Air liquefaction and separation method and device

A technology of air liquefaction and separation method, applied in liquefaction, refrigeration and liquefaction, cold treatment separation, etc., can solve the problem that the improvement of device price cannot be called perfect, and achieve the effect of reducing device price, reducing energy and reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

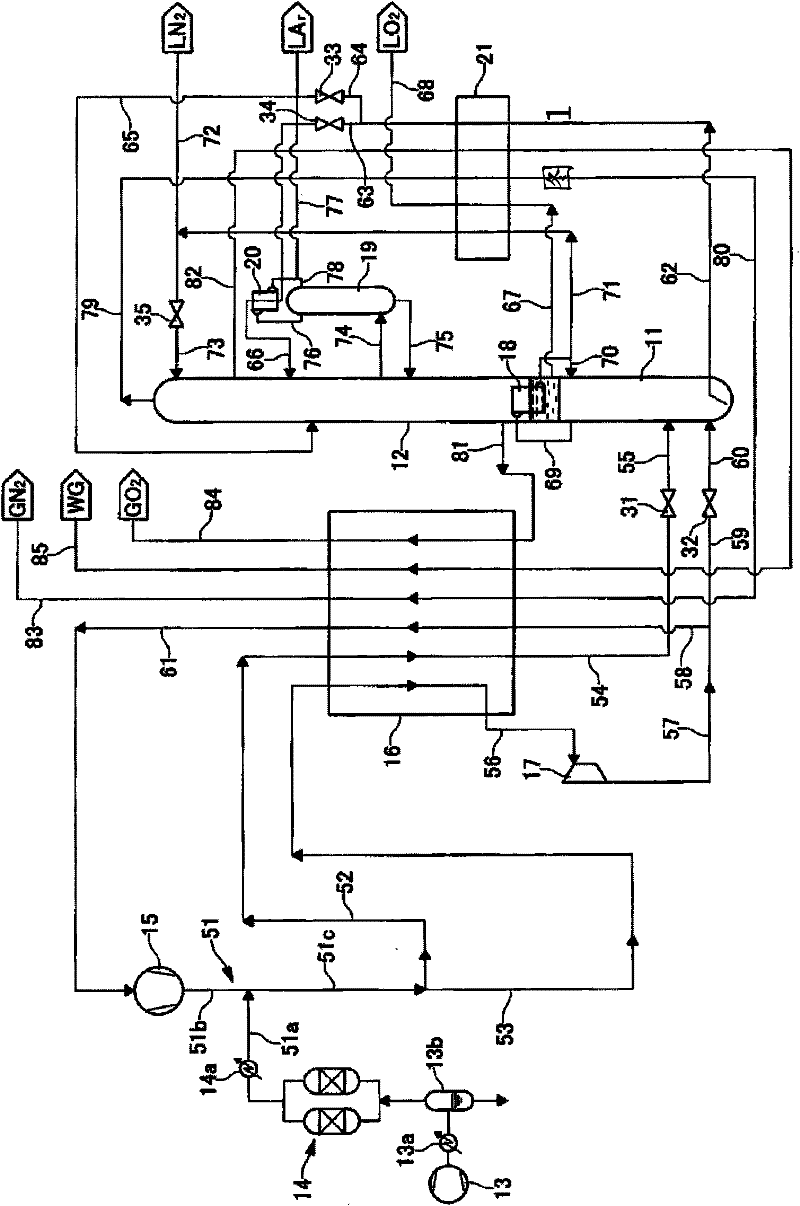

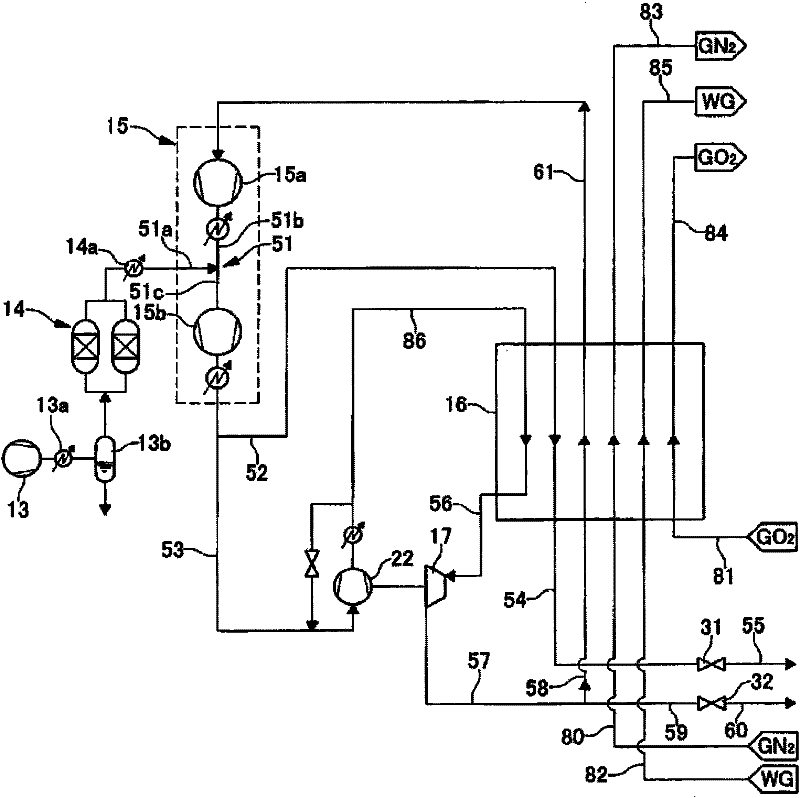

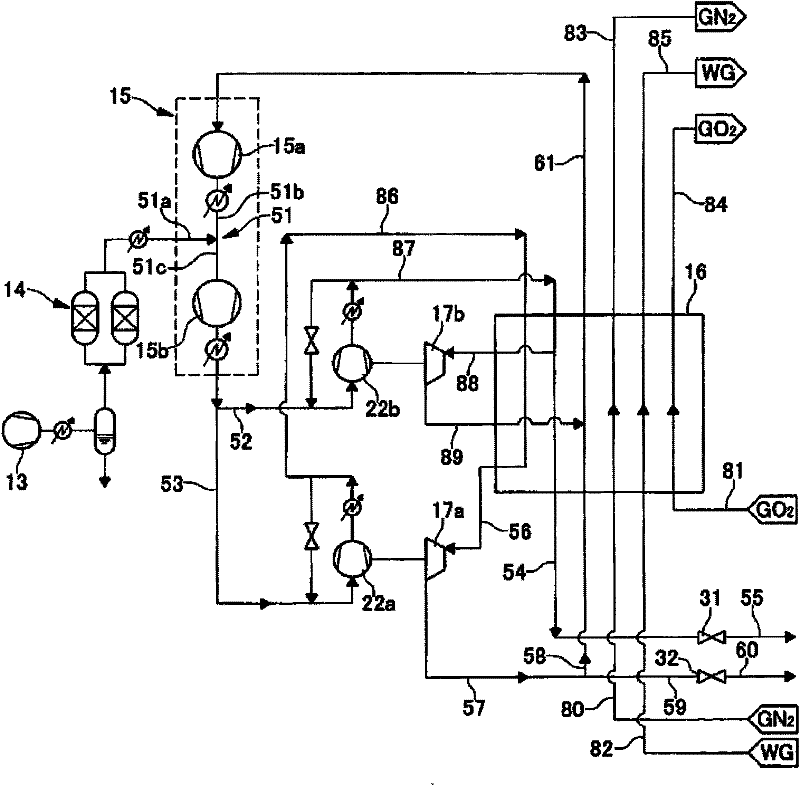

[0033] figure 1 The air liquefaction separation device shown in the first embodiment is to convert liquid oxygen LO 2 , liquid crude argon LAr and liquid nitrogen LN 2 Extraction as a liquid product and oxygen GO 2 and Nitrogen GN 2 The air liquefaction separation device that extracts as a gaseous product, as the main component device, this air liquefaction separation device has a raw material air compressor 13, an adsorption device 14, a circulation compressor 15, a main heat exchanger 16, a turbo expander 17, a main Condenser 18, crude argon tower 19, argon condenser 20, subcooler 21.

[0034] First, the entire raw material air is introduced into the raw air compression step. In the raw air compression step, the raw air compressor 13 is used to raise the pressure of the entire raw air to a first set pressure higher than the operating pressure of the medium-pressure column 11 to form Raw air for pressurization. The pressurized raw air is cooled by the cooler 13a, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com