980 optical fiber for small-diameter coupler

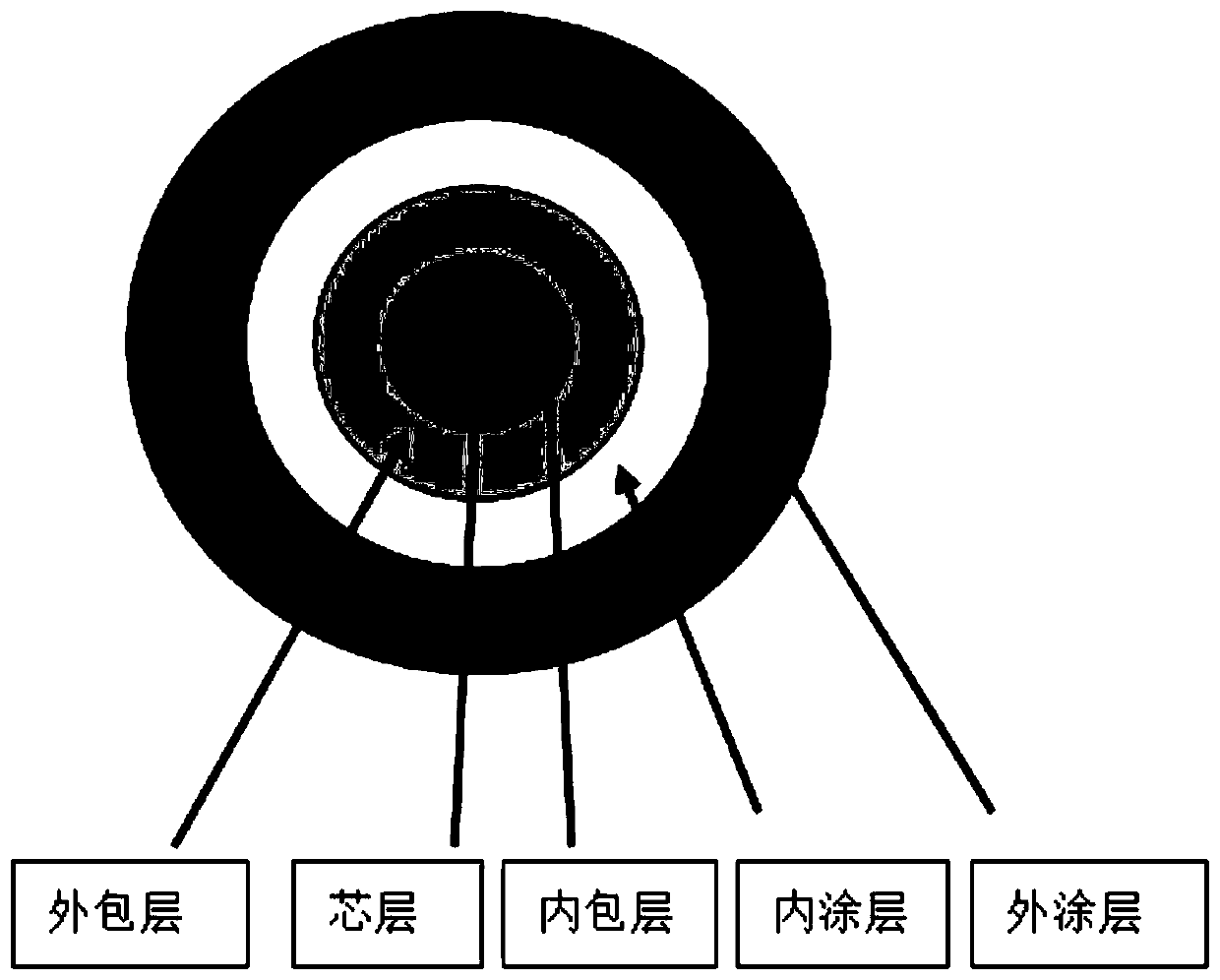

A coupler and optical fiber technology, which is applied to clad optical fibers, multi-layer core/clad optical fibers, light guides, etc. to reduce attenuation, loss, and splice loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

