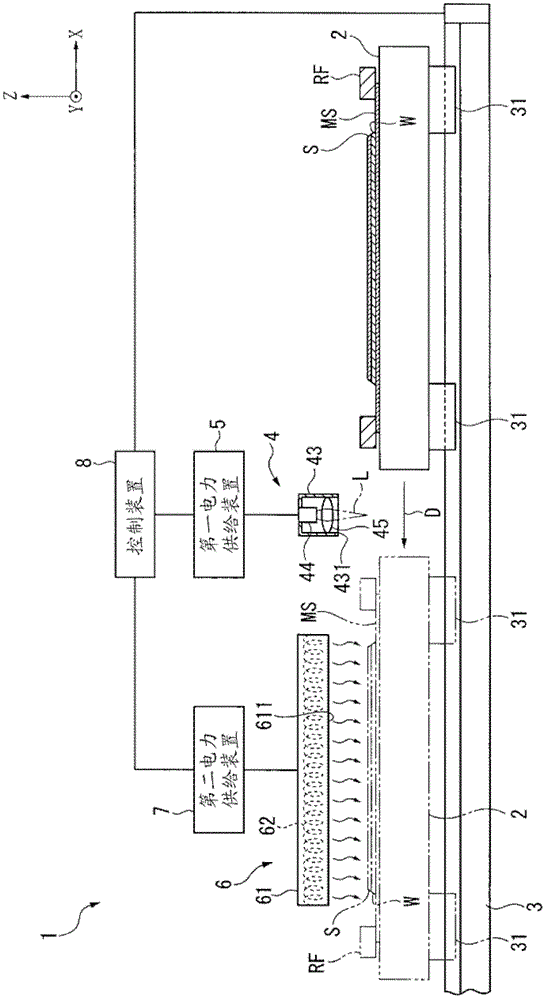

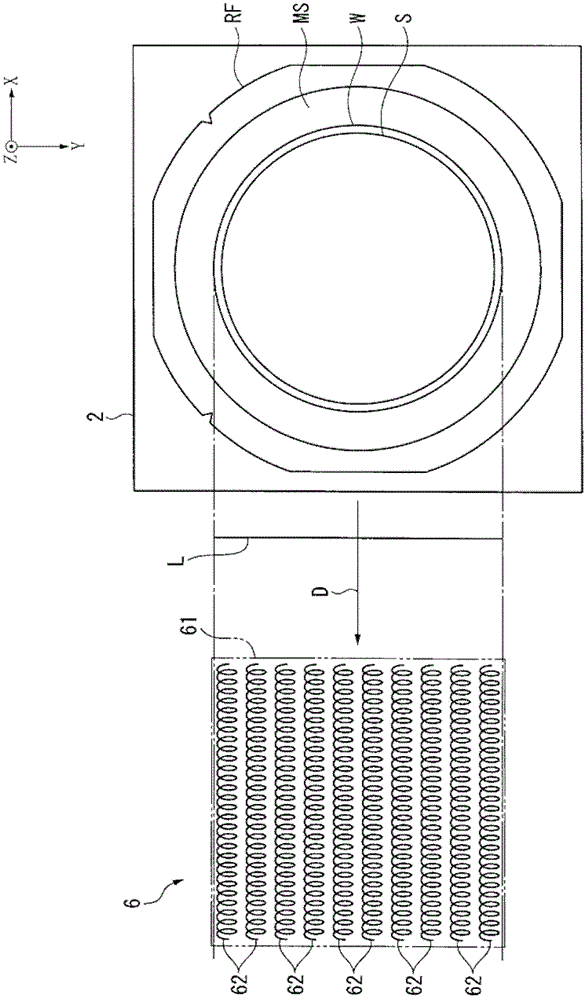

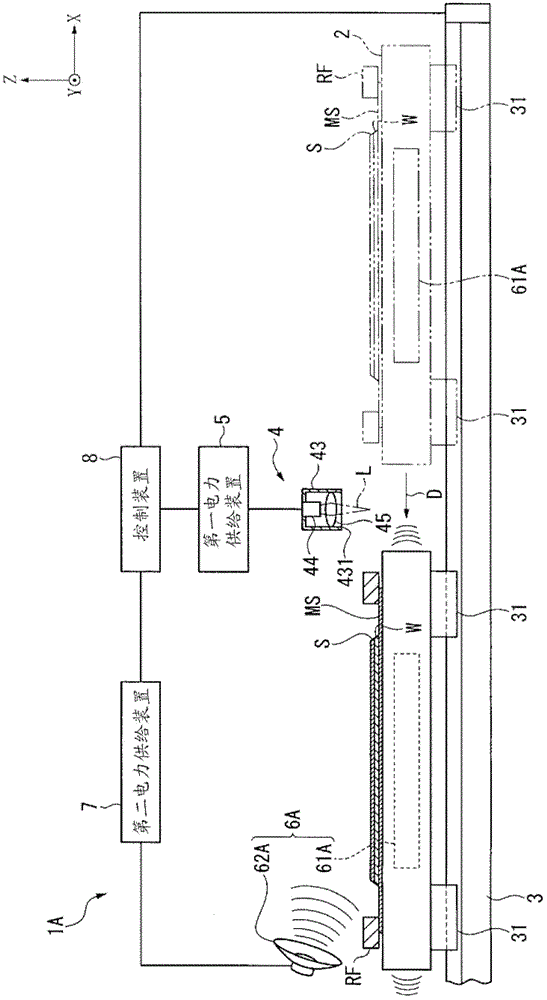

Energy application device and energy application method

A technology of energy supply and energy, applied in bonding methods, chemical instruments and methods, chemical/physical/physical-chemical processes of applying energy, etc., which can solve problems such as easy peeling, non-hardening and damage of the adhesive layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In Example 1, the adhesive force when the adhesive material layer of the dicing tape was photocured using light of a single wavelength of 365 nm and heat was evaluated.

[0065] First, the dicing tape attached to the stainless steel plate was irradiated with 365 nm single-wavelength light through the same dicing tape sticking step and single-wavelength light irradiation step as in Comparative Example 2.

[0066] Afterwards, utilize the spot heater (model: SH01 / 1100-035K) that Co., Ltd. Bamboo Net Manufacturing Institute (Co., Ltd. Bamboo Net Manufacturing Co., Ltd.) makes to heat the cutting tape (heating step), and use the same method as Comparative Examples 1 and 2. Evaluation Step The adhesive force was evaluated. In addition, samples having different light quantities in the single-wavelength light irradiation step were prepared and evaluated in the same manner.

[0067] Such as Figure 4 As shown, the adhesive force changed between 180 to 260mN / 25mm, and became a ...

Embodiment 2

[0069] In Example 2, the adhesive force when the adhesive material layer of the dicing tape was photocured using light of a single wavelength of 365 nm and high frequency was evaluated.

[0070] First, the dicing tape pasted on the stainless steel plate was irradiated with 365 nm single-wavelength light through the same dicing tape sticking step and single-wavelength light irradiation step as in Comparative Example 2 and Example 1.

[0071] Afterwards, a high-frequency generating device (model: DIHS105-MT1) manufactured by HIDEC Co., Ltd. (Hidec Co., Ltd.) was used to provide high-frequency to the stainless steel plate with the dicing tape attached, and by comparing with Comparative Example 1, Comparative Example 2, and Example 1 Adhesion was evaluated in the same evaluation procedure. In addition, samples having different light quantities in the single-wavelength light irradiation step were prepared and evaluated in the same manner.

[0072] Such as Figure 4 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com