Energy ray-curable epoxy resin composition having excellent fast curing properties

An energy ray curing, epoxy resin technology, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

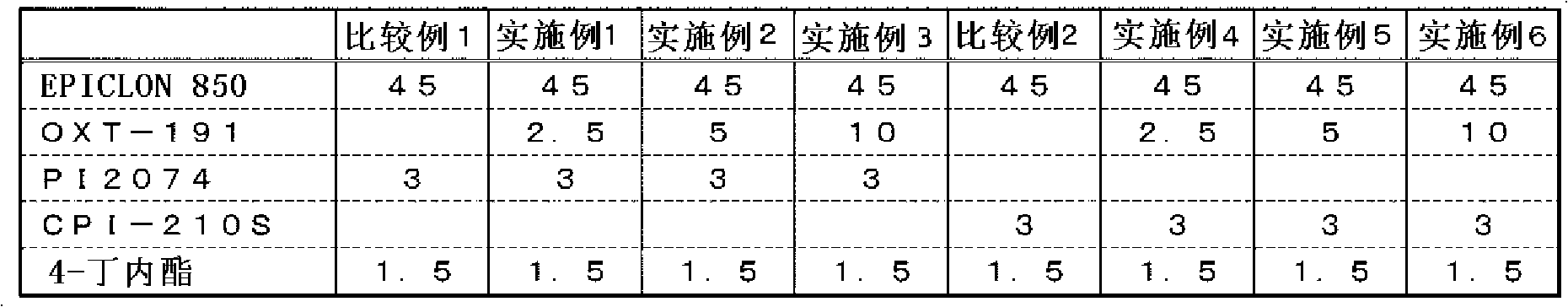

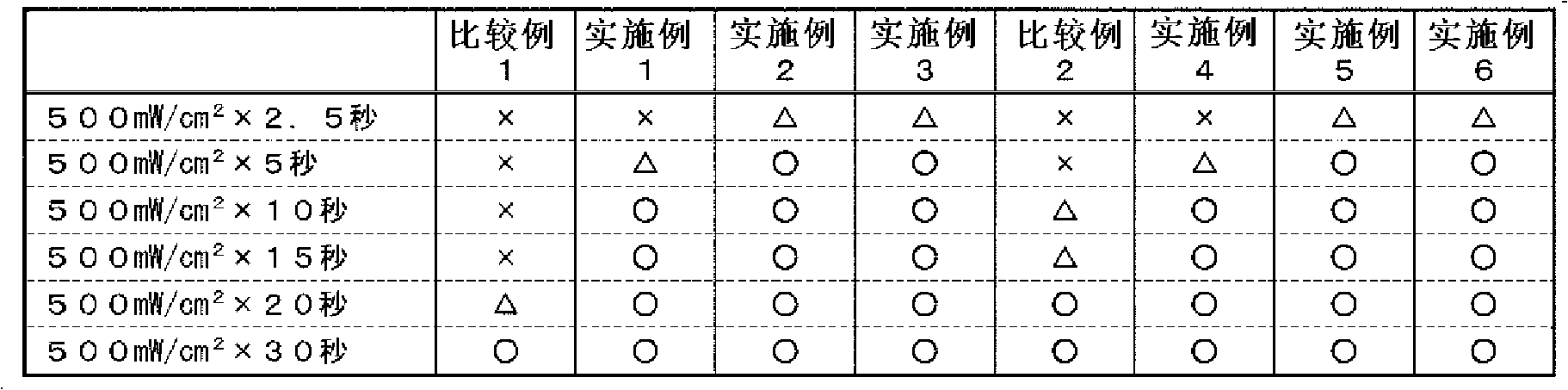

Embodiment 1~6 and comparative example 1~2

[0047] Based on the ratio shown in Table 1, the photoacid generator PI2074 or CPI-210S was dissolved in 4-butyrolactone, and added to EPICLON 850, stirred until transparent to prepare the energy rays of Comparative Examples 1 and 2 Curable epoxy resin composition.

[0048] Based on the proportions shown in Table 1, OXT-191 was added to the epoxy resin composition of Comparative Example 1 or 2, and stirred until uniform, to prepare the energy ray-curable epoxy resin compositions of Examples 1-6.

[0049] Table 1

[0050]

[0051] EPICLON 850: Bisphenol A type epoxy resin (manufactured by DIC Corporation)

[0052] OXT-191: Oxetanyl silicate (manufactured by Toagosei Co., Ltd.)

[0053] PI2074: Ionium salt-based photoacid generator (manufactured by Rhodia Corporation)

[0054] CPI-210S: Sulphonium-based photoacid generator (manufactured by San-Apro)

[0055] 4-butyrolactone: solvent (manufactured by Wako Pure Chemical Industries, Ltd.)

