Wet treatment device and wet treatment method

A wet processing and substrate technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of wet processing liquid retention and deterioration of the uniformity of the substrate being processed, and achieve the effect of improving the uniformity of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

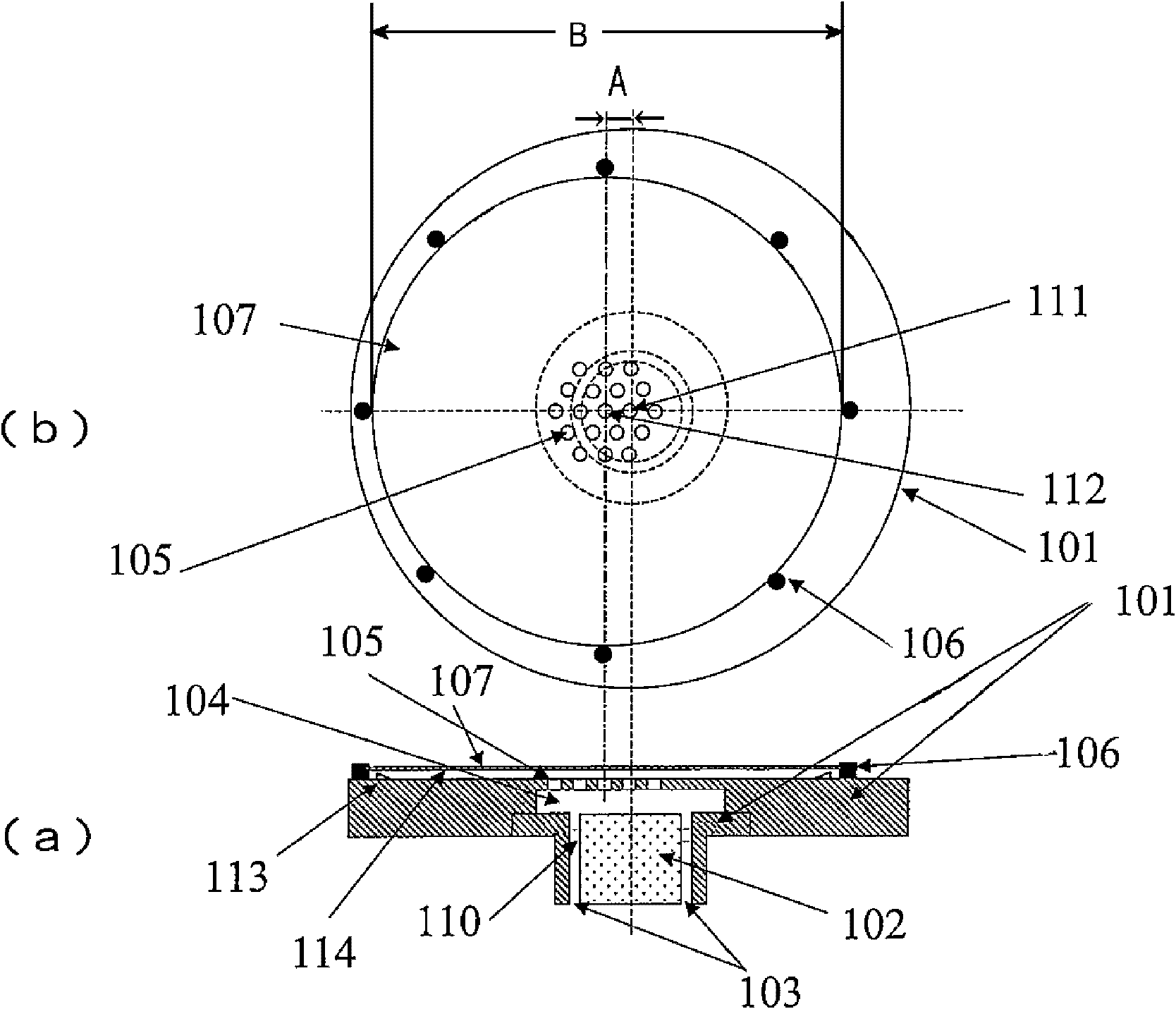

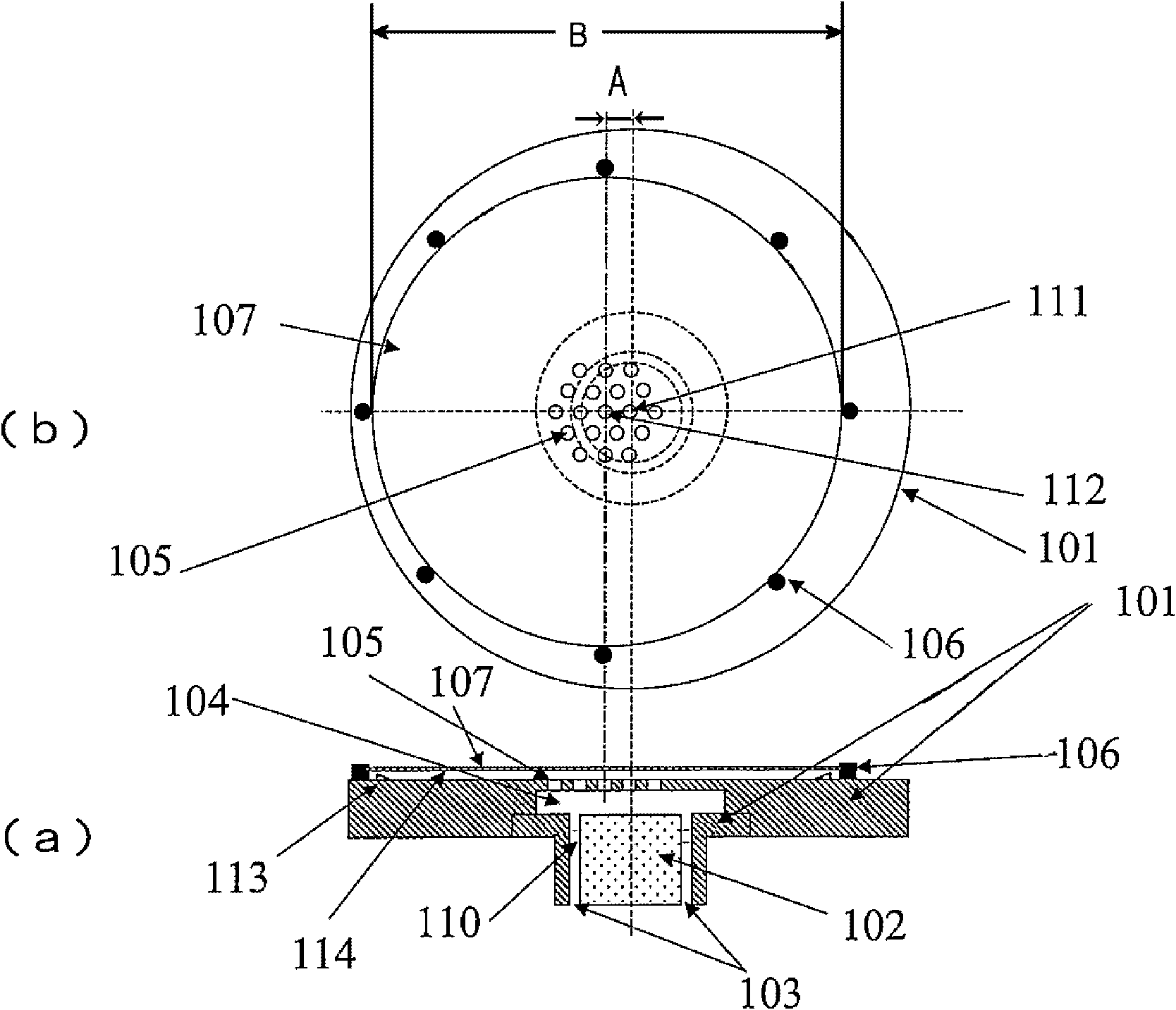

[0021] refer to figure 1 A first embodiment of the wet processing apparatus of the present invention will be described. figure 1 It is a longitudinal sectional view of the peripheral part of the workbench of a wet processing device with a Bernoulli suction cup ( figure 1 a) and top view ( figure 1 b).

[0022] The wet processing apparatus holds a circular substrate 107 having a diameter of 300 mm on a circular table 101 and performs wet processing by rotating the table 101 . The table 101 rotates around a fixed central axis 102 . The distance between the center of the processed substrate 107 indicated by 112 and the center of the table 101 indicated by 111 is 11.25 mm. That is, the distance between the center 111 of the table 101 and the center 112 of the substrate 107 to be processed, that is, the eccentricity A and the diameter B of the substrate 107 to be processed satisfies the relationship of A=C×B when C=0.0375. 103 is an inert gas inlet for a Bernoulli chuck. 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com