Light-emitting diode structure, and manufacturing method thereof

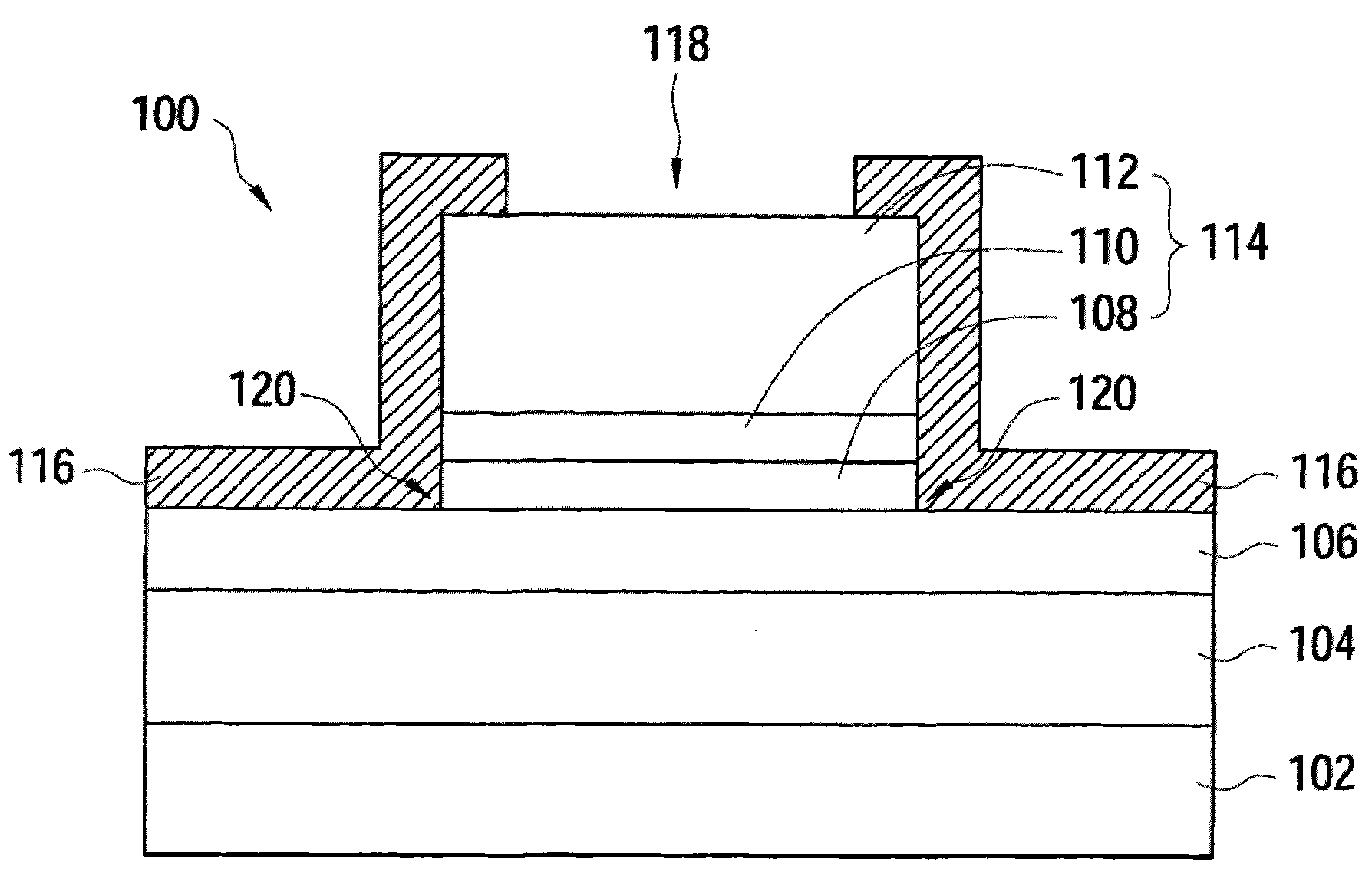

A technology of light emitting diodes and manufacturing methods, applied to electrical components, circuits, semiconductor devices, etc., capable of solving problems affecting the stability of the light emitting diode structure 100, decreased adhesion of electrodes 114, abnormal electrical properties of the light emitting diode structure 100, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