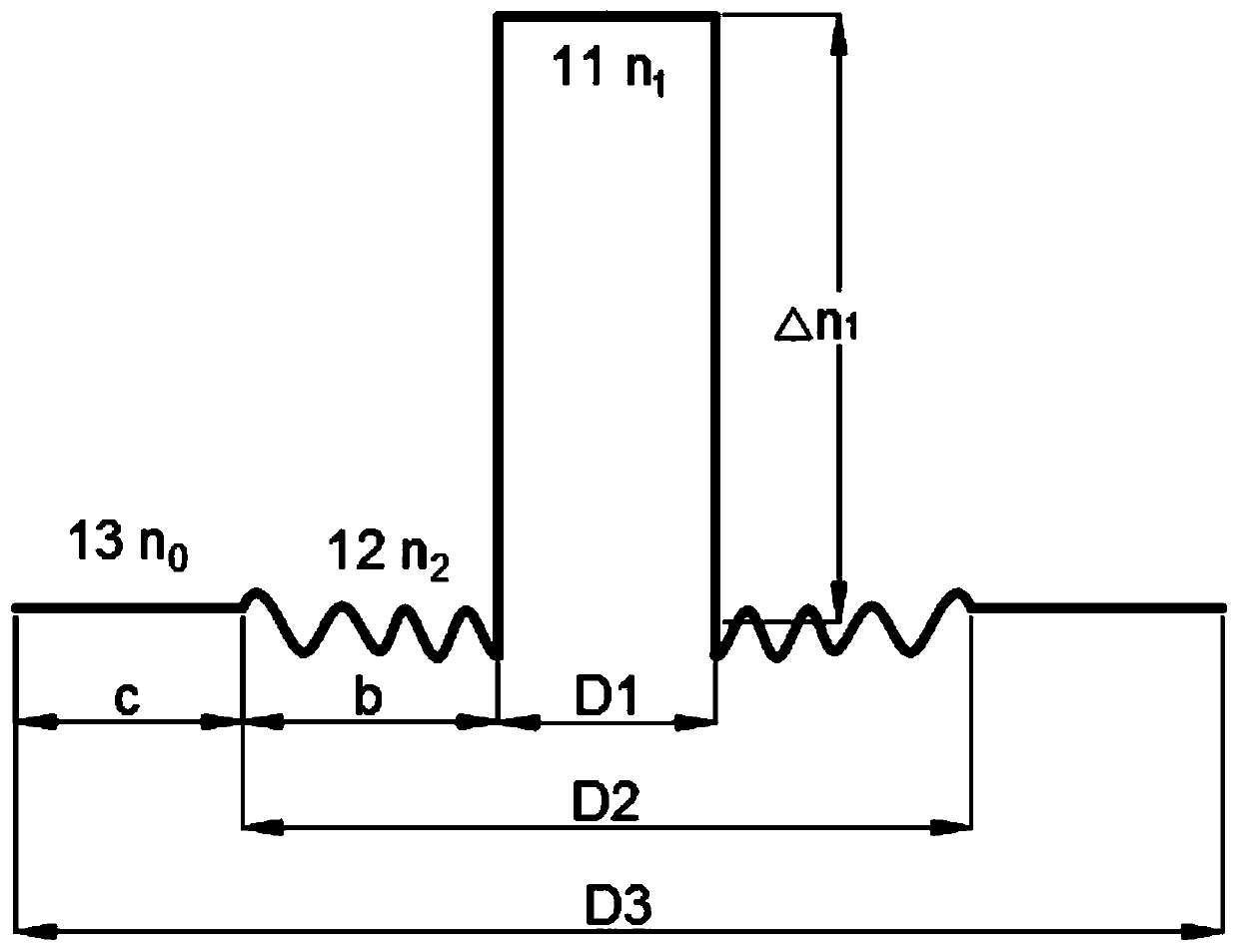

[0038]The core rod is manufactured by MCVD technology, and the optical fiber preform is manufactured by OVD technology to manufacture the outer cladding. In the quartz tube, a certain amount of GeCl4 is doped in the raw material SiCl4, wherein the ratio of SiCl4 and GeCl4 is 220:650 according to the fixed flow rate, so that the refractive index difference Δn1 of the core layer relative to the inner cladding layer is 0.00152, and the mole of the doped substance The percentages are Si: 86.8%; Ge: 13.2%, the core layer diameter D1 is 3.8um; the inner cladding layer is doped with a certain amount of GeCl4, POCL3, SF6 in the raw material SiCl4, 10 times of deposition, close to the core layer to the inner cladding layer Direction, SiCl4 according to Y=20X+500, GeCl4 according to Y=5X+200SF6 according to Y=10-0.3X POCL3 according to Y=6X+130. The final refractive index difference Δn2 between the inner cladding and the quartz substrate layer is 0.0001, and the molar percentages of the...

Embodiment 2

[0040] The core rod is manufactured by MCVD technology, and the optical fiber preform is manufactured by OVD technology to manufacture the outer cladding. In the quartz tube, a certain amount of GeCl4 is doped in the raw material SiCl4, wherein SiCl4 and GeCl4 are in a fixed ratio of 250:730, so that the refractive index difference between the core layer and the inner cladding layer Δn1 is 0.00143. The molar percentages of impurities are Si: 87.5%; Ge: 12.5%, and the diameter D1 of the core layer is 4.0um; the inner cladding layer is doped with a certain amount of GeCl4, POCL3, and SF6 in the raw material SiCl4, deposited 15 times, close to the core layer In the inner cladding direction, SiCl4 follows the flow rate of Y=20X+600, GeCl4 follows the flow rate of Y=5X+230, SF6 follows the flow rate of Y=8-0.3X, and POCL3 follows the flow rate of Y=6X+100. The refractive index difference Δn2 between the final inner cladding layer and the quartz substrate layer is 0.0000, and the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com