Polylactic acid-based resin composition and molded article

A technology of resin composition and polylactic acid resin, which is applied in the field of polylactic acid resin composition and moldings, can solve the problems of insufficient hydrolysis resistance and durability, and achieve excellent hydrolysis resistance, good appearance, and long-term hydrolysis resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

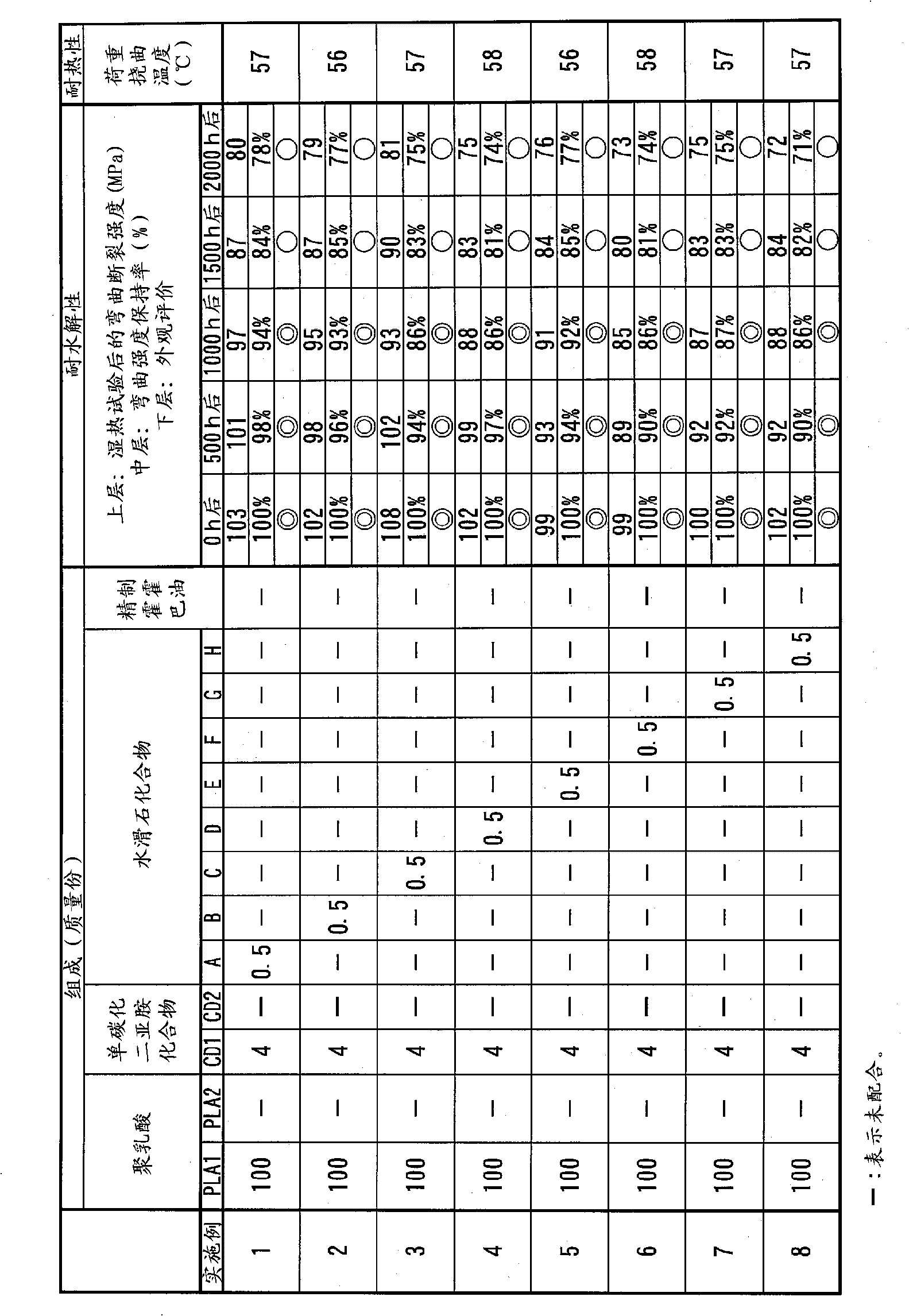

Embodiment 1

[0158] 100 mass parts of PLA1 as polylactic acid resin, 4 mass parts of CD1 as monocarbodiimide compound, and 0.5 mass parts of A as hydrotalcite compound are dry-blended, and then using a twin-screw extruder (Chibei Made by the company, brand name "PCM-30 type"), melt-kneading was carried out under conditions of a temperature of 190° C. and a screw rotation speed of 150 rpm. After melt-kneading, strands were extruded from a die with a diameter of 0.4 mm x 3 holes, cut into pellets, and dried at a temperature of 60° C. for 48 hours with a vacuum dryer (manufactured by Yamato Scientific Co., Ltd., trade name “Vacuum Dryer DP83”). Hours of drying treatment to obtain pellets (polylactic acid-based resin composition).

