] It can be seen from Table 2 that the smoke point of kerosene products can meet the index requirements of greater than 25mm by using this process technology, and other properties can directly meet the quality requirements of the national standard 3# jet fuel.

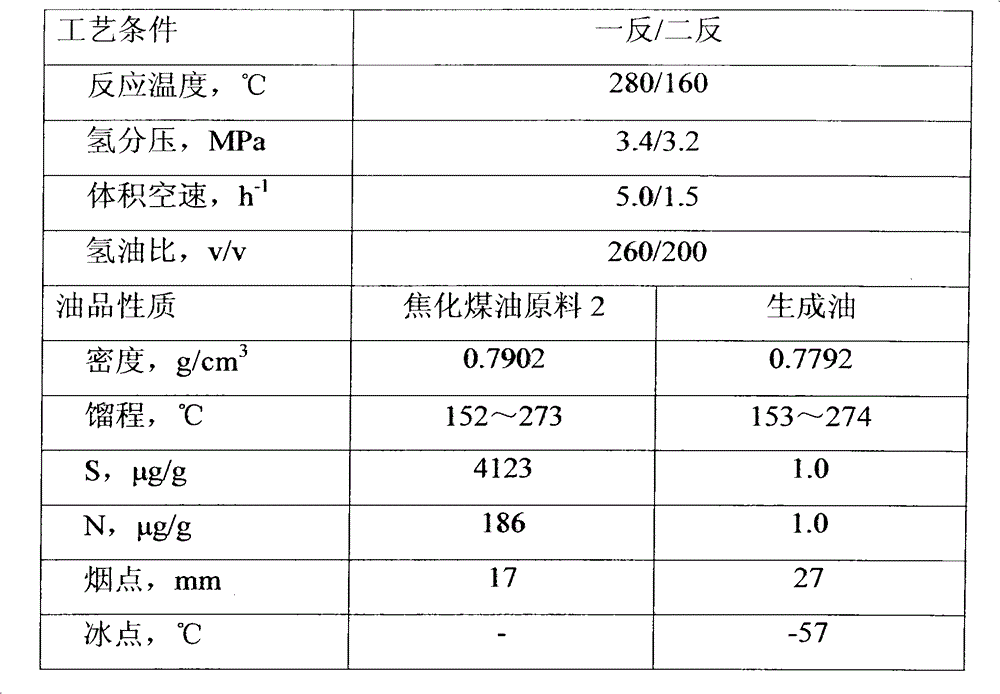

Embodiment 2

[0033] Coking kerosene raw material 2 enters the first hydrogenation reactor, the reaction conditions are: hydrogen partial pressure 3.4MPa, volume space velocity 5.0h -1 , The reaction temperature is 280°C, and the volume ratio of hydrogen to oil is 260:1; the effluent enters the second hydrogenation reactor after being passed through the hydrogen stripping device, and the reaction conditions are: hydrogen partial pressure 1.8MPa, volume space velocity 1.5h -1 , The reaction temperature is 160°C, and the volume ratio of hydrogen to oil is 200:1. The raw material oil properties and product properties are listed in Table 3.

[0034] It can be seen from Table 3 that the smoke point of kerosene products can meet the index requirements of greater than 25mm by using this process technology, and other properties can directly meet the quality requirements of the national standard 3# jet fuel.

Embodiment 3

[0036] Coking kerosene raw material 3 enters the first hydrogenation reactor, the reaction conditions are: hydrogen partial pressure 2.6MPa, volume space velocity 3.2h -1 , The reaction temperature is 260°C, and the volume ratio of hydrogen to oil is 350:1; the effluent enters the second hydrogenation reactor after being passed through the hydrogen stripping device, and the reaction conditions are: hydrogen partial pressure 2.4MPa, volumetric space velocity 2.0h -1 , The reaction temperature is 180°C, and the volume ratio of hydrogen to oil is 300:1. The raw material oil properties and product properties are listed in Table 4.

[0037] It can be seen from Table 4 that the smoke point of kerosene products can meet the index requirements of greater than 25mm by using this process technology, and other properties can directly meet the quality requirements of the national standard 3# jet fuel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com