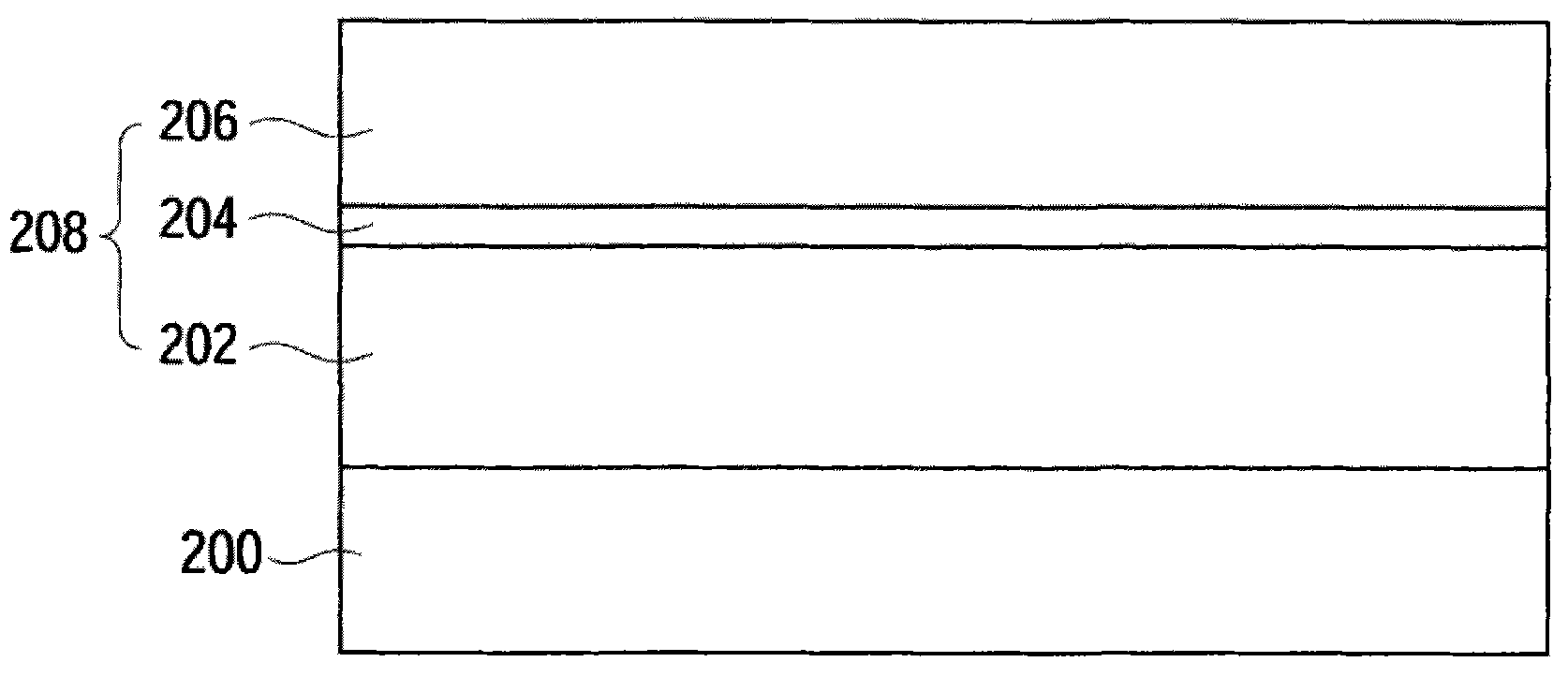

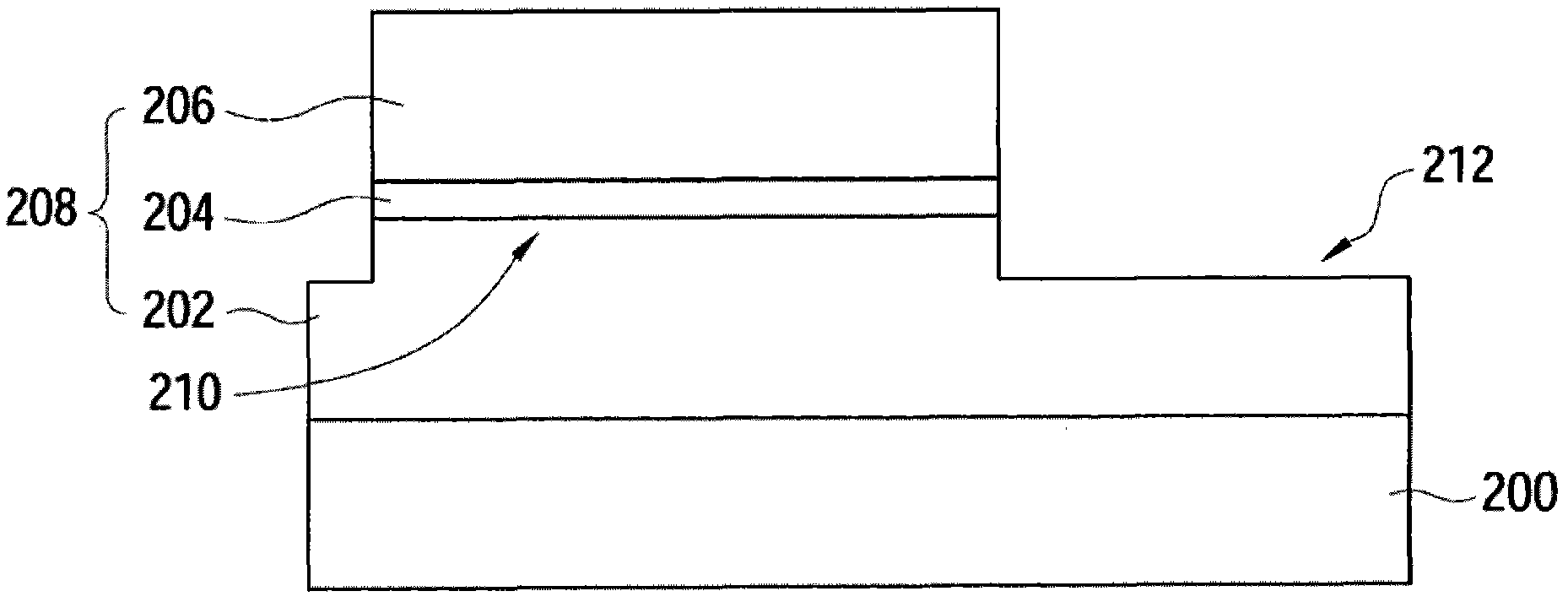

[0051] Please refer to Figure 2A to Figure 2E , which is a cross-sectional view illustrating a manufacturing process of a light emitting diode structure according to an embodiment of the present invention. In this embodiment, when fabricating the light emitting diode structure, the substrate 200 may be firstly provided for the growth of the epitaxial layer thereon. The material of the substrate 200 can be, for example, sapphire, silicon carbide (SiC), gallium arsenide (GaAs) or gallium nitride (GaN). Next, an epitaxial structure 208 is grown on the surface of the substrate 200 using, for example, an epitaxy method. In one embodiment, as Figure 2A As shown, the first electrical type semiconductor layer 202 , the light emitting layer 204 and the second electrical type semiconductor layer 206 can be sequentially grown on the substrate 200 by metal organic chemical vapor deposition (MOCVD) to form the epitaxial structure 208 . Wherein, the first electrical type is, for exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com