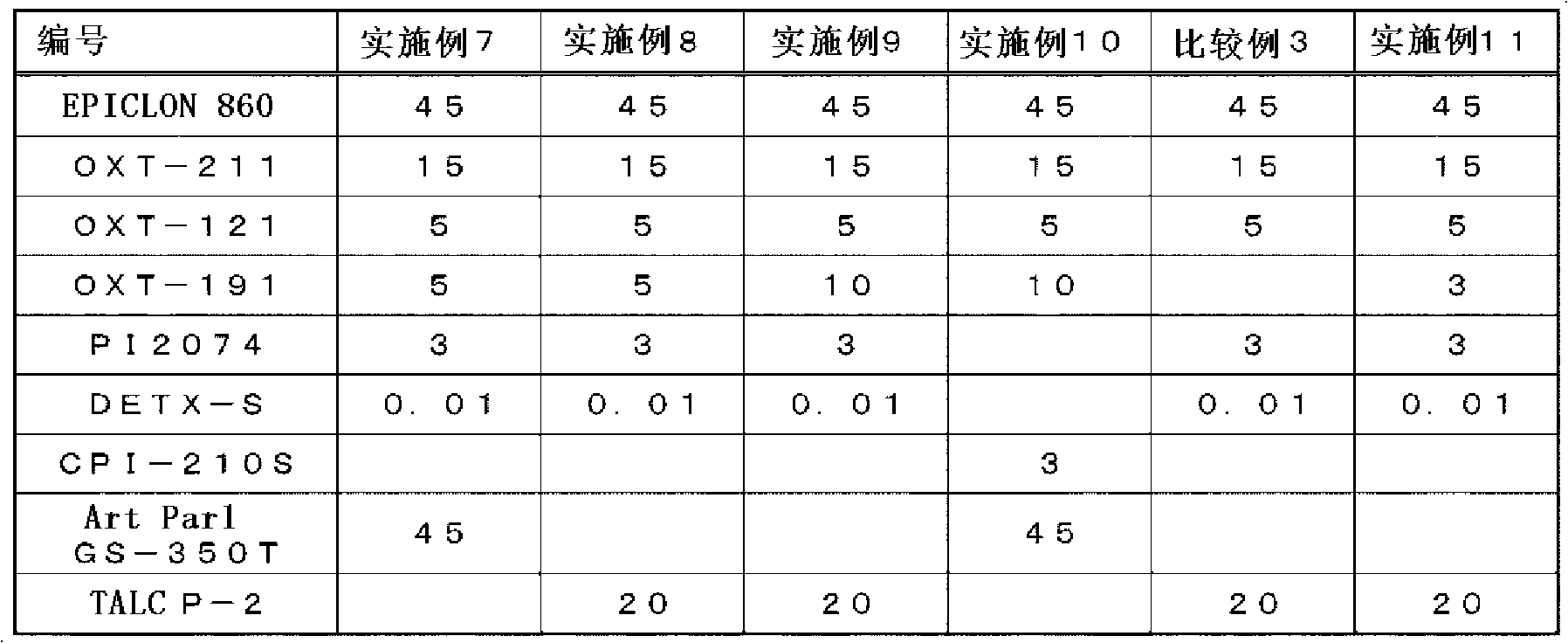

Embodiment 7~11 and comparative example 3

[0061] Based on the compounding ratio shown in Table 3, the energy-ray-curable epoxy resin composition of Examples 7-11 and the comparative example 3 was prepared.

[0062] table 3

[0063]

[0064] EPICLON 860: Bisphenol A type epoxy resin (manufactured by DIC Corporation)

[0065] OXT-211: 3-ethyl-3-(phenoxymethyl)oxetane (manufactured by Toagosei Co., Ltd.)

[0066] OXT-121: 1,4-bis[{(3-ethyl-3-oxetanyl)methoxy}methyl]benzene (manufactured by Toagosei Co., Ltd.)

[0067] OXT-191: Oxetanyl silicate (manufactured by Toagosei Co., Ltd.)

[0068] PI2074: Ionium salt-based photoacid generator (manufactured by Rhodia Corporation)

[0069] DETX-S: 2,4-diethylthioxanthone (sensitizer: manufactured by Nippon Kayaku Co., Ltd.)

[0070] CPI-210S: Sulphonium-based photoacid generator (manufactured by San-Apro)

[0071] Art Parl GS-350T: Acrylic / styrene copolymer filler (manufactured by Negami Kogyo Co., Ltd.)

Embodiment 12~14

[0082] Based on the compounding ratio shown in Table 6, the energy ray-curable epoxy resin composition of Examples 12-14 was prepared.

[0083] Table 6

[0084]

[0085] X-40-2670: Alicyclic epoxy silicate (manufactured by Shin-Etsu Chemical Co., Ltd.)

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| cure shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com