Embodiment 2~8

[0160] As shown in Table 1, except that B, C, D, E, F, G, and H were used instead of A as the hydrotalcite compound, the same operation as Example 1 was carried out to obtain particles of the polylactic acid-based resin composition.

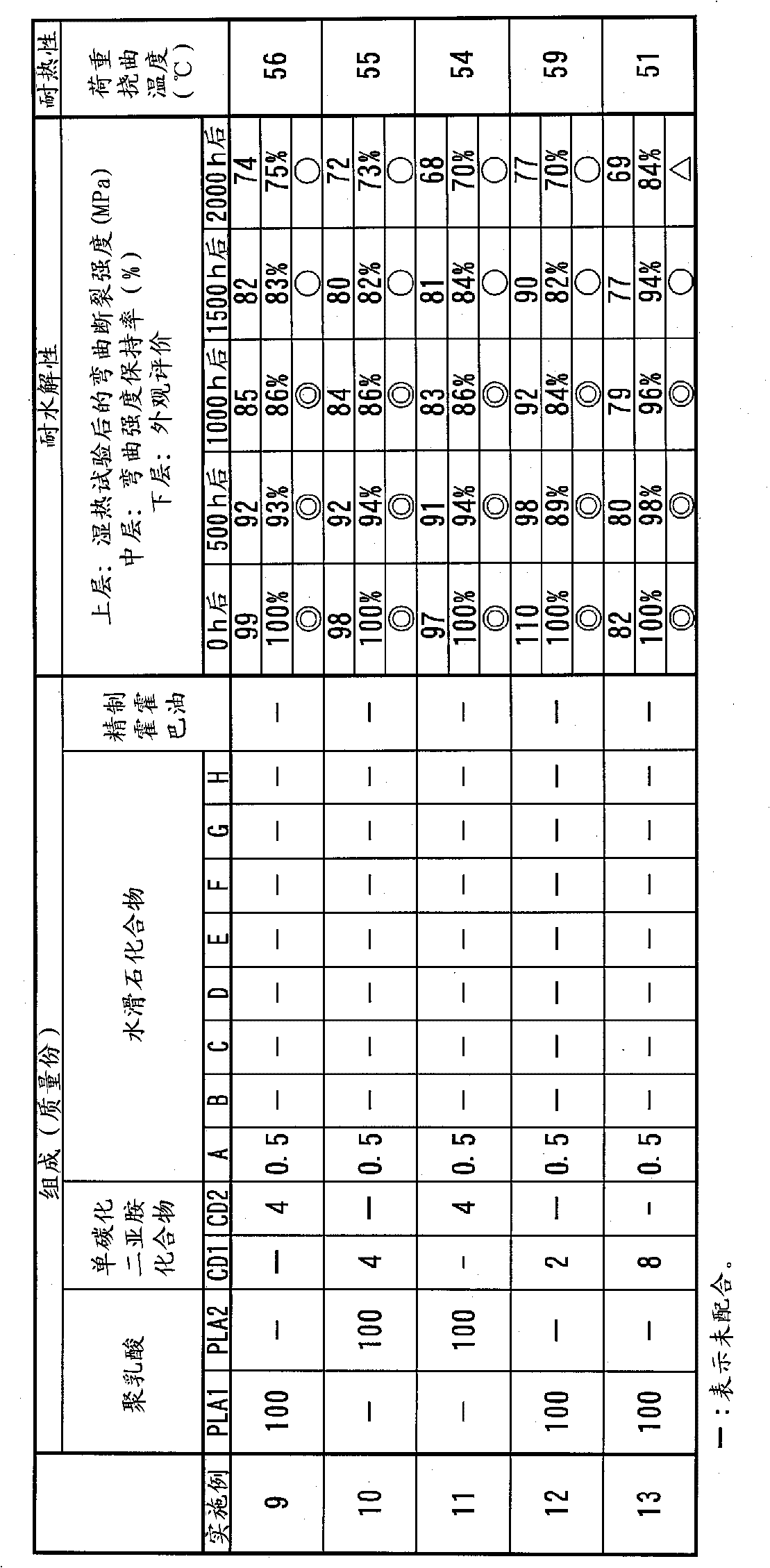

Embodiment 9

[0162] Except having used CD2 as a monocarbodiimide compound, the operation similar to Example was performed, and the pellet of the polylactic acid-type resin composition was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com