Method for producing silica-zirconia composite particles each coated with silica layer

A technology of silicon dioxide and manufacturing method, applied in the directions of silicon dioxide, zirconia, silicon oxide, etc., can solve the problem of difficulty in obtaining monodispersity, and achieve the effect of excellent X-ray contrast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

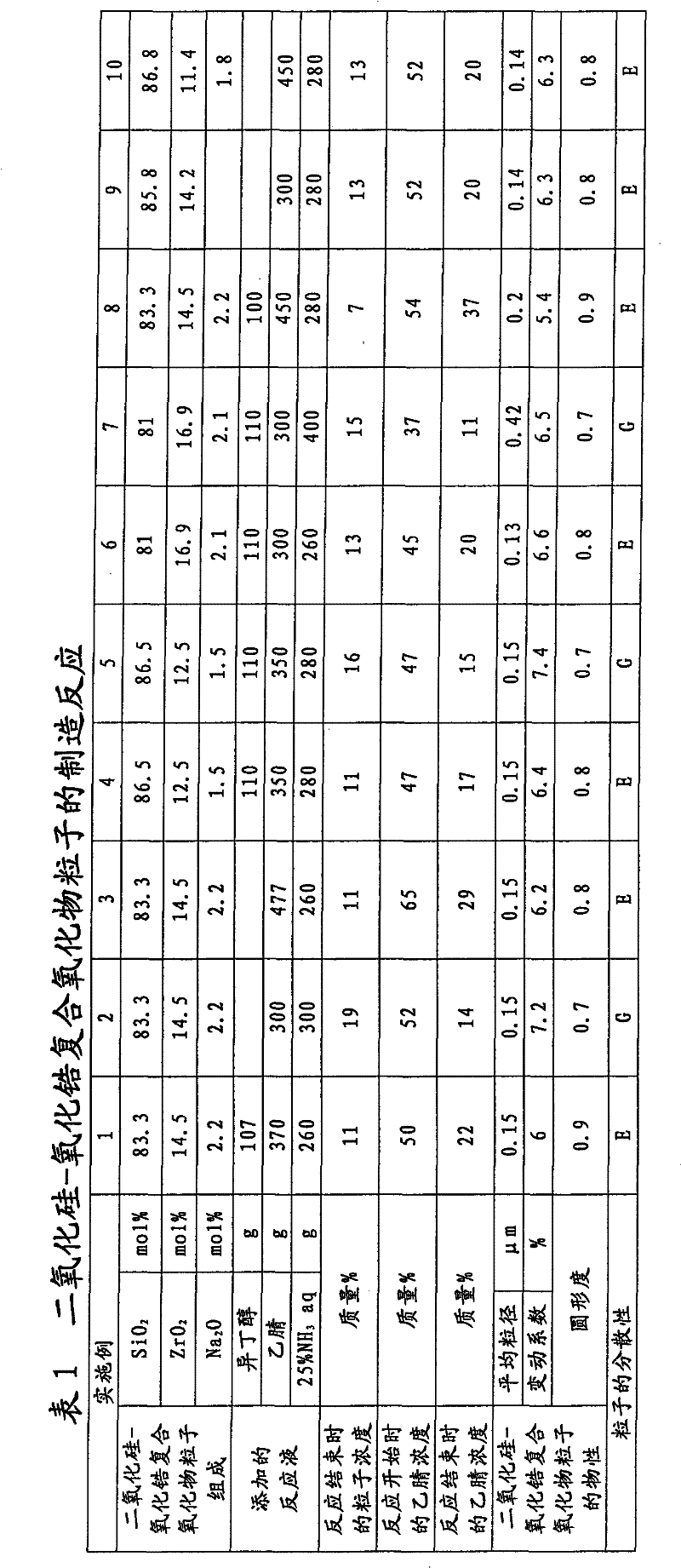

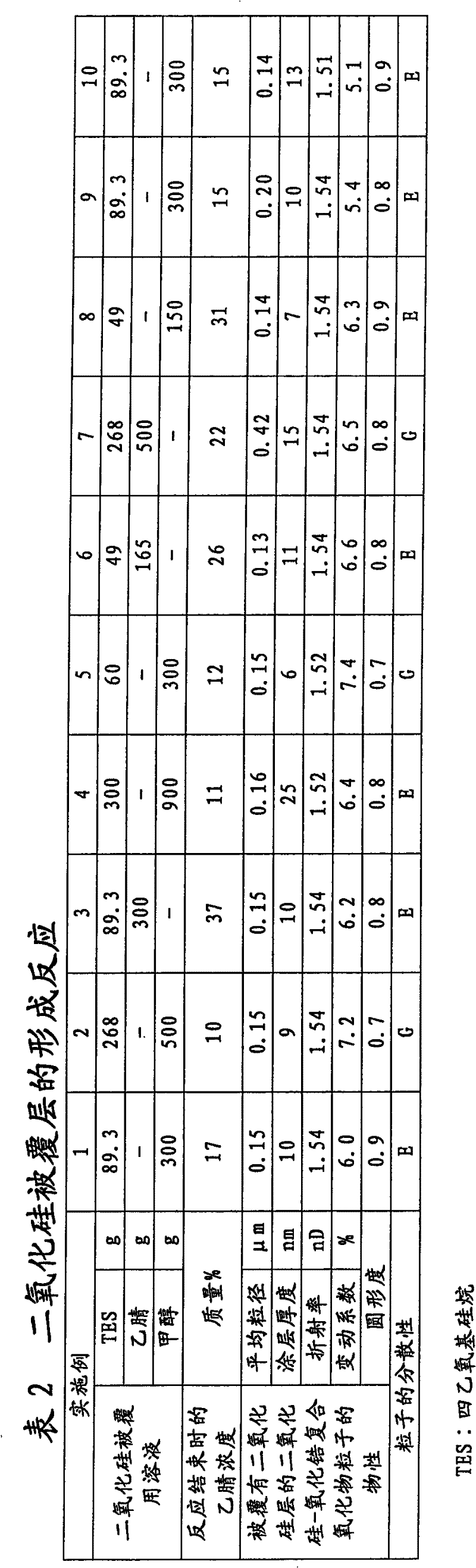

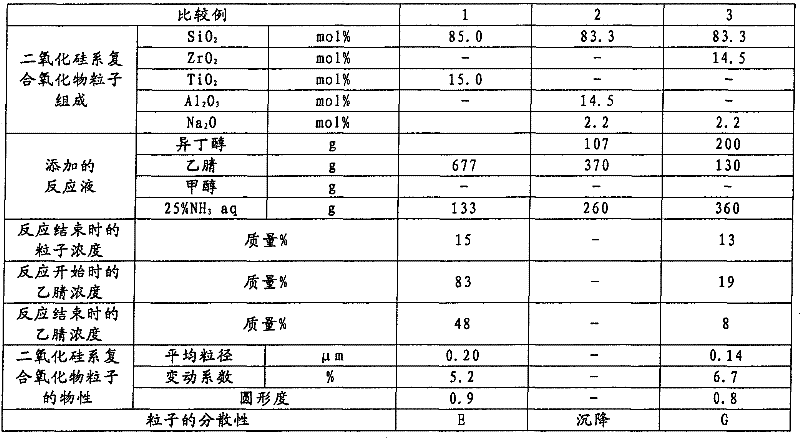

Examples

Embodiment 1

[0127] (Preparation of alkoxide solution for composite oxide particles)

[0128] 356 g of tetraethoxysilane (Colcoat Co., Ltd.) and 427 g of isobutanol were added to a 2-liter Erlenmeyer flask and stirred. 8.9 g of 0.06% by mass of dilute sulfuric acid was added thereto, followed by stirring for 17 hours to perform partial hydrolysis of tetraethoxysilane. Then, 114 g of tetrabutyl zirconate (Honking Chemical Industry Co., Ltd., trade name: HZ-NB) and 17.3 g of 28% sodium methoxide (Wako Pure Chemical Industries, Ltd.) were added to the obtained reaction liquid to obtain a colorless and transparent compound Alkoxide solution for oxide particle production.

[0129] (Manufacture of silica-zirconia composite oxide particles)

[0130] 370 g of acetonitrile, 107 g of isobutanol, and 260 g of aqueous ammonia (25% by mass) were charged into a jacketed glass reactor having a stirring blade and an inner volume of 3 liters. The temperature of the circulating water in the jacket was se...

Embodiment 2

[0138] (Preparation of alkoxide solution for composite oxide particle production)

[0139] 786 g of tetraethoxysilane (Colcoat Co., Ltd.) and 444 g of isobutanol were added to a 3-liter Erlenmeyer flask, and stirred. Furthermore, 22.2 g of 0.06 mass % dilute sulfuric acid was added, and the partial hydrolysis of tetraethoxysilane was performed for 17 hours. Then, 228 g of tetrabutyl zirconate (Honking Chemical Industry Co., Ltd., trade name: HZ-NB) and 34.6 g of 28% sodium methoxide (Wako Pure Chemical Industries, Ltd.) were added to the obtained reaction solution to obtain a colorless and transparent compound Alkoxide solution for oxide particle production.

[0140] (Manufacture of silica-zirconia composite oxide particles)

[0141] 300 g of acetonitrile and 280 g of aqueous ammonia (25% by mass) were respectively charged into a jacketed glass reactor having a stirring blade and an internal volume of 3 liters. The temperature of the circulating water in the jacket was set ...

Embodiment 3

[0149] (Preparation of alkoxide solution for composite oxide particles)

[0150] The same alkoxide solution for producing complex oxide particles as that used in Example 1 was used.

[0151] (Manufacture of silica-zirconia composite oxide particles)

[0152] 477 g of acetonitrile and 260 g of aqueous ammonia (25% by mass) were charged into a jacketed glass reactor having a stirring blade and an internal volume of 3 liters. The temperature of the circulating water in the jacket was set at 40°C. The stirring blade was rotated at 180 rpm to stir the inside of the reactor. 923.2 g (total amount) of the aforementioned alkoxide solution for producing complex oxide particles prepared in advance was supplied into the reaction solvent over 7 hours, and stirred for 20 minutes after the supply.

[0153] Through the above reaction, a silica-zirconia composite oxide particle dispersion liquid was obtained. The particle concentration was 11% by mass. The result of evaluating the disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com